Aviation accounts for approximately 12% of global carbon dioxide emissions. With intensifying climate change and environmental issues, the aviation industry is searching for greener propulsion systems.

For unmanned aerial vehicles (UAVs), which have wide applications in military, logistics, and agriculture, research has turned towards hydrogen propulsion systems. Hydrogen is a clean fuel that produces only water during combustion, representing a promising alternative to conventional fossil fuels.

However, hydrogen has low volumetric energy density, meaning larger volumes are required to produce the same energy as conventional fuels. One solution is liquid hydrogen storage systems, where hydrogen is stored at cryogenic temperatures in liquid form.

While this reduces storage size and weight, it also presents various challenges, including vessel deformation due to thermal stresses in cryogenic temperatures and fatigue failure.

This is particularly risky in UAV operation conditions, which involve multi-directional acceleration loads. A comprehensive assessment of thermal performance and structural integrity in UAV operation conditions is, therefore, crucial. However, despite extensive research, an analytical framework for assessment of liquid storage systems in UAVs is still lacking.

Image: Dr. Nak-Kyun Cho from Seoul National University of Science and Technology, Korea

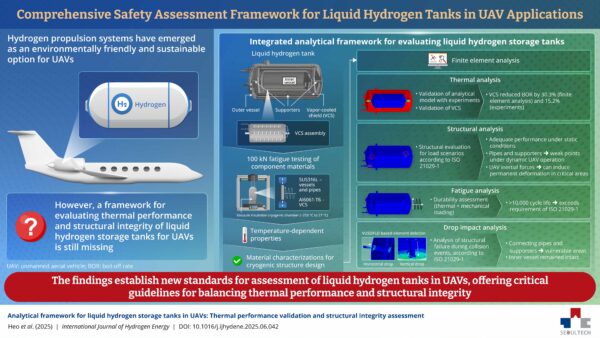

To address this gap, a research team led by Assistant Professor Nak-Kyun Cho and Mr. Jinmyeong Heo from the Department of Manufacturing Systems and Design Engineering (MSDE) at Seoul National University of Science and Technology, Korea, in collaboration with Professor Nam-Su Huh from the Department of Mechanical System Design Engineering at the same university, developed the first integrated analytical framework for evaluating the performance and structural integrity of liquid hydrogen storage tanks in UAVs.

“Unlike existing studies that mostly were limited to isolated thermal insulation performance or structural analyses, we have developed the first holistic system integrating thermal, structural, fatigue, and impact analyses, specifically tailored for UAV operations,” explains Dr. Cho.

Their study was made available online on June 09, 2025, and published in Volume 145 of the International Journal of Hydrogen Energy on July 07, 2025.

The team began by obtaining cryogenic properties of the materials used in the storage systems with the support of research funding and material testing and verification of the Hydrogen Materials Research Center at Korea Institute of Materials Science (KIMS).

They considered a standard liquid hydrogen storage tank, consisting of inner and outer vessels, pipes, and supporters, made using SUS316L steel. Additionally, the vessel included vapor-cooled shield (VCS) that reduce the entry of heat into the system, made from Al6061-T6 aluminium.

Temperature-dependent properties of these materials were measured using a 100 kN tensile-fatigue testing system. These properties were then incorporated into finite element analyses of the vessel, covering thermal, structural, fatigue, and drop impact assessments.

Thermal analysis revealed that the VCS implementation reduced the boil-off rate (BOR) by 30%. BOR is a key performance indicator that represents the rate at which stored liquid hydrogen is converted to gas due to unavoidable entry of heat into the storage system.

In experiments, the BOR was reduced by 15%, a difference attributed to simplifications in the model. Structural analysis revealed pipes and supporters as the weak points under UAV-specific operational conditions, highlighting the need for structural modifications.

Fatigue analysis showed that the vessel far exceeded the 10,000 cycle requirement specified in ISO 21029-1 standards, with an effectively unlimited fatigue life.

For drop impact testing, the team developed a new computer simulation method using a VUSDFLD subroutine-based element deletion approach to predict how tanks behave when dropped from a height.

This analysis identified connecting pipes and supporters as vulnerable areas, while demonstrating the ability of the approach to predict failure behaviour of multi-material component systems.

“Our findings establish new standards for comprehensive safety assessment of liquid hydrogen storage tanks in UAV applications,” notes Mr. Heo. “Moreover, our established cryogenic material database will also be an important reference for future designs in aerospace field. Ultimately, this framework will serve as a valuable reference for establishing design standards or criteria for hydrogen-powered UAVs, enabling longer flight durations, rapid delivery services, and more sustainable operation.”

We hope this new framework will be widely adopted, paving the way for more sustainable and eco-friendly UAV propulsion systems.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.