Researchers from the Australian Research Council (ARC) Centre of Excellence in Exciton Science, based at Melbourne’s Monash University, say they have demonstrated a new way to create stable perovskite solar cells that last much longer than their predecessors, helping make the technology commercially relevant.

The making of perovskite cells generally relies on the use of lead halides and requires the inclusion of strong solvents to control the crystallisation process, a process that can lead to defects in the thin films, which causes the resulting device to rapidly lose efficiency. It’s also hard to control.

The researchers, together with colleagues from Wuhan University of Technology in China, said the chemical compound lead acetate has emerged as a promising alternative precursor, because it can create ultrasmooth thin films with fewer defects.

Until now, lead acetate had only been used to make methylammonium or cesium-based perovskites, which are relatively unstable and not suitable for real-world applications. The research team said a better candidate for commercial use can be found in perovskites made using formamidinium and caesium, thanks to their superior stability.

Previous attempts to synthesise them using lead acetate as the precursor failed but Dr Sebastian Fürer from Monash University said to solve this issue, the researchers had used ammonium as a volatile cation (positively charged ion) at a critical stage.

“The presence of ammonium served to drive away the residual acetate during annealing, without forming unwanted side products,” he said.

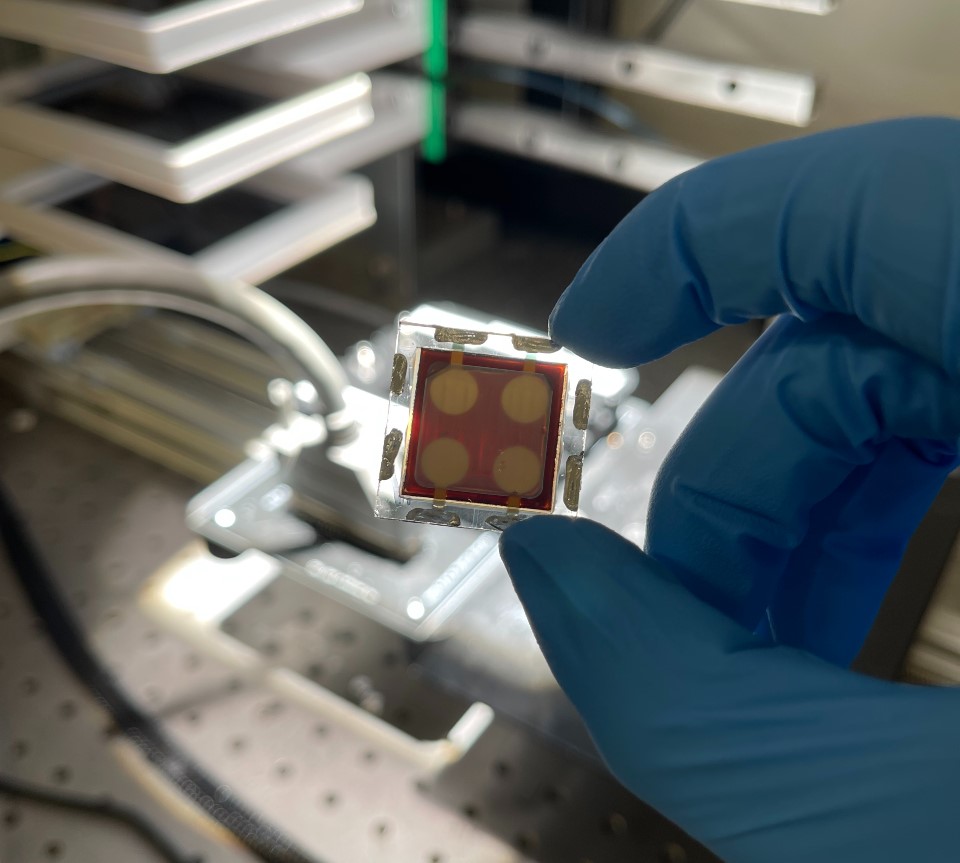

Image: Monash University

The researchers said the cells recorded a conversion efficiency of 21%, the best results yet recorded for a device made from a non-halide lead source. A mini prototype solar panel featuring the cells achieved 18.8% efficiency.

Monash University PhD student Jie Zhao said the test devices also showed strong thermal stability, continuing to function with no efficiency loss after 3,300 hours running at 65°C.

“We’ve been able to use lead acetate in a one-step, spin-coating process to get the perfect, high-quality formamidinium-caesium perovskite thin film,” he said. “And because we don’t need an anti-solvent agent, we can do this via large-scale techniques, such as blade coating, which means it’s viable at industrial scale.”

The results have been published in the journal Energy and Environmental Science.

In a corresponding work, another team of researchers from the ARC Centre of Excellence in Exciton Science have demonstrated a new way to improve the stability of perovskite cells, leading to thin films which they said are of greater quality, with reduced defects and enhanced stability.

The researchers said by removing the solvent dimethyl-sulfoxide and introducing dimethylammonium chloride as a crystallisation agent, they were able to better control the intermediate phases of the perovskite crystallisation process.

Image: Monash University

The researchers, working with scientists from Oxford University in the UK, said groups of up to 138 sample devices were subjected to an accelerated ageing and testing process at high temperatures and in real-world conditions. The formamidinium-caesium perovskite cells created using the new synthesis process significantly outperformed the control group and demonstrated resistance to thermal, humidity and light degradation.

During testing, the best device operated above the T80 threshold for more than 1,400 hours under simulated sunlight at 65°C. (T80 is the time it takes for a solar cell to reduce to 80% of its initial efficiency).

Beyond 1,600 hours, the control device fabricated using the conventional dimethyl-sulfoxide approach stopped functioning, while devices fabricated with the new, improved design retained 70% of their original efficiency.

The same degradation study was performed on a group of devices at 85°C, with the new cells again outperforming the control group.

The researchers calculated that the new cells age by a factor of 1.7 for each 10°C increase in the temperature they are exposed to, which is close to the two-fold increase expected of commercial silicon devices.

Oxford University PhD student Philippe Holzhey said the work, published in the journal Nature Materials, is a strong step forward to matching commercial silicon’s stability and makes perovskite-silicon tandem devices a much more realistic candidate for becoming the dominant next-generation solar cell.

“It’s really important that people start shifting to realise there is no value in performance if it’s not a stable performance,” he said. “If the device lasts for a day or a week or something, there’s not so much value in it. It has to last for years.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.