pv magazine: You presented recently at the Plenary Session at the WCPEC-7 conference in Hawaii. You presented then using the name Ciesla neé Wenham. Why is that?

Alison Ciesla (neé Wenham): In some ways, it was difficult living in my dad’s shadow, because there are a lot of implications that come with that and occasions that people think your work is not entirely your own doing. I did end up making the decision to change my name when I got married just over two years ago.

I guess the reason I have started using neé Wenham, when my dad passed away I honestly had a few regrets about changing my name. When presenting his work, I wanted it to be recognized that it is his work, and I am presenting it on his behalf. So, I wanted to link myself to him now that he is not around.

And the paper you presented in Hawaii tells the story of the role of hydrogen in c-Si cells. How could you sum up its message?

The background to the whole thing is that my dad was always interested in the role of hydrogen in silicon – throughout his whole career. The reason for his interest in hydrogen is that it can do so much magic in that it can passivate and make any defect irrelevant – if it is controlled properly. He was really excited by that and spent years developing amazing passivation solutions that improve the quality of cells just by using hydrogen. Throughout this time, we were trying to get more-and-more hydrogen into the cells to do more passivation until there came a point when my dad realized that we were getting too much hydrogen in and it was actually starting to cause a problem.

What does it mean for the industry today?

As we are moving to higher efficiency structures, we are getting more hydrogen in. With PERC cells, we now have hydrogen sources on the front and the back of a cell. Higher efficiency structures also only take a small amount of defect to have a large impact on the efficiency. So, it’s becoming a more severe issue.

This degradation that we see with the hydrogen is very long-term degradation – it takes a long time to form and recover. It is not well understood by many people, particularly investors, consumers, manufacturers and even a lot of researchers. This means that it is not tested for effectively. There is a lot of work going on globally to develop a proper test to be able to determine this degradation, and what kind of impact it could be having on commercial cells and modules.

One of issues you raise in this recent paper is that Light and Temperature Induced Degradation (LeTID) could more accurately be described as Hydrogen Induced Degradation, is that right?

I think that LeTID is a name that has really stuck. But the actual type of degradation can be formed in the dark – so you don’t need the light at all. But that name has stuck because typically when testing for this degradation we would use those conditions.

Even here it gets more complicated, in that it is not only the hydrogen, it is the state of the hydrogen in the cell. Which links into the Advanced Hydrogenation techniques that you’ve been developing, is that right?

Absolutely. The territory that we are getting into now is that we recognize that there is a huge importance for hydrogen passivation. We wouldn’t get the efficiency we get in cells without some form of passivation, even if we are just talking surface passivation. In some of the latest results that we have at UNSW we’ve managed to do p-type multi-crystalline heterojunction structures, with voltages over 700mV – which is almost equivalent to the PERL cell record that held the efficiency record for 10 to 15 years at 24%, but using Float-Zone silicon [rather than Czochralski] with hydrogen passivation. My dad would say it’s really important to maximize the hydrogen but clear out the excess and remove hydrogen that could be problematic. It’s all about controlling the hydrogen.

What does that mean, controlling the hydrogen?

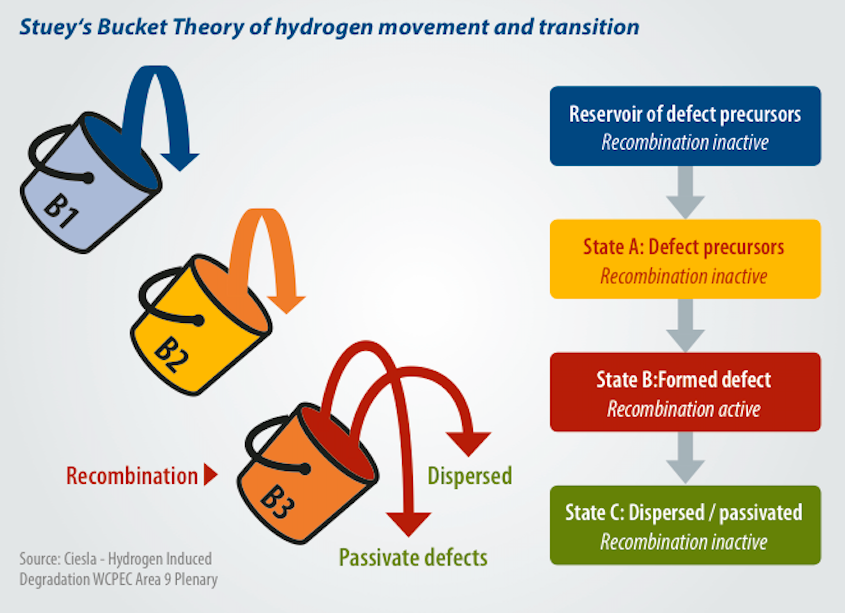

Hydrogen can store itself in many ways – my dad would call them ‘buckets’. After you would fire a cell to create the contacts, that would distribute the hydrogen throughout the silicon. Hydrogen would then bond to multiple things: it would bond to the lattice, to impurities, to itself – it would sit almost anywhere. And depending on what the hydrogen is bonded to, those bonds can be broken under different conditions.

There are a number of techniques that can be used for changing the charge state of the hydrogen and manipulating it. Depending on the temperatures that you use, the charge state and things like that, it will determine what bonds it will form, whether those bonds are stable, and whether it will move. Ultimately, we want to get the hydrogen in, control it in a way in that it will bond to what we would like it to, and then clear out the excess through using thermal processes – to clear out what we think are the problematic buckets.

That ‘Bucket Theory’ to which you refer is a nice explanation of the different role that hydrogen can play in the cell – that helps explain some of the complex behavior of the cells themselves. Why do you think ‘Bucket Theory’ is useful?

Something my dad did really well was take a complex subject and make it something that anyone could understand. This was the way that he explained the theory to us in the beginning: There are multiple places that hydrogen is stored, and it gets released over time and at certain stages it can cause problems. Also, that ultimately once the hydrogen has been released from the different buckets, they will all be empty and there no longer will be a problem. He was always saying, “we have to clear all of these buckets” and it made it easier to discuss.

There are still a lot of unknowns in terms of the role of hydrogen. Are you making progress?

We definitely are. There is a lot of progress and it is an interesting question because there are a lot of our team looking at different solutions. But in a way the industry doesn’t care as much about proving the fundamentals – is it hydrogen or not – they just want a solution. We have solutions, that is not a problem, like techniques to remove the hydrogen and control it, but now we are adapting those techniques to new materials and structures and figuring out how that all works.

UNSW received a big funding boost in December 2017, courtesy of a $29.2 million grant from the Australian Renewable Energy Agency. I understand your group received some of that. What has been its impact?

The day my dad was rushed to hospital with the tumours in his brain causing problems, it was the same day that it was announced that UNSW had won four new multi-million dollar projects on the hydrogenation – applying it different materials, and structures. At the workshop with our industry partners there was a lot to present. Where there once was one project there are now five big projects on which we wanted to update all of the partners. There are results coming in on a range of different things. It was a really good opportunity to present what we have been finding, but also finding out what they have been doing. Manufacturers now are starting to go different ways – a lot of them are wanting to go into passivated contacts, HJT cells, making it important for us to connect with them. We also wanted to show them that the team is still going really well, despite having lost my dad – who was a really great link between the groups and them. You met my dad, and you know what he was like. He was very good at managing relationships.

Stuart also had that long experience in China. Was that a major help?

He was also someone who was great at creating links for us as well. Quite a lot of us within the group had links with the companies as well. He was quite good at not only maintaining relationships on his own, but a lot of us have spent time with our partners as well.

Just to touch on the four different projects. There are still a lot of unknowns in terms of the role of hydrogen. Are you still making progress?

We definitely are. There is a lot of progress and it is an interesting question because there are a lot of our team looking at different solutions. But in a way the industry doesn’t care as much about proving the fundamentals – is it hydrogen or not – they just want a solution. We have solutions, that is not a problem, like techniques to remove the hydrogen and control it, but now we are adapting those techniques to new materials and structures and figuring out how that all works.

In terms of proving whether or not it is hydrogen responsible for the degradation, that is a totally different ball game. There is some room to investigate that in some of the projects we have, but it is not a key focus. That is something that we are trying to form some special collaborations with academic institutes around the world, to work on that level and prove what is going on.

Is there equipment and processes currently being used related to the hydrogenation techniques in production?

Our Advanced Hydrogenation for passivating boron-oxygen is definitely in full force. I think every manufacturer is using some form of that – whether that is our technique or light and head, or the equivalent technique using current, which is known as the ISC Konstanz technique. But they have the same effect and every manufacturer is using some form of hydrogenation to passivate those defects.

That process and tools for that will do a reasonable job, far better than doing nothing at all, is solving the LeTID by controlling the hydrogen charge state so that it can passivate boron-oxygen defects, you are simultaneously using the hydrogen that could be causing LeTID. There are three solutions out there on the market and that can help the LeTID to a certain extent. We are currently working with tool manufacturers at the moment and will have a tool, possibly by the end of this year, that will be able to do a significantly better job at reducing the HID or LeTID.

Photo: pv magazine/Dave Tacon

On a personal note, what does it mean for you to be continuing you father’s work, in which you’ve been deeply involved for some time?

I did my PhD in the space, because he was very enthusiastic and passionate, and you would have noticed he is quite contagious. He never tried to convince me to do anything, but he would talk about his work with such passion that it was contagious. There are depressing moments during a PhD where you are stuck on your own project and not getting results, and he told me, “you’re doing such great work and don’t you want to continue?” So, I agreed to stay a little longer and then it wasn’t long before he got really sick and passed away. Since then my motivation for work has drastically increased.

Now I think I feel my dad’s passions, where possibly before I might have felt like I was doing his work. I was making my own decisions on what I did, but it still felt like I was just part of his group, doing what he wanted, and I always wanted to do my own thing. Now that he is not around, I feel like I am doing everything because I want to do it.

And it’s important work as well!

It is! And I feel that with developing standards in terms of identifying modules and cells that would be susceptible to HID, myself and my group has a better understanding than anyone else in the world – with perhaps the exception of Q Cells, which has great solutions but doesn’t publish a lot – so I feel I big responsibility to do something about that. I feel that we need to help the industry produce cells and modules that will be free from degradation.

This interview was first published in the August edition of pv magazine global.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.