Tomago, on the outskirts of burgeoning Newcastle and its world-class port, with its access to the skilled labour of the coal fields, the doctorates of Newcastle University, CSIRO’s Energy Centre research hub and supply chains of mineral wealth throughout Australia, has won the distinction and job opportunities inherent in becoming home to Energy Renaissance, Australia’s first advanced-manufacturing, lithium-ion battery facility. Dubbed Renaissance One, the facility will be the flagship of ER, which intends to ramp up production to 5.3 GWh per annum of safe, affordable, hot-climate-optimised batteries for Australia and South East Asian markets in coming years.

“The Hunter region has all the right skills, natural resources, expertise and an abundance of solar energy for us to develop a successful battery manufacturing business,” said Mark Chilcote, Energy Renaissance (ER) Managing Director — one of the company’s highly experienced business executives with a long-held dream to commercialise Australia’s innovations onshore.

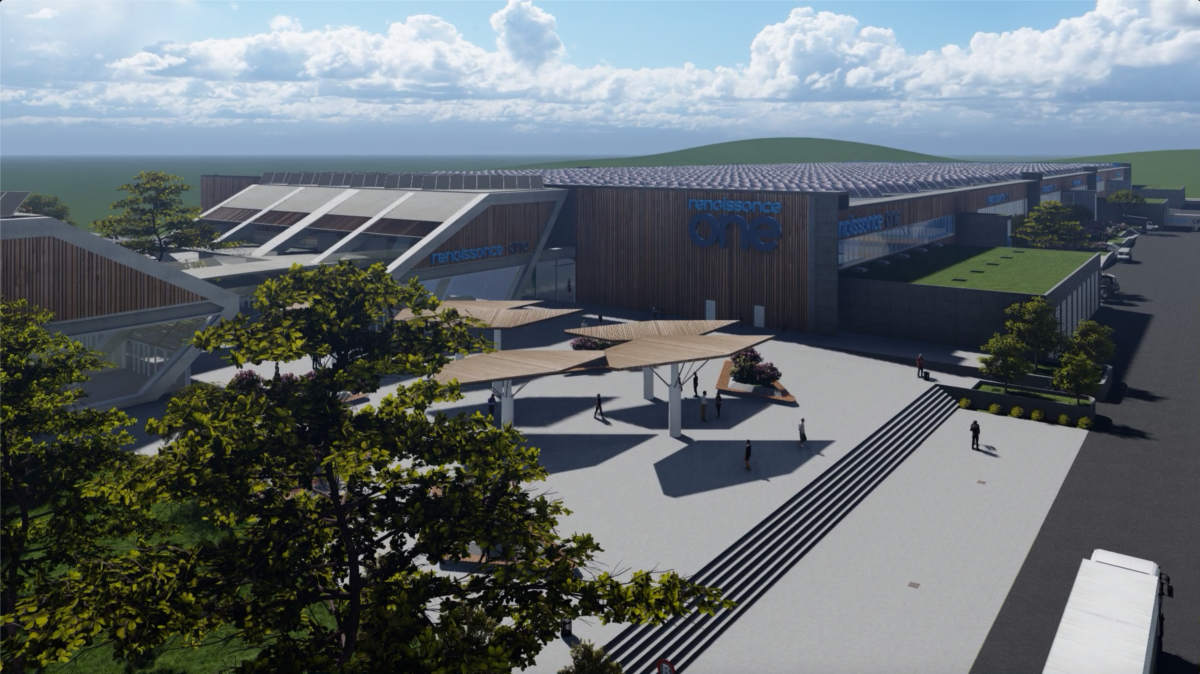

The site of the $28 million Renaissance One facility has been announced, after five years of developing a product that Chilcote and his colleagues envisage will contribute to reductions in global warming and help set the Australian economy on the path to clean-tech manufacture.

Today’s ceremony is ground breaking in many ways, marking as it does the start of ER serving the regional market for safe LiBs that it says operate extremely efficiently in hot-climates, using cell technology developed in partnership with Cadenza Innovation and the CSIRO, and incorporating Australian mined and refined lithium, lithium carbonate and battery-grade graphite.

New venture, new build, new opportunities

The automated production facility at Tomago will start construction almost immediately, and ER anticipates providing 1,700 new direct employment opportunities across the build phase and as the company ramps up to full production within eight to 10 years.

“We’re in discussions with the Federal Government to get some funding as part of the Budget, so that we can bring that forward,” thereby creating 1,242 permanent jobs, beyond the initial construction boost, over the coming three to five years, Chilcote tells pv magazine. He adds that the company’s research has shown that “Every job we create will be a catalyst for five jobs upstream in the supply chain,” in industries such as mining and mineral processing.

Australian property developer ATB Morton will build and own the site and infrastructure of the Tomago facility, leasing it to ER which plans to begin manufacturing at its new 4,000 square-metre, purpose-built base in mid 2021, and achieve commercial production of batteries that will be used to power homes, buildings, business and infrastructure by the end of next year.

Image: Energy Renaissance

The company is set up for initial production capacity of 66 MWh per annum, and expects to export more than half of its output through the Port of Newcastle.

Improving and greening the region’s access to electricity

An early partnership with Edison Projects Australia (EPA), which develops energy solutions for rural and remote communities, will see deployment of ER-battery-backed, solar-powered lighting and fridges in the Pacific Islands — enabling communities to travel and walk more safely at night and store perishables including essential medicines where they live.

“It’s not huge from a revenue perspective, but it’s great to see it happen,” says Chilcote of this initial collaboration with EPA. He adds that the reveal of Tomago as its chosen home, will now become the springboard for ER announcing other distributorships and partnerships currently under negotiation.

Overall, he says, the demand for battery storage currently “outstrips manufacturing capabilities”, and the ER offering will be cost competitive with “high-end Chinese, Korean and American product”. He adds, “Anyone can Google Alibaba and buy a battery cheaper than ours, but it’s at risk of catching on fire, and it will quickly degrade — there are markets for that kind of product, but we don’t want to compete there.”

Integrating SuperCells in modules that further defy heat

Cadenza battery cells have been developed to provide a low-cost solution to the flammable propensities of lithium-ion batteries, and to address the fact that most batteries expend 30% of their stored energy keeping themselves cool in order to continuously operate. ER has entered into a long-term licensing agreement with Cadenza Innovation to produce its so-called SuperCells in Australia.

On home soil, ER has worked with CSIRO, and recently with co-funding of $246,625 from the Advanced Manufacturing Growth Centre, to develop unique hot-climate-optimised battery modules — the cell housing — that can be scaled for numerous applications from battery packs suitable for installation at the base of a streetlight, to commercial-size and grid-supporting energy storage.

Solar-powered, advanced manufacturing

ER will demonstrate the utility of its systems and its energy integrity from the get go at Tomago: The buildings and car park of Renaissance One will be decked with 800 kW of solar PV, and their excess energy stored in ER batteries onsite. The additional electricity needs of this energy-thirsty facility will in the first instance be provided by GreenPower-accredited sources, but ultimately, Chilcote says, “We’ll enter into a PPA that enables someone to build a solar farm or a combination of solar and wind.”

Chilcote likens the robot-assisted manufacturing scene within ER’s high-tech factory to that of pharmaceutical production facilities, saying it will be all white coats and hairnets and highly filtered air, in order to maintain a virtually sterile environment that ensures no impurities enter the cells during manufacturing processes that adhere to stringent quality control.

He says the Energy Renaissance team is excited to enable truly advanced manufacturing, run by Australians, in their backyard, and looks forward to skilling local workforces.

Because the processes involved are new to the country, Chilcote tells pv magazine, “It’s going to be an exercise in skills transfer. Anyone currently operating a chemical plant or a gas plant could be reskilled,” for Renaissance One, and “There’ll be a lot of work for chemists and scientists, engineers, plenty of opportunities for graduates and interns,” he says.

Bringing researchers and production under one roof

Renaissance One is not all robots and production lines, but incorporates areas for researchers to advance LiB technology.

ER’s ever-evolving R&D partnership with CSIRO is currently working on refining the Battery Management System (BMS) that controls operation of ER batteries, to wring greater performance from the cells, while extending their lifecycle, and thereby extending ER’s competitive edge.

At the Renaissance One groundbreaking ceremony today, Patron Senator for the Hunter Region, Hollie Hughes congratulated ER on its vision and investment, and said, “Energy Renaissance will make clean and affordable energy more accessible and create greater energy security for Australia and our neighbouring countries.”

She gave some sense of the scale of the Tomago-based output, saying “Once Renaissance One is operating at capacity it will be able to provide — in the space of a year — enough batteries to power every public school, hospital, fire station, SES and new home built in Australia,” thereby enabling the country “to rely on its own sources of renewable energy in the very near future”.

Chilcote and his partners are living their dreams, which he says is both thrilling and nerve wracking, as today marks the start of the next phase of development activity in every aspect of the business, from recruitment, to sourcing of long-term local suppliers. Within three years, he says, the company intends its batteries to be 100% Australian — “a sovereign-supplied operation”, with the credentials to power organisations such as the Australian Defence Forces, and critical regional infrastructure.

Image: Energy Renaissance

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Just down the road from me so this is really interesting.

However, is there anywhere that describes in reasonable detail the cell chemistry and production techniques used? Will they be competitive with Tesla’s next-gen cells in cost? Because if they can’t, their home Powerwall is going to get crushed commercially. Also, what’s the specific energy (Wh/kg)? I’m thinking specifically of large mobile uses (trains).

This is absolutely wonderful! 🙂 Although I don’t believe they are the first company to do this in Aus, as PowerPlus Energy has been around for a few years manufacturing Australian made lithium-ion batteries. Still great to see funding going into this industry!

Hi Annie,

You’re absolutely right. I was recently in touch with PowerPlus Energy, which has until now flown a little under the radar. But they are on there now and I will absolutely be watching that space!