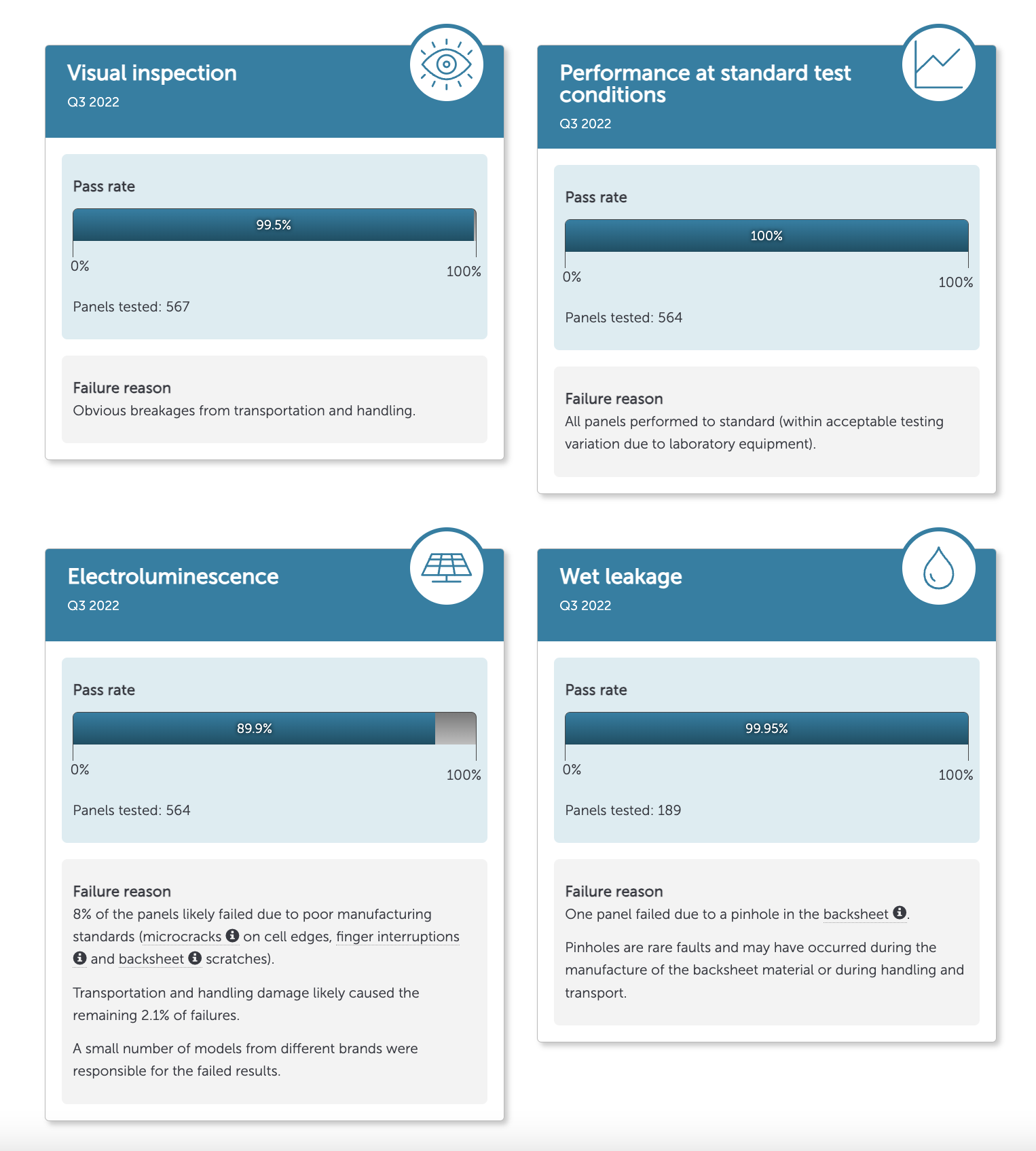

The Clean Energy Regulator (CER) has found very few modules supplied to the Australian marketplace do not meet required standards for safety and performance. The testing program, developed and rolled out in 2022, found that Australian standards are being met by an overwhelming majority of modules, with approximately 10% failing under EL examination.

The CER is conducting the testing program as a part of its oversight of the Small-Scale Renewable Energy Scheme (SRES). The positive results can give confidence to Australian home and small business owners. The small number of failures provide important quality lessons for the Australian solar industry.

The testing program is being rolled out by the CER in partnership with an independent testing laboratory. The unnamed lab specified testing sample sizes, acceptance levels, sampling methods, and nominated the manufacturers and models to be testing.

The CER reports that the modules tested in the first round of its program are representative of 71% of modules in the Australian rooftop marketplace in 2022.

In its first round, 567 modules were tested between January and March 2022. 18 module series were tested, from 14 manufacturers.

The testing program included visual inspection, EL testing, power output under standard test conditions (STC), and a wet leakage test. Aggregated test results are made available on the CER website. Testing was carried out in accordance with International Electrical Commission (IEC) standards.

Inside failures

Damage during transportation and handling was responsible for some of the module failures. Of the 0.5% of modules that failed visual inspection, the CER observes there were “obvious breakages.” Under EL testing, the 2.1% of failures were thought to be after manufacture.

The EL test results showed microcracks on cell edges, finger interruptions, and backsheet scratches. Cell edge cracking can be more prevalent than in the past due the widespread adoption of half-cut cells in production and the larger, thinner wafers being used. Finger interruptions can be caused by soldering defects – commonly described as “cold soldering.” 8% of the EL test failures were attributed to manufacturing defects.

In the 0.5% of modules that failed the wet leakage test, pinholes were observed on the backsheet. This can allow for water ingress or, in the worst cases, current leakage.

Despite the defects either in production or production, the CER found that “no significant safety risks [were] identified.”

The CER did not test for potential induced degradation (PID), or other degradation effects, but says that PID testing will be added to future rounds of the program.

Modules that fail under the testing program and investigated and further testing may be carried out. The CER says that panels can be declared ineligible under the SRES is they do not meet Australian standards, pose a risk to the integrity of Small-scale Technology Certificates, or were approved “based on false or misleading information.” If a module is found to ineligible under the SRES, STCs cannot be claimed.

The Quarter 3, 2022 testing round results were published on Jan. 31.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.