Alpha HPA announced it is progressing with stage two of its high-purity alumina refinery in the Queensland port city of Gladstone on the back of positive definitive feasibility study results and locking in $520 million (USD 348.7 million) in debt and equity project financing.

The company’s stage one precursor production facility, which features Alpha’s proprietary solvent extraction and refining technology to produce a range of high-purity alumina products for sale into the lithium-ion battery and LED battery markets, is already producing 99.99% pure aluminium products in commercial quantities.

Alpha Managing Director Rimas Kairaitis said the company has now reached financial close on the next stage of the facility and will immediately commence project execution for the full-scale facility, having already advanced several key elements of the project’s implementation.

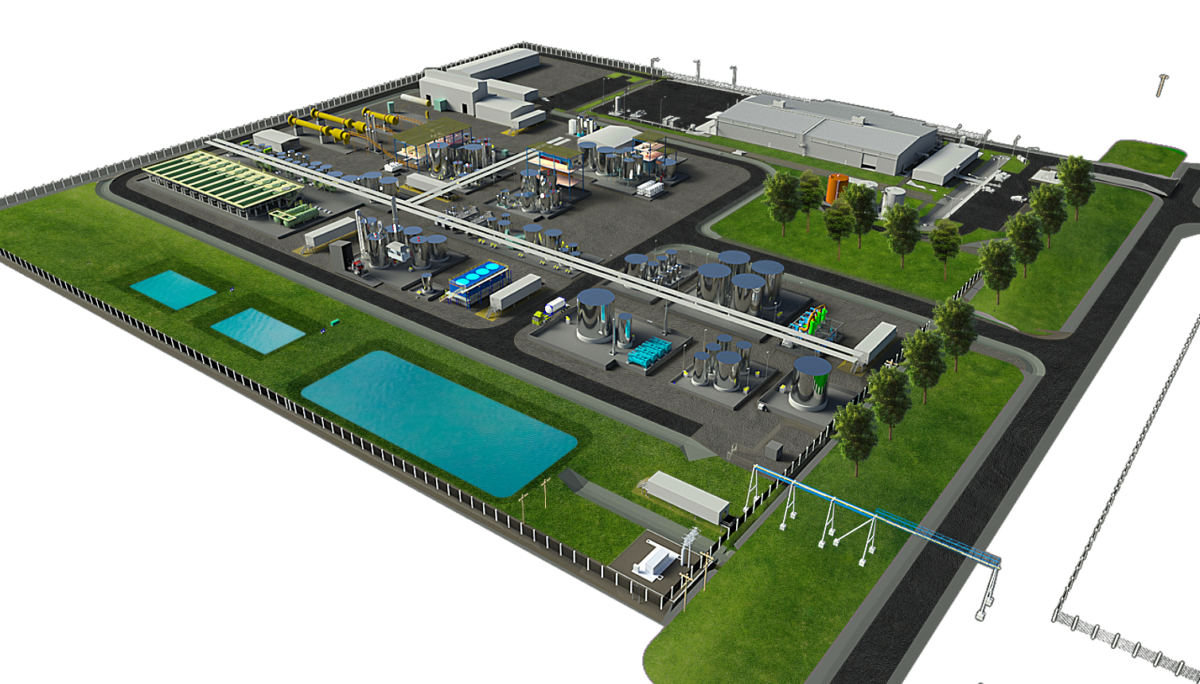

“Construction of the 10-hectare, state-of-the-art, full-scale facility will commence mid-2024,” Kairaitis said, adding that the second stage will encompass full-scale production of up to 10,000 tonnes of high-purity aluminium materials per year.

Alpha has secured credit approval for $320 million in project debt and an $80 million cost overrun facility from the Australian government’s Northern Australia Infrastructure Facility and Export Finance Australia. The company is also undertaking a fully underwritten $120 million institutional placement and non-underwritten share purchase plan.

Kairaitis said the positive feasibility study and project financing represent a comprehensive endorsement of Alpha’s technology and business strategy and allows it to establish “Australia’s first, large-scale commercial capability to manufacture high purity aluminas and related products to support key high technology growth sectors and the global energy transition.’’

Alpha said its process technology allows for the extraction and purification of aluminium from industrial feedstock, producing materials of exceptional purity for high-technology applications, including the semiconductor, lithium-ion battery and LED lighting sectors.

The project is expected to generate 120 ongoing jobs on top of 300 jobs during construction.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.