Supported by the Australian and UK governments through their Renewable Hydrogen Innovation Partnership, the $1.5 million (USD 980,000) study is evaluating the potential integration of Supercritical’s ultra-efficient, high-pressure electrolyser technology into HAMR Energy’s hybrid methanol plant design.

The initial study demonstrates that integrating Supercritical’s novel high temperature and pressure electrolysis into the methanol synthesis process leads to cost savings associated with efficiency gains.

The study is part of HAMR Energy’s commitment be the primary solution provider for LCLFs, producing fuel at lowest cost. Results show continued levelised cost of methanol reductions for its future plants over and above the highly-competitive present state offered with the first phase of their Portland Renewable Fuels facility in Victoria, Australia.

In October 2025, HAMR Energy and Supercritical Solutions met in Melbourne with some of the industry’s leading players to share the progress of their collaboration.

The study now moves into its final phase with completion expected by the end of the year ahead of Supercritical’s first of a kind demonstration which will pave the way to commercialisation.

David Stribley, Co-Founder of HAMR Energy, said: “HAMR Energy is rapidly advancing renewable fuels projects to meet the growing demand for clean fuels. The partnership with Supercritical provides a pathway to further reduce production costs for future projects as they commercialise their technology.”

“It is also an example of government-backed global collaboration fostering innovation that can play a significant role in the world’s efforts to decarbonise. We thank the Australian and UK government for their ongoing support for LCLF, which present huge economic and decarbonisation opportunities for both countries.”

Luke Tan, Co-Founder of Supercritical, said: “It’s exciting working with a company who is as driven and passionate about making low carbon fuels economically viable.”

“Partnering with HAMR Energy is allowing us to demonstrate how our electrolyser technology can be applied at scale in real-world industrial settings. The study is currently showing that low carbon methanol can be produced more efficiently and affordably, and we’re proud to be contributing to a cleaner fuels future.”

The project also involves collaboration with UK partners Astrimar Ltd and the Manufacturing Technology Centre (MTC) in the UK, as well as Monash University in Melbourne. Supercritical’s mission was significantly boosted earlier in 2025 upon securing 14 million pounds in a capital raise that included backing from Toyota Ventures and Shell Ventures.

The ongoing progress of the study comes as the Australian government opens Round 2 of its Hydrogen Headstart Program, offering $2 billion in funding to accelerate commercial-scale renewable hydrogen projects.

The new round prioritises feedstock-based applications including shipping and aviation fuels, and builds on strong tailwinds for the LCLF industry, including dedicated funding to support supply and demand being driven by mandates.

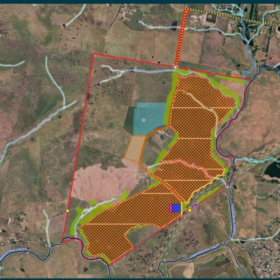

HAMR Energy’s most advanced project, Portland Renewable Fuels, will convert forestry residues and low carbon hydrogen into 300,000 tonnes of low carbon methanol per annum for shipping and aviation fuels.

As well as Portland Renewable Fuels, HAMR Energy is developing a pipeline of opportunities and relationships across the renewable fuels sector, offering a vertically integrated platform that mirrors a traditional fuels business.

Based in regional areas, the projects will increase local fuel manufacturing capacity, create long-term direct jobs and support other critical regional industries including forestry and agriculture.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.