Scientists at the Martin Luther University Halle Wittenberg have investigated a new process for perovskite cell production, which they say could allow for creation of perovskite thin film layers with better long-term stability than others have achieved.

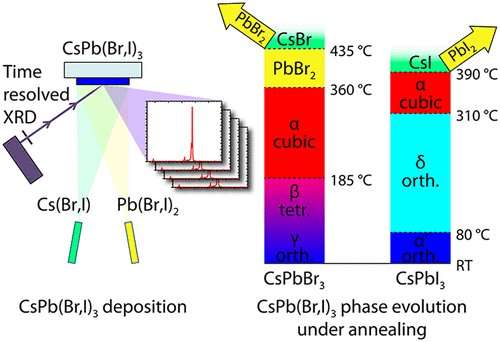

The process, co-evaporation, is already widely used in other industries. It is well established in some manufacturer and production equipment supplier processes for CIGS thin film PV deposition. It consists of heating precursor materials in a vacuum, until they evaporate, and then growing a layer of crystals onto a colder glass substrate.

“The advantage of this method is that every part of the process can be very well controlled,” explains lead author of the study Paul Pistor. “This way, the layers grow very homogeneously, and the thickness and composition of the crystals can be easily adjusted.”

The process described in the paper Crystal Phases and Thermal Stability of Co-evaporate CsPbX3 (X=I, Br) Thin films, published in the journal of Physical Chemistry Letters. The team was able to produce perovskite layers which did not decay until reaching a temperature of 360°C. Using x-ray analysis, the team also observed the growth and decay processes in real time.

Perovksites have been an important area of research in solar for the past several years, with research institutes and companies working hard to overcome weaknesses in the material that prevent its commercial use. The researchers in this paper say that they were able to gain important insights into this growth and decay through their observations, and that their research points to a process which could be applied to large-scale manufacturing.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.