The Clean Energy Regulator is currently exploring how to define low-emissions hydrogen production through a Guarantee of Origin (GO) scheme for Australia. Such a scheme could set a threshold level for carbon emissions from the production process in order to classify it as being ‘clean’, similar to schemes in operation internationally, including in the United Kingdom and Europe.

In this Chart of the Week, we explore how ‘clean’ the hydrogen produced in Australia by a grid-connected electrolyser could be, depending on its location and change in variable renewable energy (VRE) penetration into the grid over time. Previously, we have also explored how the economics of grid-connected electrolysers can be improved through the addition of a battery or by accessing FCAS market revenues.

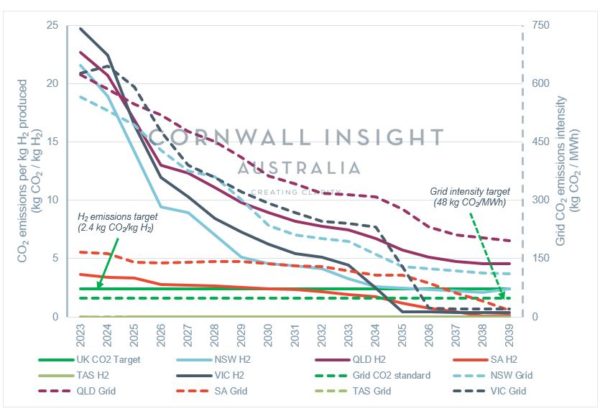

For a grid-connected hydrolyser, the emissions intensity of the hydrogen produced will be linked to the average emissions intensity of the grid’s generation sources at the time of its production. For benchmarking, we assume an electrolyser energy efficiency of 67% and use the U.K. Guarantee of Origin threshold (20 g CO2/MJ-H2, or 2.4 kg CO2/kg), which corresponds to a required grid emissions intensity of 48 kg CO2/MWh or below to produce hydrogen that meets the standard. For context, the average grid emissions intensity across New South Wales, Victoria and Queensland in 2022 is between 550-650 kg CO2/MWh.

As seen in the dashed lines in Figure 1, within the NEM, Tasmania is the only region where the average carbon intensity of the grid is already below the U.K. standard. According to our Benchmark Power Curve (BPC) forecasts, Victoria and South Australia will be the next two regions to fall below 48 kg CO2/MWh in 2035 and 2037, respectively, while NSW will follow in 2041. Queensland does not cross the threshold within the BPC forecast window to 2050. However, the recently announced Queensland Energy and Jobs Plan is expected to change this.

Image: Cornwall Insight Australia

On a time-of-day basis, there is generally a higher share of VRE during the daytime hours, such that selectively producing hydrogen during the day would result in a ‘cleaner’ product. Wholesale energy prices are also generally lower during these times, so utilising lower daytime energy costs can be expected to reduce emissions intensity.

In the solid lines in Figure 1, we have modelled the carbon emissions over time from a 500 kW grid-connected electrolyser, capable of producing hydrogen at a maximum rate of 5 kg/hr but set to run at an averaged capacity factor of 30% (close to the typical capacity factor of solar and wind generators), with the simulation solving for the lowest cost of production. This analysis has not considered standby energy consumption (for keeping the electrolyser online while not actively producing hydrogen).

By utilising grid energy at the optimum times of the day, the emissions intensity of hydrogen produced in this scenario tracks ahead of the forecast of averaged grid emissions intensity over time, with hydrogen from SA crossing below the U.K. scheme threshold in 2031, Victoria in 2035 and NSW in 2036. Tasmanian-produced hydrogen is already well below the threshold, while Queensland-produced hydrogen still does not fall below the threshold within the forecast window.

Connecting a hydrogen electrolyser to the grid can offer several other benefits, including:

- Operating with more consistent power input than relying only on variable renewable energy (VRE) generation. As the VRE generation may vary, this could result in differing hydrogen production rates throughout the year

- Achieving larger hydrogen output levels and higher capacity factors, allowing equipment capital costs to be spread over a larger output to reduce the per-kg cost

- Locating the electrolyser at a transport or export hub rather than co-located with VRE generation can significantly reduce costs associated with transporting hydrogen.

Author: Con Dimitrakakis, Energy consultant, Cornwall Insight Australia

The views and opinions expressed in this article are the author’s own, and do not necessarily reflect those held by pv magazine.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.