From pv magazine Global.

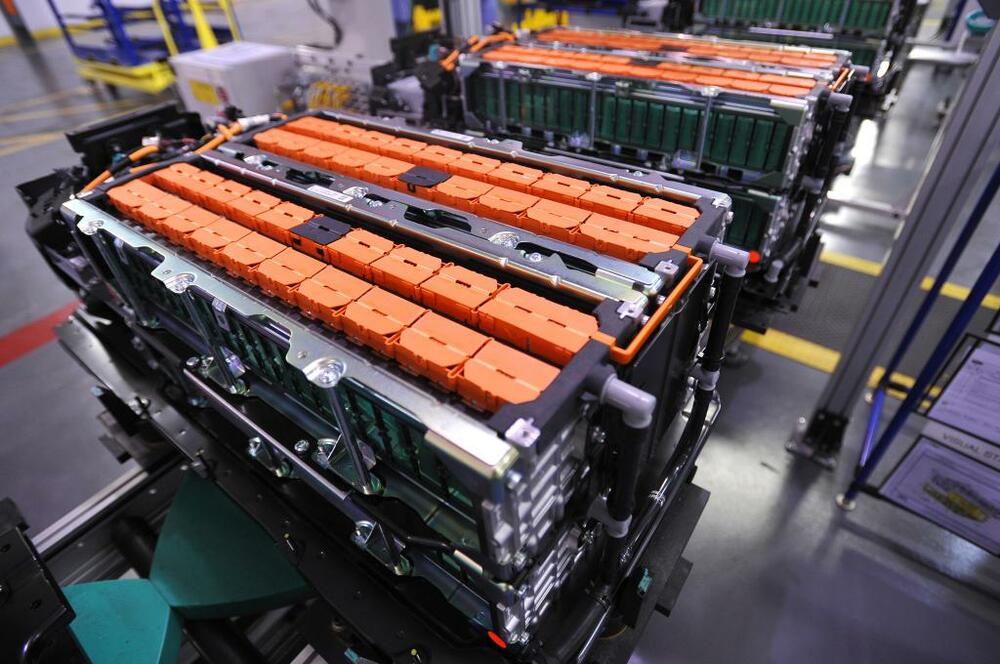

An international group of researchers has replaced graphite with a new compound as porous-negative-anode material in lithium-ion batteries for household appliances from smartphones to electric vehicles.

The novel material is composed of porous nanostructured microspheres made of copper, iron, and iron oxide with the formula Cu0.4Zn0.6Fe2O4.

The microspheres were synthesised through a one-step spray pyrolysis method, which is a technique used for temperature decomposition of organic material in the absence of oxygen. This process is known for providing excellent rate capability and high cycling stability and is used in the chemical industry to produce ethylene, carbon, and chemicals from petroleum, coal, and even wood, as well as to produce coke from coal.

An aqueous solution with ions of the special metals was converted into fog through an ultrasound technique and the water was evaporated at 1200 degrees Celsius, which decomposed the original metal salts. The process enabled the formation of micron or submicron spheres with the levels of porosity that are required for lithium-ion storage.

The new anode material is claimed to provide three times more capacity than current commercially available batteries and increase the number of charge-discharge cycles by five times compared to other promising alternatives to graphite. “This improvement is achieved due to a synergistic effect with a combination of a special nanostructure and the composition of used elements,” said researcher Evgeny Kolesnikov.

“The synergistic effect among the different cations, as well as the nano-dimension coupled with a hollow interior and surface porosity of the electrode materials, not only facilitate li-ion and electron transportation kinetics but also accommodate large volume expansion,” the research team explained. No information was provided on the cost of the novel material and the manufacturing process.

The new material was presented in the study Hollow-structured Cu0.4Zn0.6Fe2O4 as a novel negative electrode material for high-performance lithium-ion batteries, published in the Journal of Alloys and Compounds. The members of the research team came from Russia’s National University of Science and Technology (NUST), the Seoul National University of Science and Technology in Korea, India’s SRM Institute of Science and Technology, and the Norwegian University of Science and Technology (NTNU).

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

What company is making this nanomaterial ? and what is the stock symbol

Hi Billy,

Thanks for your question. The members of the research team came from Russia’s National University of Science and Technology (NUST), the Seoul National University of Science and Technology in Korea, India’s SRM Institute of Science and Technology, and the Norwegian University of Science and Technology (NTNU).