Researchers from Japanese and Spanish universities have developed an eco-friendly novel method to recover Polytetrafluoroethylene (PTFE), also called Teflon, which is used in solar panel manufacturing because of its ability to protect exterior components from environmental conditions, and extreme temperatures.

PTFE can be found in wafer carriers, pantograph joints (in space-based solar arrays), double diaphram pumps for handling powdered silicon carbide (silicon slurry) and coated fabrics and belts used as release sheets for the solar panel lamination process.

It can also be found in photovoltaic cells, where PTFE thin film cells can be manufacturered using low-cost glass, plastic, cermaics, graphite, metal sheets and other materials as substrates, and battery management systems, where a PTFE fibrillation process is used for lithium-ion batteries, and, for electric and fibre optic cable coatings.

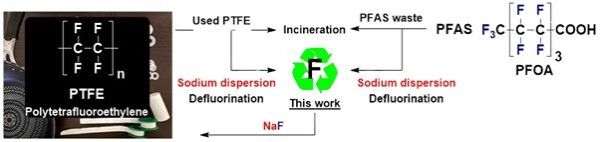

PTFE offers thermal stability, high durability and low friction but is typically disposed of via incineration, releasing highly corrosive hydrogen fluoride, or landfilling which leads to an environmental risks of undegraded PTFE. Traditional defluorination also requires high-energy, high-temperature reactions of between 100 to 500 degrees Celcius.

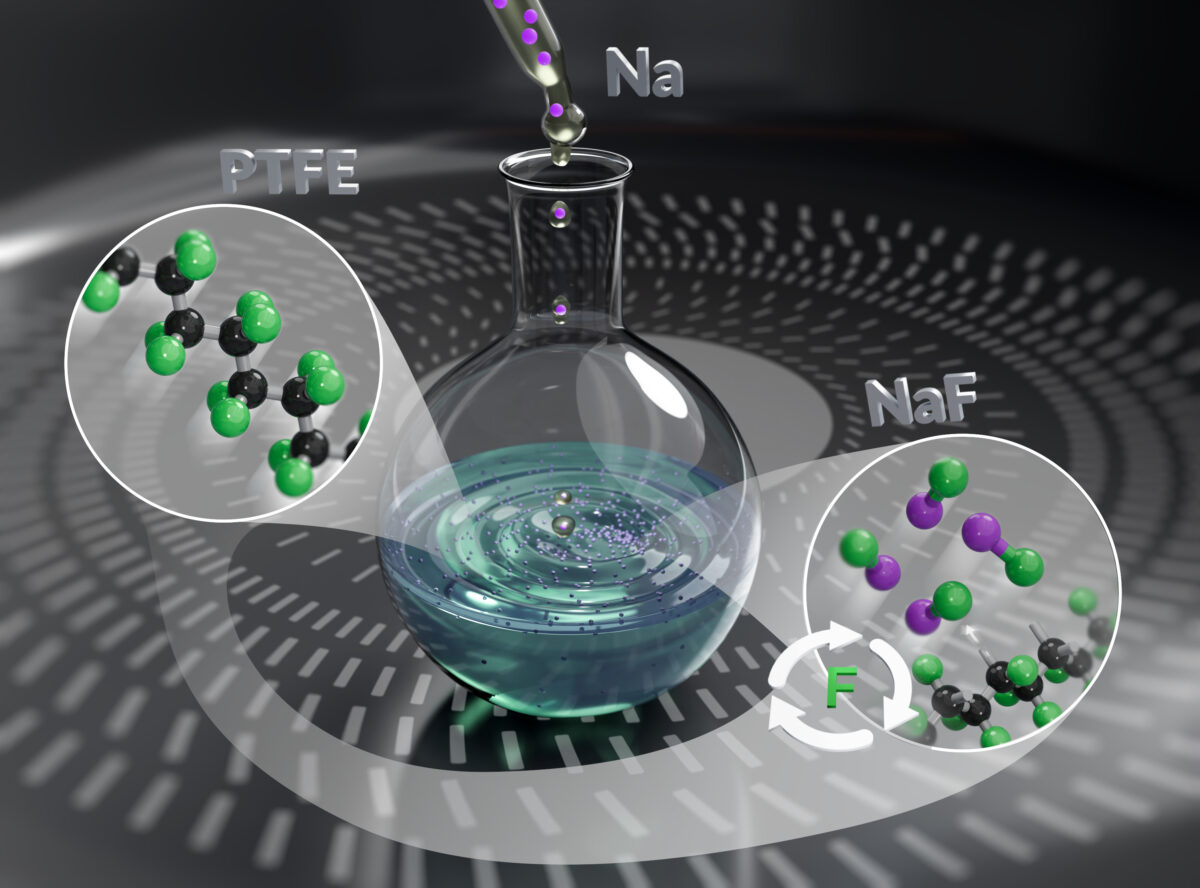

To address the gap of fluorine recovery inefficiencies, the researchers, led by Nagoya Institute of Technology (NiTech) Japan Professor Shibata Norio, developed a novel defluorination method that uses sodium dispersion to degrade PTFE and recover fluoride ion under mild conditions.

Image: Nagoya Institute of Technology

A statement by the researchers says of the new method, that a fluoride ion yield (in the form of sodium fluoride) of up to 98% was achieved from PTFE using sodium dispersion (2 equivalents) in tetrahydrofuran (THF) at a reaction temperature of 25 °C and a reaction duration of 12 hours.

“The major advantage of this defluorination approach is that it can operate at room temperature, avoiding the need for extreme conditions. To further verify fluoride recovery, the team examined the elements in the black residue obtained after PTFE degradation under optimised conditions using spectral analysis and estimated that the proportion of fluoride lost from PTFE was 93.5%,” the researchers said.

“Further analysis of this residue using X-ray diffraction, Raman and infrared spectroscopy, and nuclear magnetic resonance confirmed efficient fluoride recovery from PTFE.”

The method was also found to efficiently recover fluorine (up to 97%) from per- and polyfluoroalkyl substances (PFAS), namely perfluorononanoic acid, perfluorooctanoic acid, perfluorobutanesulfonic acid, and trifluoroacetic acid, once the reaction duration and sodium dispersion quantity were properly fine-tuned.

PFAS is found in some solar cells, particularly in coatings like anti-reflective and self-cleaning films, and in backsheets to increase durability and performance.

“In addition to PTFE, other fluorine-containing compounds are major environmental pollutants. Our defluorination method could effectively degrade PFAS, indicating its broad applicability,” Shibata said.

Despite their utility, PTFE and PFAS, pose major environmental concerns in relation to their effective degradation.

“In contrast to the conventional PFAS defluorination methods that require plasma processing or incineration at elevated temperatures, our defluorination method is an eco-friendly, non-energy-intensive approach with reduced toxic gas emissions that not only improves fluorine resource utilisation but can help minimize our dependence on fluorite in the future,” concluded Shibata.

The research, Room-temperature defluorination of PTFE and PFAS via sodium dispersion, has been published in the journal Nature Communications.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.