Meyer Burger unveils new solar tiles

Meyer Burger plans to start selling a new building-integrated PV product from 2022. It says the solar tiles have a high energy yield, with simplified installation and the ability to also provide heating. German engineering company paXos designed the tiles.

Electro-thermal storage system for commercial applications launched

Developed by Swedish manufacturer Azelio, the system stores renewable energy in recycled aluminium and has an electrical and thermal energy output, with a total efficiency of 90 %. One unit’s storage capacity reaches 165 kWh of electrical output and on top of that thermal energy between 55-65 degrees Celsius. Its modular configuration allows the deployment of projects with a capacity of up to 100 MW.

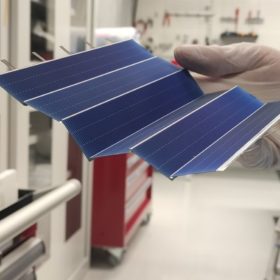

New ‘matrix’ layout for shingled solar cells

German equipment supplier M10 and research institute Fraunhofer ISE will unveil a new prototype stringer for shingled module layouts at the Intersolar Europe trade show later this week. Employing an offset layout for the shingles, the approach promises a relative efficiency gain of up to 6%, compared to a conventional half-cell module.

Solar tile with 14.2% efficiency from Denmark

Dansk Solenergi ApS has developed a 13.6 kg tile that can be used for both new buildings and building renovation. The device is currently being produced in Denmark, where the company operates a 40 MW line.

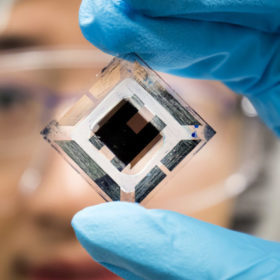

New discovery could make organic PV competitive with crystalline silicon

A group of international researchers has observed how non-radiative charge recombination occurs in organic PV and claims to have identified a potential solution that could bring this solar tech closer to crystalline silicon in terms of power conversion efficiency.

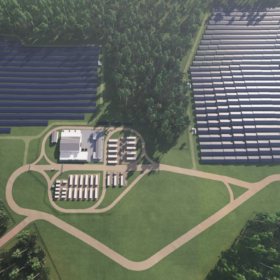

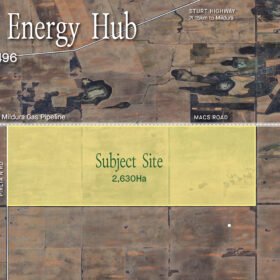

HDF to construct baseload power plant using green hydrogen, plans Australia expansion

The project includes a solar park coupled with what HDF Energy claims is the “largest green hydrogen storage of intermittent electricity sources” at 128 MWh. Importantly, the company also simultaneously announced expansion plans into Australia, saying its hydrogen technology will soon be available here, adding that it has “projects already in development for Australia”.

Solar-plus-hydrogen for air traffic control

A 19.8 kW PV system is powering a telecommunications antenna at a French air control centre. When it produces more energy than needed, the surplus is used to produce hydrogen which is then utilised to produce new electricity via a fuel cell system and provide power to the antenna during a period of up to five days. For short-term storage, lithium-ion batteries are used.

Sunday read: Price cannibalisation threatens PV growth

As solar deployment increases, concerns about price cannibalisation continue to be more and more relevant. Large-scale solar generation during midday hours may result in curtailment or unprofitable wholesale power prices. As supply increases, the economic viability of solar PV projects could fall into question.

Fraunhofer ISE develops solder-free aluminium interconnection tech for shingled PV modules

The German research institute has unveiled a novel interconnection technology for shingled PV modules that eliminates the need for electrically conductive adhesives and screen-printed busbars. It consists of an 8-μm-thick aluminium foil that is joined to the silicon nitride (SiNX) passivation via laser metal bond (LMB). When integrated in a solar module, the efficiency of the new interconnector improved by 0.7%.

Agrivoltaics for strip farming

Vattenfall is leading a Dutch consortium in a research project to assess whether agrivoltaics is also compatible with strip cropping. The company’s head of Solar Development NL, Annemarie Schouten, spoke with pv magazine about the first 0.7 MW pilot project under development in the northern Dutch province of Flevoland.