Weekend Read: Predicting the solar future

The International Technology Roadmap for Photovoltaics (ITRPV) helps to predict future solar cell and module technology trends and is influential in directing research funding and technology investment. Scientists in Australia and the United Kingdom have analyzed ITRPV predictions over the past decade, highlighting the difficulties of forecasting PV trends.

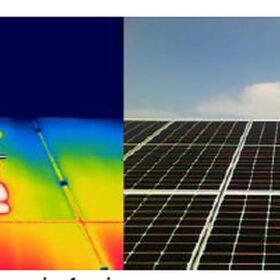

Combination of half-cut, bifacial solar cell designs may contribute to hotspot formation

Scientists in Spain tested PV modules under partial shading conditions, aiming to better understand the formation of performance-damaging hotspots. The study reveals a potential issue particularly affecting half-cell and bifacial modules, which may cause accelerated performance loss and is not covered by current testing/certification standards.

Greenpeace notes widespread greenwashing among fossil fuel companies

A new report published by environmental campaign group Greenpeace analyses financial statements from 12 major European headquartered oil companies. The study finds that, despite many public claims to be participating the energy transition, both the current activities and future investment plans of these companies are dominated by fossil fuels.

TOPCon PV modules outperform PERC by more than 5% in energy yield tests

A study by TÜV Nord in Malaysia shows that the latest generation of tunnel oxide passivated contact (TOPCon) modules surpass their older rivals on energy yield. The researchers compared n-type TOPCon modules with older p-type PERC modules, both manufactured by JinkoSolar over a three-month period earlier this year. The newer product showed an energy yield 5.69% higher than its PERC counterpart.

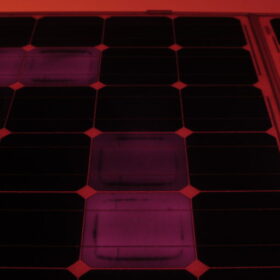

Thirty years of photovoltaic module degradation

Scientists in Europe have put together a comprehensive guide to PV module degradation, examining literature and case studies on the topic as far back as the 1990s. Their paper details the primary stress factors faced by modules in the field, the most common modes of degradation and failure, and provides clear definitions relevant to reliability, quality and testing standards. Among their key findings is that a full understanding of how combinations of different stresses over varying timeframes is still missing from methods to estimate and improve system reliability.

Inside the impacts of soiling

Scientists in India carried out a comprehensive study into the impacts of soiling on PV modules – measuring the amount of performance loss caused by different types of dust and bird droppings, and for modules installed at various tilt angles, in the hot-dry climate of Vellore in southern India. Their findings could allow developers to better take into account and mitigate the effects of soiling during site selection and system design.

Weekend read: the cells of the future

The annual SiliconPV Conference came to TU Delft in the Netherlands in April, and offered an important health check for the science and technology behind solar energy. pv magazine was on site to hear the latest from researchers reaching for higher efficiency through tandem cells and other innovations; looking to understand and mitigate cell degradation mechanisms; and working to cut down solar technology’s consumption of rare and expensive materials.

Weekend read: As simple as IBC

The search for ever higher conversion efficiency has driven solar researchers to focus on back-contact cell approaches, and efforts to devise more cost-effective manufacturing are bringing technologies such as interdigitated back contact (IBC) solar into the mainstream, as Mark Hutchins reports.

PV Expo 2023: Japanese solar’s struggle for space

PV Expo and the wider Smart Energy Week wrapped up in Tokyo last week. It revealed ambitious plans for solar and energy storage installations in Japan, including creative approaches to dealing with a severe lack of space for new installations, which should bring plenty of opportunities for domestic and international players.

Scratching the surface of silicon in tandem solar cells

German scientists have investigated the role of surface texturing in perovskite-silicon tandem cells and have found that several new processes offer the ability to etch smaller, more uniform textures onto the surface of a silicon cell than today’s industry standard. This could help to ease the subsequent growth of a perovskite cell on top of the silicon, enabling researchers and manufacturers to target higher performance.