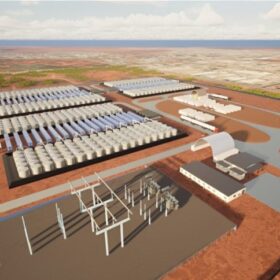

Energy Renaissance is preparing to transfer its lithium-ion battery manufacturing operations into a new $28 million purpose-built facility in the New South Wales Hunter region as it looks to ramp up production of its superStorage series of batteries to 5.3 GWh per annum to cater for domestic and international demand.

Energy Renaissance founder and development director Brian Craighead said the new 4,500-square-metre Renaissance One plant at Tomago, just north of Newcastle in the Hunter Valley, will have an initial battery production capacity of up to 300 MWh per annum, with plans to scale the operation up to 5.3 GWh.

“Just a few years ago we were told it wasn’t possible to manufacture in Australia. Today, in the shadow of our soon-to-be-completed Renaissance One facility I can tell you that it is absolutely possible to manufacture in Australia,” he said.

The shift to the new facility follows the successful completion of a pilot program backed by the federal government’s Advanced Manufacturing Growth Centre (AMGC). The pilot program, conducted at Energy Renaissance’s existing facility at Tomago, allowed the company to develop, test and document its technology, systems and processes and commence operations to supply to customers ahead of full-scale manufacture.

Image: Supplied

Energy Renaissance is currently producing up to 4 MWh of lithium-ion batteries per month for use in industrial and commercial applications but that will scale up significantly when operations are transferred.

The company said the Australian-made batteries, designed to cope with high temperature and humidity environments, will be used in stationary (grid and microgrid, renewables, community storage, mining electrification) and transport (buses, light commercial and industrial vehicles) applications. It is looking to supply both the local and export markets.

Energy Renaissance is aiming to leverage local suppliers and supply chain to make batteries that are as close to 100% Australian content as possible. The company, which continues to import battery cells, said supply partnerships mean 92%, or 32 of the 35 components that make up the company’s superStorage range of batteries are produced by or sourced from Australian companies.

Image: Supplied

“With the support of organisations such as AMGC and our partners, we have been able to develop a world-leading lithium-ion battery for domestic and export use and soon, we hope to expand the impact of this program to add value to Australia’s abundant raw materials by embarking on cell manufacture,” Craighead said.

AMGC managing director Jens Goennemann said Energy Renaissance is “proof positive” that Australia can be a world leader in the renewable energy industry.

“Energy Renaissance’s approach typifies how we should be seeking to move away from our reliance on raw commodities and tap into our abundant human, commodities and manufacturing prowess to transform it into complex goods for local and export markets,” he said.

“Energy Renaissance didn’t stop when they developed a battery for hot and humid climates, they embarked on commercialising the technology … they are a shining light for others to follow.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Nice commentary but pity u got it wrong as the factory will produce sodium ion batteries according to another news article. These were invented at Brisbane university .

Thanks for your comment Jaz, but the article is correct. The Energy Renaissance gigafactory at Tomago will produce lithium-ion batteries. See here: https://energyrenaissance.com/amgc-announces-pilot-completion/

Regards, pv magazine Australia editorial staff.