But high-profile incidents continue to occur in large-scale, high-hazard industries. Incidents like California’s recent Moss Landing battery fire, which destroyed roughly 80% of the facility and burned for days, raise significant safety and operational concerns. Lithium-ion battery fires are near-impossible to extinguish, making a robust safety and mitigation strategy essential.

While the benefits of BESS are significant, mining companies should proactively manage key risks to ensure reliable, safe operations. FM’s comprehensive research identifies six essential risk mitigation strategies for lithium-ion BESS in mining, which drastically reduce the likelihood and severity of incidents.

Strategic placement

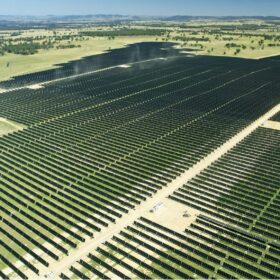

Positioning battery storage systems outside and away from critical infrastructure, high-risk areas, and densely populated locations is crucial. Operators should carefully assess the layout of the deployment sites to reduce the risk of fire spreading to essential equipment or personnel areas, protecting workers and minimising potential downtime.

The use of non-combustible enclosures

Constructing battery enclosures using fire-resistant materials helps contain fires and limit their potential spread. Non-combustible materials like concrete, steel, and brick can withstand high temperatures, provide valuable additional response time, and prevent collateral damage.

Separation and ventilation

Adequate spacing between battery units is vital to prevent the rapid spread of fires and explosions, as thermal runaway often leads to a chain reaction that impacts multiple units. Installing robust ventilation systems further reduces the risk by maintaining optimal temperatures and dispersing potentially hazardous gases, lowering the likelihood of fire ignition and propagation.

Fire protection systems

While it’s nearly impossible to extinguish lithium-ion battery fires, dedicated fire suppression systems, such as automatic sprinkler systems, are essential to temper the intensity of fires. This is particularly crucial when batteries are in buildings. FM’s extensive research and testing have shown sprinkler systems help control and limit fire events, preventing escalation into major incidents and reducing potential property damage.

Emergency response and redundancy

Mining operations, often situated in remote areas, must develop clear and actionable emergency response plans that reflect local firefighting capacities. Establishing backup power and redundancy systems ensures critical operations can continue even during a battery-related incident, minimising downtime and ensuring overall business continuity.

Ongoing maintenance and upgrades

Regular inspections, proactive maintenance, and continuous adoption of emerging battery technologies and improved safety standards help operators prevent incidents. By actively monitoring system health, identifying issues early, and upgrading equipment, mining companies can mitigate risks and adapt swiftly to evolving industry standards and safety protocols.

Deploying BESS with confidence

Adopting lithium-ion BESS offers substantial benefits, helping mining operators significantly reduce costs, emissions, and reliance on diesel generators. Yet, the inherent risks posed by battery fires and thermal runaway events demand rigorous and proactive management strategies.

FM’s six key mitigation strategies help mining operators take full advantage of these advanced systems, ensuring safe, sustainable, and reliable energy production for mining sites. But they represent just some of many considerations for safe and effective deployment.

Every operator and site face different challenges, requiring strategies that address specific needs with data-driven insight and industry best practices. This helps operators deploy lithium-ion BESS with confidence, protecting operational continuity, reducing costs, and improving environmental sustainability.

Author: Mike Hunneyball, Operations Chief Engineer, FM

The views and opinions expressed in this article are the author’s own, and do not necessarily reflect those held by pv magazine.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.