During the two-day inspection, Redflow directors saw factory staff fully assemble two ZBM2 zinc-bromine flow batteries which are now undergoing post-production acceptance testing.

Redflow Chairman Brett Johnson said the board had been pleased by progress at the factory. “We are impressed by the commitment of the on-site team to producing high-quality components,” he said.

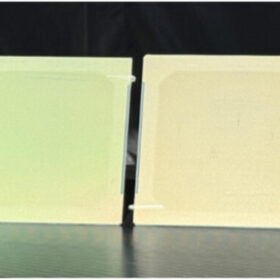

“While we were there, we saw the first two complete ‘made in Thailand’ batteries come off of the line. These are now undergoing quality and performance testing.

“The current production of battery stacks and this preliminary demonstration of full battery assembly means that we remain on track to commence production of complete batteries in Thailand by June.

“In the meantime, we will continue to assemble ZBM2 batteries in Brisbane using Thai-made battery stacks to satisfy customer backorders.”

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.