The test was conducted under the full supervision of internationally recognized third-parties, TÜV Rheinland and North American fire engineering consultancy Hiller, and executed in accordance with the latest NFPA 855:2026 & UL 9540A:2025-11 safety standards, under conditions more stringent than standard industry requirements.

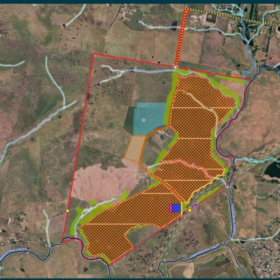

A real-site layout — intensified far beyond test limits

- 10 cm cabinet spacing — heat concentration intensified

Containers were arranged side-to-side at only 10 cm, far below the 60 cm standard distance, minimizing heat dissipation and increasing thermal stress.

- Maximum energy configuration — 100% SOC full installation

The initiation container was ignited with all modules installed and charged to 100% SOC, maximizing thermal runaway.

- Fire suppression disabled — safety design fully tested without intervention

All automatic suppression and active extinguishing functions remained OFF throughout the test, requiring the system to rely solely on its structural isolation and engineering-level safety design.

- Explosion-vent panels and ventilation system kept open — oxygen flow boosted

Explosion-vent panels and ventilation system remained open to intensify oxygen flow, increasing combustion strength and thermal load beyond real-world failure scenarios.

Despite these extreme conditions, Elementa 2 Pro maintained structural stability and controlled thermal behavior — demonstrating complete end-to-end safety performance from cell to system.

Elevating industry safety standards to new heights

Throughout the entire test, the initiation container maintained structural integrity without any collapse, while no thermal propagation occurred in adjacent containers.

Additionally, the UPS within the initiating container remained functional, and the electrical cabinet was preserved intact, validating spatial layout, electrical isolation and equipment protection strategy. Cell temperatures remained below 43.9°C in the back-to-back container and 23.9°C in the side-by-side container — both far beneath the cell venting point.

From field validation to grid-level operation

This large-scale fire test not only validates resilience under extreme boundary conditions, but also reflects Trina Storage’s commitment to safety-first engineering and system-level innovation.

Trina Storage will continue to push safety technology forward, working with customers, regulators and partners worldwide to build a safer, more resilient and high-quality clean energy future.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.