From pv magazine global

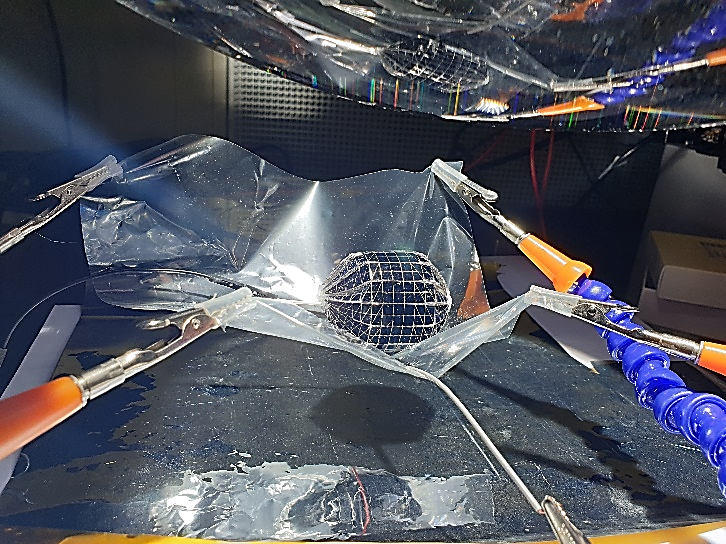

A group of scientists from Saudi Arabia’s King Abdullah University of Science and Technology (KAUST), the University of Jeddah, and the University of California, Berkeley, have demonstrated an interdigitated back contacts (IBC) spherical solar cell with stronger heat-dissipation and reduced dust accumulation compared to conventional flat solar cells.

The monocrystalline 3D device, which has a reported efficiency rate of 18.93%, is also said to have a 101% higher power yield compared to flat cells.

Cell architecture

The researchers describe their findings in Nature-inspired spherical silicon solar cell for three-dimensional light harvesting, improved dust and thermal management – recently published in MRS Communications – the new cells are able to track direct sunlight, exploit diffuse beams, and recycle background reflected light.

“Our design is inspired by the large spherical eyes of houseflies, which increase their angular field of view and enable them to see 270 degrees around them in the horizontal plane, in addition to sunflowers that track the sunlight during the day, all year,” the scientists explained.

Through a corrugation technique, the research group was able to develop a cell with 138 μm-wide grooves. This made it possible to achieve a flexible structure with total area loss of only 5.6%.

“As a result, islands are obtained that are readily interconnected by the IBC grid,” it added. Polydimethylsiloxane was spin-coated on the corrugated cell before encapsulation.

The solar cell was tested with a 1 Sun AM 1.5G solar simulator with different background reflective materials, with one based on aluminum exhibiting the best reflecting performance. This solution is the one ensuring the aforementioned 101% yield increase.

Thermal performance

The test has also showed that the spherical cell also provides 10% lower maximum temperature compared to flat cells, while power output is 9.6 % higher.

Under the same temperature coefficient, the spherical device has also an average temperature that is 31.6% lower than that of a flat cell, the academics claim.

“The result shows a large range of temperature distribution over the surface of the cell, where the area exposed with direct light, perpendicularly to its surface, heats up the most, while other regions that receive light rays with a nonzero angle of incidence, show a reduced temperature,” the group explained.

The measurements have also shown that the spherical cells accumulate less dust than flat cells.

“We believe that the presented results create new engineering opportunities for the well-established silicon solar cells industry in order to achieve a higher solar power output for the same ground area without having to move to the higher cost and higher efficiency materials and processes,” the scientists concluded.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.