PV module designs tailored to specific climates are becoming more common. This development is underpinned by the knowledge that not all components in a bill of materials (BOM) can withstand every climatic condition.

Despite that general understanding, it is quite difficult to find reports that investigate the same type of PV modules exposed to different climatic conditions, exploring the effect on performance and durability. A recently published study investigated how different climates affect the durability and performance of panels, showing how the “one module fits all climates” approach does not really work.

We often think of photovoltaic modules as sturdy, long-lasting devices. While they are indeed built to withstand the elements, factors such as temperature, humidity, and ultraviolet (UV) radiation play a critical role in how quickly the power output from a PV module will decrease. Each material in a module has different susceptibility to those stressors.

Climate impact

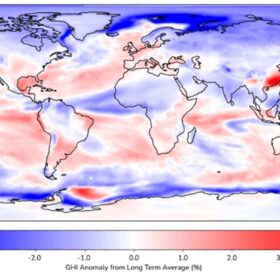

A team from Austria’s Polymer Competence Center Leoben (PCCL) analyzed this issue in depth, comparing the performance of photovoltaic modules in two very different climates. The researchers looked at modules with identical BOMs but exposed to the extremes of a tropical climate, with high humidity and temperatures, versus more moderate, temperate conditions.

The modules were designed using the same components, including ethylene-vinyl acetate (EVA) as encapsulant, crystalline silicon solar cells based on passivated emitter rear cell technology, and a fluorine-free polymer backsheet. The encapsulant plays an essential role in protecting the cells from moisture and external damage. However, over time, exposure to environmental stress can cause the encapsulant to degrade, ultimately affecting module performance.

The team studied four PV modules installed in different conditions for eight years. One of the modules was kept in a controlled environment as a reference product, while the others were exposed to the outdoors in the two different climates: one mild, the moderate climate, and the other extreme, the tropical climate.

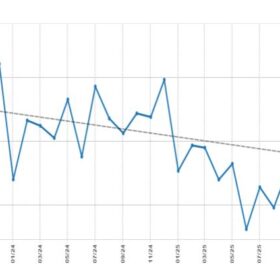

The PV modules installed in the tropical climate (TR1 and TR2) experienced significant performance loss. One of the modules (TR1) lost nearly 45% of its power, while the other (TR2) saw a more moderate 10% drop. That degradation was primarily due to corrosion of metallic components inside the panels, causing a significant decrease in fill factor. Electroluminescence imaging revealed the effect of corrosion on the solar cells. A reduction in short circuit current could be detected as well.

Photo: PCCL

By contrast, the module in the moderate climate showed little-to-no degradation. The power output remained mostly stable and the chemical composition of the EVA encapsulant did not show significant changes. While the moderate climate did cause some mechanical stress, due to temperature shifts between day and night, it did not lead to the same level of material degradation as seen in the tropical conditions.

Encapsulant degradation

The tropical climate’s combination of high temperatures, intense UV radiation, and high humidity created the perfect conditions for accelerated chemical reactions within the modules. Acetic acid – a byproduct of the breakdown of the EVA encapsulant – was found to be largely responsible for the corrosion of cells and metallic components within the modules. High humidity and heat levels in tropical environments led to a significant increase in acetic acid production, which severely damaged the solar cells.

One of the most important results of the study was the role of stabilisers and additives in protecting the EVA material. These substances, which are added to the encapsulant, help prevent the material from degrading too quickly under UV radiation and heat.

In the modules installed in the tropical climate, the stabilisers were quickly consumed by the extreme conditions. In fact, the UV absorbers and antioxidants designed to protect the encapsulant were almost completely gone after eight years of exposure. That depletion of material-stabilising additives led to photo-oxidation of the EVA, with a significant increase in acetic acid as a result. This eventually damaged the solar cells.

The results showed that the modules installed in the tropical climate had up to 10 times more acetic acid than the reference module, confirming the harshness of the climate on PV modules. The study also found that among all the characterization methods used to assess encapsulant degradation, differential scanning calorimetry was successful in detecting molar mass reduction of the EVA associated with deacetylation – namely, production of acetic acid.

The performance of PV modules is heavily influenced by the climate in which they operate. For regions with tropical climates or other harsh conditions, it is clear extra care needs to be taken when selecting materials to withstand those stresses. Panels in moderate climates may require fewer modifications, but those in tropical or desert regions will need designs that account for extreme heat, humidity, and UV radiation.

The full findings were published in January 2025 in the paper “Effect of Encapsulant Degradation on Photovoltaic Modules Performances Installed in Different Climates.” It appeared in the IEEE Journal of Photovoltaics.

About the author: Chiara Barretta is a researcher in PCCL’s sustainable polymer solutions division in Leoben, Austria, focusing on polymer encapsulants and backsheets used in PV. Barretta received her Ph.D. in material science and testing of polymer from the University of Leoben in 2023. Her work includes developing destructive and non-destructive characterization methods to describe polymer degradation in PV modules. She also focuses on understanding degradation mechanisms of PV materials under artificial and real environmental aging conditions, and optimizing processing conditions, such as lamination, based on product BOMs.

About the author: Chiara Barretta is a researcher in PCCL’s sustainable polymer solutions division in Leoben, Austria, focusing on polymer encapsulants and backsheets used in PV. Barretta received her Ph.D. in material science and testing of polymer from the University of Leoben in 2023. Her work includes developing destructive and non-destructive characterization methods to describe polymer degradation in PV modules. She also focuses on understanding degradation mechanisms of PV materials under artificial and real environmental aging conditions, and optimizing processing conditions, such as lamination, based on product BOMs.

The views and opinions expressed in this article are the author’s own, and do not necessarily reflect those held by pv magazine.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.