Is Australia Crawling toward electric ferries?

Last year the New South Wales Government announced plans to retire several of the iconic Manly ferries and replace them with smaller vessels. However, the recent launch of the world’s largest electric ferry in Norway has one Aussie billionaire asking whether the new Manly ferries should be electric?

WA start-up prepares to be one of the world’s first Li-ion battery anode producers outside China

With reins tightly held by China, a handful of players are trying to prise the production of a core ingredient of lithium-ion batteries out of Goliath’s hand before the battery boom begins in earnest with the electrification of the transport sector. The head of one of those companies, WA start-up International Graphite, spoke to pv magazine Australia about the hunger of both investors and customers, and the surprisingly collaborative race to feed global demand.

Angus Taylor launches $50 million carbon capture fund despite long road

As present affairs of state attest, sweeping things under the rug is the preferred strategy of the Morrison Government, and hence its $50 million investment in carbon capture and storage (CCS). According to a recently published report from IDTechEx, CCS faces a difficult few years and a long way to go. Unfortunately, even if he does reach its forecasted scale by 2040, its capacity to remove emissions from the atmosphere in any hurry is negligible.

Pumped hydro with desalination, powered by renewables

EDF and Oceanus plan to build a pumped hydro storage station and a desalination system powered by wind and solar. The system will use saltwater to produce hydropower during periods of high demand, while producing affordable freshwater.

Compressed green hydrogen ship for Aussie exports deemed ‘highly competitive’

A scoping study has found Global Energy Ventures’ compressed hydrogen ship to be both technically feasible and ‘highly competitive’ to transport the hyped future fuel at distances that conveniently connect Australia to Southeast Asian markets.

Novel nanomaterial to replace graphite in lithium-ion batteries

Porous nanostructured microspheres made of copper, iron, and iron oxide were used by an international research team as negative anode material in lithium-ion batteries. The new technique is claimed to provide three times more capacity than batteries based on graphite anodes.

Relectrify’s ReVolve rollout gives new life to EV batteries

Battery technology company Relectrify has turned its focus to the commercial and industrial (C&I) sector with the launch of a 36 kW / 120 kWh commercial-scale modular battery energy storage system (BESS) which utilises second-life electric vehicle (EV) battery packs.

Vehicle-integrated PV reduces EV charging time in sunny regions by 40%

Dutch scientist Bonna Newmann spoke with pv magazine about the present and future of vehicle-integrated PV from a technological and economic perspective. Solar panels installed on cars could have a payback time of only three or four years and ensure 10,000 km of pure PV-generated road travel per year, she said. Furthermore, if you live in a sunny place, you can drive an electric car with solar panels for weeks during summertime, without the need for recharging, she pointed out.

Bluescope says climate action is ‘not optional’, while opting not to take climate action

On the same day as Bluescope Steel announced massive profits and the creation of a new Chief Executive Climate Change, the steel giant also conceded that it was not fully committed to investing in ‘green steel’ solutions in the near future.

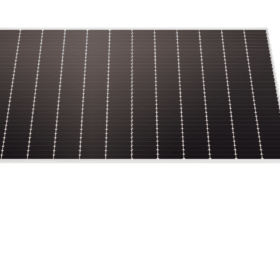

New shingled PERC solar module from Hyundai

The South Korean manufacturer has brought, to Europe and Australia, its recently launched shingled PERC panel, with an output ranging from 460 to 480 W and an efficiency of up to 20.5%. The products come with a 25-year linear power output guarantee and a 25-year product guarantee.