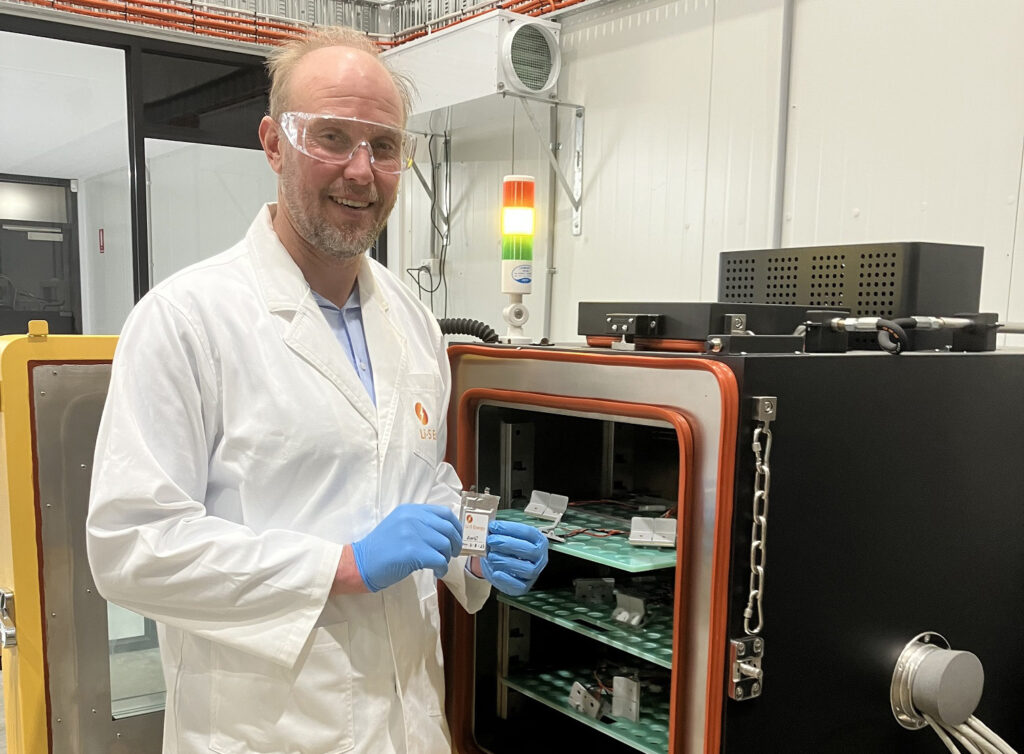

The commission of new equipment at the Li-S Energy facility in Geelong, Victoria will enable advanced cell performance testing and the delivery of test and trial cells.

The production line has 19 manufacturing stages from cathode power preparation and ball milling through to cell fabrication and formation cycling, with the engineering team receiving and installing a bespoke lithium foil anode cutting line and primary cell fabrication equipment.

Lee Finniear, the of CEO Li-S Energy, said as the largest advanced pouch cell production line and largest battery dry room in Australia, the facility will scale their ability to produce high quality, commercial sized pouch cells by orders of magnitude.

“We can advance our cell performance testing and be capable of providing thousands of test and trial cells to our current and future partners. Eighteen months ago, we made a commitment to scale up our production capability and as we advance the Phase 3 production line commissioning, I am delighted that we have met this substantial milestone on time and within budget,” he said.

Li-S Energy has sought to create a lightweight lithium sulfur battery with a cycle of life approaching lithium ion with over a decade of research into the use of Boron Nitride Nanotubes (BNNTs) and advanced battery technologies. The company has secured a patent patent for “flexible lithium sulfur batteries”.

In April 2023, Li-S partnered with drone developer and operator V-TOL Aerospace and Wagga-based advanced solar panel maker, Halocell Energy, which is focused on commercialising Perovskite Solar Cells (PSC), to test and develop Australian-made Low and High-Altitude Long Endurance (HALE) drones using Li-S Energy’s lithium sulfur batteries.

Halocell’s solar cells are custom designed to maximise energy harvesting efficiency and the integration of these cells into the drone’s structure will allow it to harness solar energy during day flight, supplementing the battery and significantly extending the aircraft’s range.

Halocell’s CEO, Paul Moonie said the company’s cells will add an entirely new dimension to flight time and efficiency.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

2 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.