A new division of French energy giant Engie is quietly bringing strategy, engineering and software to bear on the decarbonisation targets of companies in Australia. Engie Impact, a sustainability consulting initiative with 2000 employees globally, has nine in Australia so far, led by Senior Director, Josh Martin.

“We want to be working with companies that face some really challenging decarbonisation problems, and help them find solutions,” the energy strategist told pv magazine Australia.

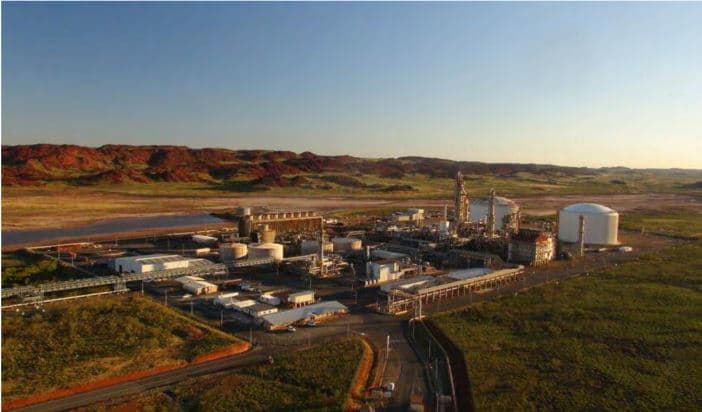

The recent successful application to ARENA by Yara Pilbara Fertilisers, for funding to test the feasibility of transitioning from natural gas-fed ammonia production to using green-hydrogen as a feedstock for synthesis of green ammonia, was assisted by the Engie Impact team.

“We essentially plotted a range of scenarios through which they could pursue their net-zero goal, and landed on one that had a positive business case for Yara,” says Martin.

The service is available to any company, and Martin says Engie Impact is unique among consultants in bridging the gap between intention and implementation.

Most companies fall off the net-zero wagon

Analysis of respondents to the not-for-profit CDP (formerly Carbon Disclosure Project), found that of all the companies that have declared their emissions-reductions goals, only 28% are on track to achieve them.

CDP, operates globally, and was set up in 2020 to make discussion and disclosure of company emissions and emissions challenges the norm. Over the past 20 years, more than 10,000 companies, cities and states have signed up to disclose their environmental risks and impacts.

“If we’re going to align and actually meet the targets of the Paris Agreement, we need everyone to play their part,” says Martin.

As part of its consultation process, Engie Impact deploys its Prosumer simulation tool, developed by Engie Labs, to identify the most cost-effective combination of investments a company can make in decarbonisation technologies — such as energy generation using solar and/or wind, battery energy storage, green hydrogen production and energy efficiency technologies — to accelerate its progress to an emissions-reduction goal.

Martin calls out an example of a more industry-specific technology, Elysis, currently being refined by Rio Tinto and Alcoa, “which is focused on decarbonising aluminium smelting, and completely reworks the process such that instead of producing greenhouse gas emissions, the process emits only oxygen.” Elysis expects its product to reach commercialisation by 2024.

Decarbonising the supply chain for EV batteries

At the end of 2020, Engie Impact, which launched in the APAC region in June last year, announced the completion of its zero-carbon roadmap for Vale New Caledonia (VNC), which produces nickel, primarily for the battery industry, and wants to differentiate itself from competitors with a zero-carbon product.

Under APAC Managing Director of Engie Impact, Malavika Jain Bambawale, the division undertook a study to provide insights into the possible pathways for VNC to achieve zero carbon within two decades, taking into account the expected increase in energy consumption over that period.

It weighed up trade-offs between energy and carbon savings, capital and operational expenditures and return on investment, and leveraged Engie’s expertise in renewables, renewable hydrogen, energy storage and zero-carbon mobility options.

“Working with ENGIE we knew that we would be able to establish how to best innovate our plant to not only reach our intended goal but to also do so competitively,” said VNC Energy Transition Manager, Sylvain David, at the time.

The company had also identified that to ensure an end-to-end carbon free product, the whole value chain of electric vehicles to which it was contributing would also need to be decarbonised.

Accounting for emissions avoided

This raises another challenge for companies that are mature in their decarbonisation approach, which is how to account for avoided emissions, aka Scope 4 emissions.

In 2013, the GHG Protocol identified avoided emissions as emission reductions which occur outside a product’s lifecycle or value chain, but as a result of the use of the product.

Engie defines its accounting methodology as a way to measure a company’s contribution, via its products, to the decarbonisation of its customers.

There is currently no standard, or robust accounting for how organisations define the quantity of avoided emissions associated with the use of their products and services; the emergence of different frameworks in different jurisdictions creates the potential for companies to use the most favourable to their operations.

A principled approach to the numbers

Engie Impact has developed six principles that guide this accounting and how to communicate the results.

The principles in brief are: identify the scope of assessment; establish a credible baseline; ensure calculation consistency; use pragmatic accounting; manage double counting; and implement transparent, verifiable and separate communication.

“It adds a level of rigour to companies’ desire to claim avoided emissions, and also puts in place a standard to overcome any greenwashing that might occur in stating them,” says Martin.

The intention is to give companies confidence in their numbers around avoided emissions. “Standardisation of the approach is key because it puts everyone on a level playing field in how to implement this accounting,” says Martin.

Engie hopes its methodology will be quite widely adopted, so that as organisations in similar spheres put the principles in place, they can compare similar products to see which has more or less of an environmental impact, and the figures will spur an element of competition to legitimately improve decarbonisation performance.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

2 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.