From pv magazine India

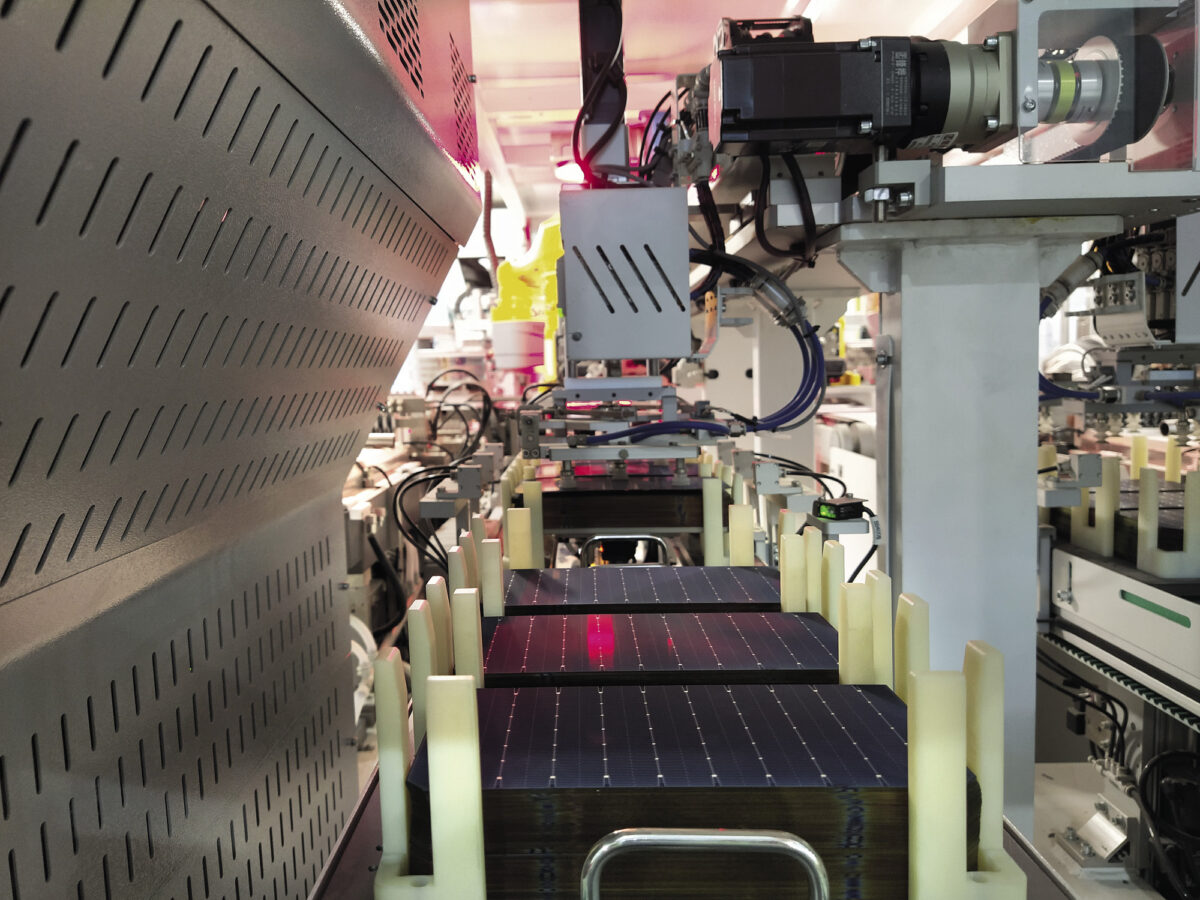

India is set to reach 110 GW of solar PV module capacity by fiscal 2026, with 72 GW of new manufacturing capacity to go online within the next three years. The significant jump will establish self-sufficiency and make the nation the second-largest PV manufacturing country after China, according to a new report by the Institute for Energy Economics and Financial Analysis (IEEFA) and JMK Research.

The report says India will have a notable presence in all upstream components of PV manufacturing. It claims that cell capacity will reach 59 GW by fiscal 2026, ingot/wafer capacity will hit 56 GW, and polysilicon will touch 38 GW.

“The future of the Indian PV manufacturing sector is bright,” said the report’s co-author Vibhuti Garg, director of South Asia for IEEFA. “The favourable policy environment created by the Indian government is helping the PV manufacturing industry to grow rapidly, which is evident in the frequent announcements of expansions or new investments in the sector.”

The report shows that India’s cumulative module manufacturing nameplate capacity more than doubled from 18 GW in March 2022 to 38 GW in March 2023.

“The production-linked incentive (PLI) scheme is one of the primary catalysts spurring the growth of the entire PV manufacturing ecosystem in India,” said Jyoti Gulia, the founder of JMK Research. “Besides the augmentation of infrastructure in all stages of PV manufacturing, from polysilicon to modules, it will also lead to the simultaneous development of a market for PV ancillary components, such as glass, ethylene vinyl acetate (EVA), and backsheets.”

The results of both tranches of the PLI scheme show that there will be an increase of 51.6 GW of module capacity and at least 27.4 GW of integrated “polysilicon-to-module” capacity in India in the next three to four years.

While the PLI scheme is a supply-side measure, the government has also taken steps to increase demand for locally made solar modules. One such step was the introduction of domestic content requirements (DCR) for solar power in several government schemes, including the Pradhan Mantri Kisan Urja Suraksha Evam Utthaan Mahabhiyan (PM-KUSUM) Scheme and the Central Public Sector Undertaking (CPSU) Scheme.

One of the key steps taken by the government to drive up demand for domestic PV modules was the introduction of the Approved List of Module Manufacturers (ALMM) in 2019. The report notes that even after applying higher basic customs duty (BCD) on imported modules, the cost differential compared to domestic modules is negligible.

“In such a scenario, the ALMM acts as an absolute trade barrier protecting the interests of domestic manufacturers. Thus, over the past year, ALMM has been the most important driver for the development of domestic PV manufacturing,” said Prabhakar Sharma, a consultant for JMK Research. “The latest ALMM list, updated on 27 February 2023 by the Ministry of New and Renewable Energy, includes 70+ domestic manufacturers with an enlisted capacity of 22,389 MW.”

The report also identifies obstacles holding back the domestic PV manufacturing industry. Chief among them is an over-reliance on Chinese imports for upstream components of PV modules, such as polysilicon, ingots, and wafers.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.