Through the Australian Renewable Energy Agency (ARENA) the Federal Government has committed $1.27 million to University of Newcastle spin-off MGA Thermal to help finance the construction of a 5 MWh thermal energy storage pilot project in the Hunter region of New South Wales.

The $2.85 million project will showcase MGA Thermal’s proprietary Miscibility Gap Alloy (MGA) technology, a material which co-founder and chief executive officer Erich Kisi said will play a critical role in the nation’s energy transition, because it will make it possible to retrofit existing thermal power plants with renewable storage technology.

“If the current industry sentiment and the impacts of climate change are telling us anything, it’s that we can no longer hold off on the renewable energy transition,” he said.

“While conventional storage technologies like batteries play an important role, a complementary, grid-scale dispatchable energy solution is required to power a seamless transition to renewables nationally.”

To be located at MGA Thermal’s facility in Tomago, Kisi said the pilot plant will have charging and discharging capabilities of up to 500 kW and will help take the company’s technology from lab to market.

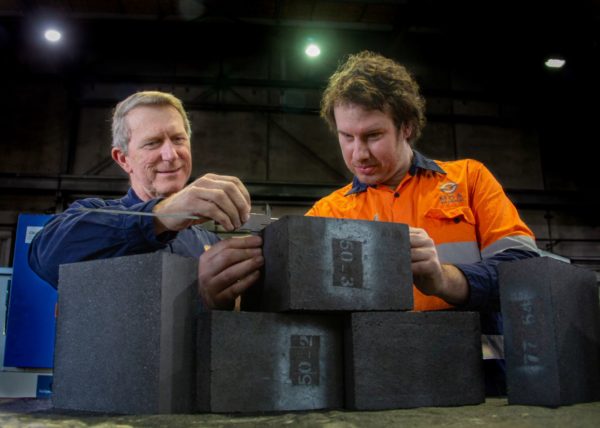

The company’s patented thermal energy storage blocks, approximately the size of a large brick, consist of small alloy particles embedded within graphite-based blocks enclosed in a fully insulated system. Once heated the alloy particles, which melt and solidify for many thousands of cycles, can store heat for days with minimal energy loss.

Image: MGA Thermal

“It accepts energy in the form of electricity renewably generated electricity, ultimately, that heats up the blocks,” Kisi said. “And they sit at around 600 degrees Celsius, storing heat almost indefinitely. It loses very little heat over time. And then the energy is dispatched by making steam, high-temperature, high-pressure steam for power generation, or we can derate it to address the harder-to-abate markets like process heat in industry.”

The pilot plant is expected to be commissioned in December of this year with Kisi saying it is the next step of commercialisation for MGA Thermal’s technology which “can be scaled up many hundreds of times bigger” than the planned 5 MWh pilot plant.

The company said the plant will provide performance data on charging and discharging behaviour, fluid dynamics and temperature distributions, and validate the efficacy of mid-to-long term thermal storage in a practical system. It will also offer a tangible demonstration of MGA technology for prospective customers.

With significant investment in flexible and dispatchable capacity required to support the uptake of variable renewable energy, particularly as thermal assets retire in the coming decades, ARENA chief executive officer Darren Miller said MGA’s technology has the potential to be a cost-effective medium-duration storage technology due to its energy density, low-energy degradation, modular design and low cost.

“The electricity transition is going to require a variety of storage technologies that are able to discharge over a range of timeframes from hours to days,” he said. “MGA Thermal’s novel approach could make a real difference in the medium and longer-term storage category, supporting hydrogen and pumped hydro.

“With potential deployments for industrial heating end uses, MGA Thermal could play a valuable role in decarbonising both the electricity grid and heavy industry, which often requires high-temperature heat and steam for their manufacturing needs.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.