From pv magazine Global

An international research team has investigated how mechanised farming could be combined with agrivoltaics and has found the key for succes is a holistic, farm-specific co-design process.

“Our research addresses the integration of agricultural mechanisation into agrivoltaic system design,” the research’s lead author, Yuri Bellone, told pv magazine.

“It highlights how early planning for machinery maneuverability is necessary to prevent the loss of cultivable land and ensure the economic viability of the agricultural component within agrivoltaic projects.”

“We examined the often-underestimated challenge of developing agrivoltaic systems where agricultural mechanisation is an essential requirement,” he went on to say.

“This underestimation of designing a proper mechanisation strategy may results in insufficient available space, hindering machinery maneuverability and leading to a significant loss of cultivable land. When land cannot be processed effectively with standard machinery, specifically for tasks such as soil tillage and crop harvesting, the profitability of the agricultural activity within the agrivoltaic system is negatively impacted.”

In the study “Agricultural mechanisation in agrivoltaic systems: Challenges, adaptation, and possible advancements,” published in Renewable and Sustainable Energy Reviews, the scientists outlined the specific considerations required prior to designing an agrivoltaic plant to ensure the continuity of agricultural activity.

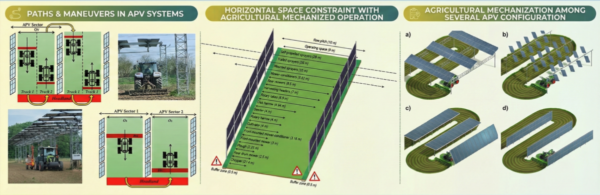

“While agrivoltaics systems aim to increase agricultural sustainability both economically and environmentally, the physical arrays divide land into sectors inscribed within PV rows. Each sector acts as an independent unit defined by the specific agrivoltaic typology, with varying spatial constraints,” Bellone further explained.

“Consequently, the horizontal length, intended as the available space for planting and tillage, and vertical clearance, within each sector becomes a primary design factor. A significant barrier is that agricultural machinery and implements are highly variable and typically designed for open-field agriculture rather than the constrained pathways generated in agrivoltaics.”

To address this, farmers must plan the mechanisation fleet in alignment with the entire crop rotation intended for the specific farm.

“This planning is complicated when relying on third-party contractors, who may utilise machinery not perfectly suited for maximum efficiency within each specific agrivoltaic plant,” Bellone emphasised.

“However, the research notes exceptions, such as machinery designed for viticulture and trellis systems, which hold potential for adaptation within denser agrivoltaic patterns.”

The researchers also noted that, when widely spaced PV arrays are used, buffer zones alone can cause up to 30% land loss. Moreover, they emphasised that, under agrivoltaic systems, mechanised field operations are also less efficient, with efficiency potentially falling to about 45% due to slower working speeds and poor alignment between machinery width and available space.

They also recommended aligning machinery pathways with the PV system layout rather than the field’s natural orientation.

“There is no universal solution that fits all possible agrivoltaic configurations and the optimal strategy for mechanising agriculture in agrivoltaics depends on a nuanced interplay of PV, farm scale, crop selection, available machinery, third party contractors’ availability for mechanised operations and company investment capacity,” they emphasised.

The group also explained that standardisation is currently difficult to achieve given the vast heterogeneity in agricultural machinery, noting that project design may also have an impact on fuel consumption and operational costs of the machinery involved.

For example, fuel use could rise because of operational inefficiencies, including increased overlap and more frequent turning, as narrower implements are often preferred in agrivoltaic systems compared with open fields.

Looking forward, the scientists intend to discover pathways to improve the operational efficiency and energy consumptions of agricultural machineries within agrivoltaic systems.

“Advancements in precision agriculture technologies, including GPS-guided machinery and optimised route planning software, hold considerable promise for mitigating the discussed operational constraints,” they concluded.

The research team comprised academics from Mälardalen University in Sweden, as well as from Italy’s Catholic University of the Sacred Heart and the Council for Agricultural Research and Economics (CREA).

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.