A group of researchers led by China’s Soochow University has developed a reliable perovskite indoor PV (PIPV) for self-powered devices.

The team has developed a small area test cell on which they conducted experiments, along with a mini module and an electronic price tag powered by the technology.

“The rise of the internet of things (IoT) has spurred rapid growth in demand for self-powered devices, driving the advancement of highly compatible indoor photovoltaics (IPV),” the group said in a press release.

“PIPVs have attracted significant attention due to their tuneable bandgap and high open-circuit voltage. However, long-term stability remains the most critical barrier to the commercialisation of PIPV and is currently under intense market scrutiny.”

To address the stability challenges, the group has included a hybrid-interlocked self-assembled monolayer (SAM) in the structure of the device.

That monolayer included a mixture of [ 4-(7H- dibenzo[c,g]carbazol-7-y l)buty l] phosphonic acid (4PADCB), with [4-(7H-dibenzo [c,g]carbazol-7-yl)ethyl] phosphonic acid (2PADCB). The 2PADCB:4PADCB mixture had a ratio of 1:1.

With varying carbon chain lengths, it effectively increased surface coverage on indium tin oxide (ITO) and enhanced the binding energy between the SAM and ITO.

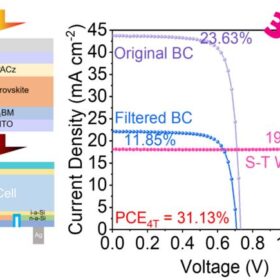

The fabricated cell and mini-module had ITO as the front electrode, 2PADCB:4PADCB as a SAM coating for the ITO, perovskite as the light-absorbing layer, PCBM as an electron transport layer, bathocuproine (BCP) as a buffer, and silver (Ag) as the back electrode. Overall, it had a cell structure of ITO/SAM/Perovskite/PCBM/BCP/Ag.

“The ITO-coated glass substrates underwent a cleaning protocol involving detergent and 15-minute rinses in deionised water, acetone, and ethanol. After being dried in an oven for over 3 hours, they were treated with ultraviolet ozone for 20 minutes,” explained the group.

“The SAM layer was deposited by spin-coating at 3000 rpm for 40 seconds and then annealed at 100 C for 10 minutes. Perovskite films were fabricated through a two-step spin-coating process, conducted at 1000 rpm for 10 seconds and 6000 rpm for 30 seconds.”

The mini module that was further developed using the same processes had a size of 5 cm ×5 cm. To facilitate the commercialisation of PIPVs, the academics developed an initial prototype of a self-powered electronic price tag, which used a yellow LED.

The prototype, cell, and mini module were all tested under indoor illumination, ranging from 200 lux to 2,000 lux.

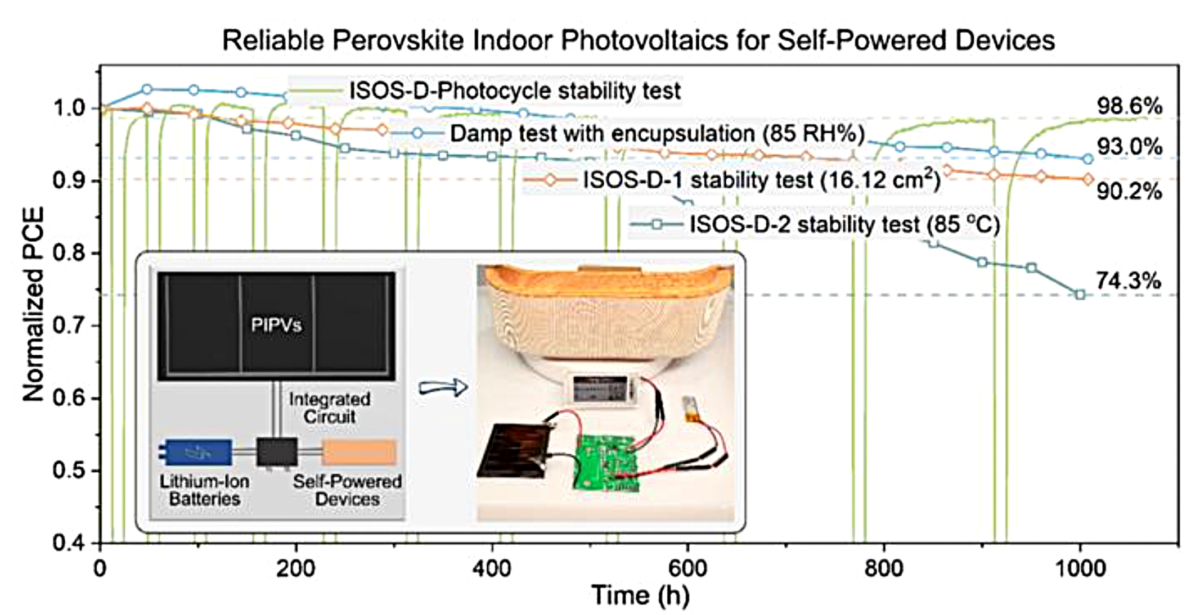

“The optimised devices achieved a record indoor power conversion efficiency (PCE) of 42.01% under 1,000 lux illumination,” the scientists concluded.

“Furthermore, during accelerated aging stability tests simulating diurnal-periodic light-intensity fluctuations from 2,000 lux to dark, the target devices exhibited a projected T90 lifetime approaching 6,000 hours. Ultimately, the PIPV module was successfully demonstrated to continuously and reliably power an electronic price tag via an integrated circuit.”

The cell was presented in “Reliable perovskite indoor photovoltaics for self-powered devices,” published in the National Science Review. The team also comprised scientists from Turkey’s Marmara University.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.