Researchers at the University of New South Wales (UNSW) have reported research details of their improved sieving separation method to enhance the recovery of silver and other metals from end-of-life solar panels. The technology has been patented.

“The method relies on a simple mechanical sieving process and is enhanced with sieving aids (stainless steel balls), which are low-cost, durable, and widely available,” corresponding author, Yansong Shen, told pv magazine, adding that the efficient separation of PV cells from other components facilitates high-value recovery of silicon and other valuable metals, making it “economically attractive.”

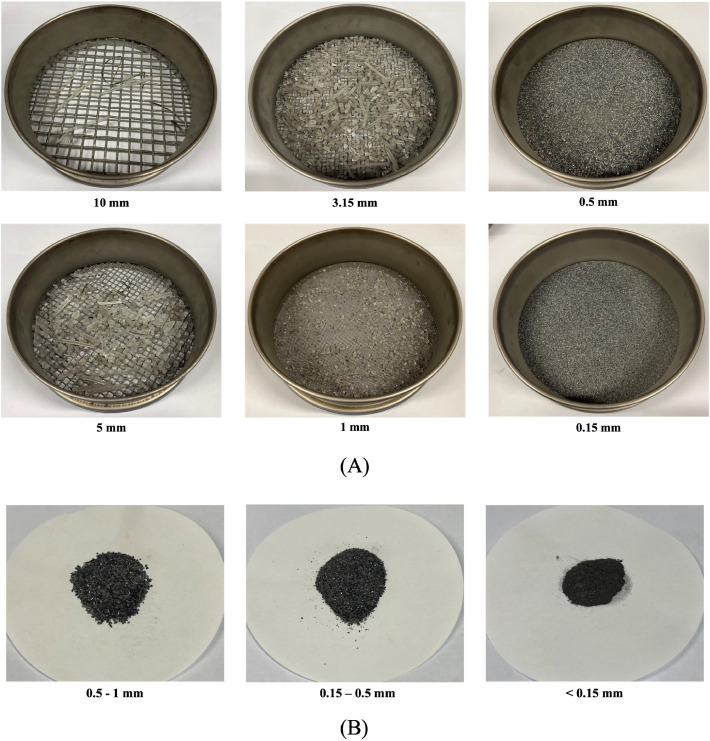

The sieving process comes in after the pyrolysis delamination upstream step and before the chemical leaching downstream step for silver recovery.

In the experimental work, the team used monocrystalline silicon PV panels, standard ethylene vinyl acetate (EVA) encapsulants, protective cover glass and a foil back sheet in an anodised aluminum alloy frame.

These were processed via thermal delamination for polymer removal, mechanical separation, and chemical leaching. Then samples were extracted. Measurements of the samples included particle weight and size, as well as scanning electron microscopy (SEM).

“The results indicate that over 96.3 wt.% of the chip-like PV cell particles can be separated from the debris mixture under the optimized sieving conditions using the new sieving aids technology, compared to the separation rate of 31.7% in the conventional sieving methods,” according to the research.

“The leaching result shows that over 98.9% of the silver contained in the PV modules can be recovered by this integrated method,” reported the team.

The research appears in “Improving particle separation and recovery of valuable materials from end-of-life solar panels,” published by Resources, Conservation and Recycling.

Regarding commercialisation potential, Shen said that although the current results were obtained at the lab scale, the method could be developed into a practical product and integrated into industrial PV recycling lines through further optimisation and scale-up.

The researchers plan to continue to develop and improve the proposed separation method, with a focus on industrialisation, and to investigate the thermal delamination process to develop a more “sustainable and effective approach for polymer removal.”

There is ongoing activity at the national Research Hub for Solar Panel Recycling and Sustainability where the researchers work with industry partners to commercialize recycling technology and invent new PV recycling technologies.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.