A closer look at liquid air energy storage

A British-Australian research team has assessed the potential of liquid air energy storage (LAES) for large scale application. The scientists estimate that these systems may currently be built at a cost between €300 and €600 (AU$480 to $960) per megawatt-hour and that a positive business case could be favoured by certain conditions, including a determined price structure in the energy market and the presence of a grid unable to support high levels of renewable energy penetration.

Sodium-ion batteries a commercial reality, claims CATL

The manufacturer has launched sodium-ion products online. Production has begun and will be easily scalable, according to the CATL chairman. Researchers have been keen to make the technology work as it offers a cheaper, more environmentally friendly alternative to lithium-ion products.

The trillions spent by G20 nations on fossil fuels from 2015 to 2019 could have paid for more than 4 TW of solar

Polluting energy sources received more than $3 trillion from the EU and 19 of the world’s largest national economies over that four-year period, despite G20 members having pledged to phase-out fossil fuel subsidy and address climate change back in 2009.

Solar manufacturers warn of 12-18 months disruption for standalone products

Potential price rises of 14% for the solar home systems that are driving access to electricity in the world’s under-served regions could signal further arrested progress towards the UN goal of universal access by 2030.

‘Polysilicon shortage will continue through 2021’

The latest global PV industry outlook published by trade group SolarPower Europe, has indicated tight supply of the solar panel raw material is expected to persist this year but the trade body said it would be unlikely to drive further price rises.

REC unveils second generation of its N-Peak solar module

The manufacturer plans to start production of the performance-enhanced solar modules in August. The first customers should then receive the products in October.

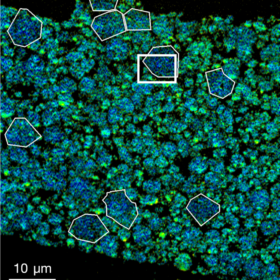

Hold your breath for a better battery

Recent research has revealed a previously underestimated role for oxygen in limiting the performance of lithium-ion batteries. Newly published research from both Japan and the United States has sought to look deeper into the chemical reactions at the heart of lithium-ion storage; and to better characterise the cumulative effects that minuscule amounts of oxygen released during these reactions can have on battery performance and safety.

Importers could pay EU carbon tax from 2026

European commissioner for economy Paolo Gentiloni has outlined how the commission’s planned revision of the energy taxation regime, and introduction of an EU carbon border, could be applied.

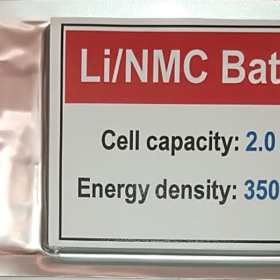

New battery chemistry tweak could double EV range

Researchers at the Pacific Northwest National Laboratory have developed a revolutionary lithium-metal battery chemistry that could allow electric vehicle batteries to almost double their capacity, while also overcoming historic setbacks.

Portable hydrogen fuel cell generator with power output of 400 W

The generator can be combined with batteries, solar panels, or small wind turbines. It is based on a proton exchange membrane fuel cell technology and is claimed to have a minimum lifetime of 5,000 working hours.