Researchers from the University of New South Wales (UNSW) have sought to improve TOPCon solar cell efficiency by reducing the thickness of the polysilicon (poly-Si) layers used in these PV devices to improve passivation and carrier transport.

In the paper “Mitigating parasitic optical losses in bifacial TOPCon solar cells through localised thinning of polysilicon,” published in Solar Energy Materials and Solar Cells, the team explained that parasitic optical loss in the poly-Si layer is a key limitation for TOPCon cells. Long-wavelength photons can reach the back side of the cell and bounce around, entering the poly-Si layer where some energy is lost as heat instead of generating electricity.

Previous studies have shown that thinning the poly-Si layer can reduce parasitic absorption. However, excessive thinning increases recombination losses due to metal paste reaching the wafer. To address this, the UNSW researchers used a laser-induced local thinning method to reduce the poly-Si layer in non-metalized areas while keeping its thickness intact in metallised regions.

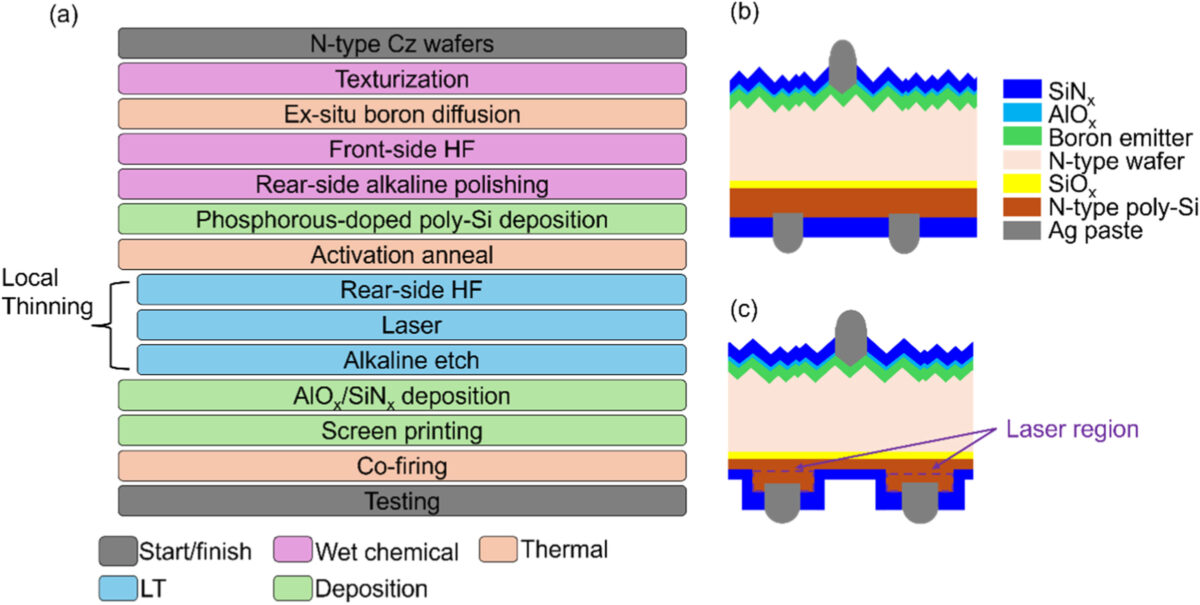

The team implemented a three-step local thinning process integrated into the standard TOPCon fabrication flow to produce low-temperature TOPCon (LT-TOPCon) devices. A 1.3 nm interfacial oxide layer was deposited via plasma oxidation in a physical vapor deposition (PVD) chamber, followed by deposition of a 110 nm poly-Si layer at 250 C. Dopant activation was achieved through annealing at 860 C for 50 minutes. A 355 nm UV picosecond laser was used to induce amorphisation in selected regions of the poly-Si layer.

“Following the laser step, the wafers were etched in a 0.1 wt% sodium hydroxide (NaOH) solution at 40 °C to reduce the poly-Si thickness in the non-lasered regions to approximately 30 nm. Subsequently, an aluminum oxide (AlOx) layer was deposited on the front side, and silicon nitride (SiNx) layers were applied to both sides. The precursors were annealed in the same PECVD chamber to activate the passivation from the rear SiNx and front AlOx/SiNx stack,” the researchers said.

The team also used Quokka 3, a simulation tool for silicon solar cells, to evaluate the short-circuit current and overall efficiency of the new devices.

The champion LT-TOPCon cell achieved a power conversion efficiency of 25.10%, representing a 0.12% absolute improvement over a 24.98%-efficient reference cell fabricated without the new process. The cell also reached a fill factor of 83.37%, slightly below the reference’s 83.45%, while the open-circuit voltage increased marginally from 727.9 mV to 729.8 mV.

“This indicates that the LT process preserves or even enhances surface passivation despite the poly-Si thinning,” the team noted.

Additionally, the cell demonstrated a 6.6% improvement in bifaciality, and the researchers anticipate a further 0.35% absolute efficiency gain through optimised laser-induced doping, improved process uniformity, and advanced metallisation schemes.

“The proposed process is designed to be compatible with existing TOPCon manufacturing flows and relies on industry-relevant steps such as laser processing and wet chemical etching, making it promising from a process integration perspective,” Song said.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.