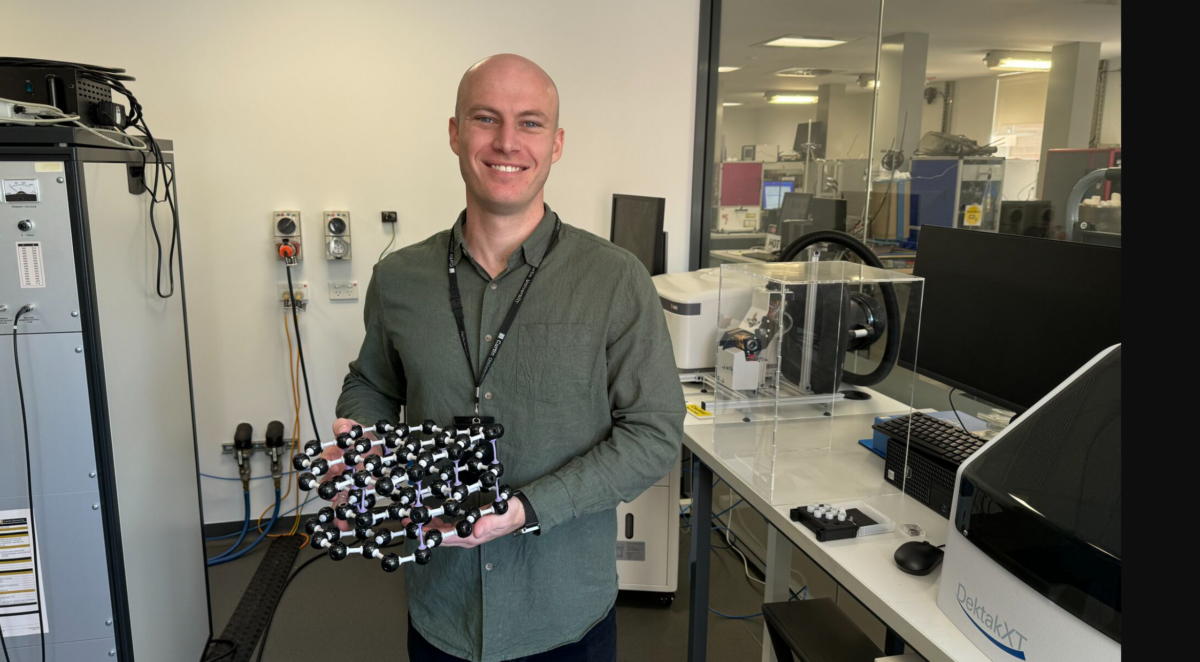

Perth-headquartered startup RapidGraphite, co-developed by Curtin University research academic and material scientist Dr Jason Fogg, has developed the technology that transforms waste carbon into high-purity graphite, a key ingredient in lithium-ion batteries.

The technology, called Rapid Pulse, utilises repeated high-temperature pulsing of carbonaceous materials to produce highly ordered graphite with very few defects in less than 10 seconds.

Fogg said the technology has the potential to meet demand for the critical mineral needed for lithium-ion batteries and other decarbonisation technologies, noting that he has experimented with materials generally considered incapable of producing highly crystalline graphite, including polyvinylidene chloride commonly found in food wrap and medical packaging, and cellulose.

“With RapidGraphite’s proprietary technology, we can bring a world-first solution to graphite manufacturers to help them turn their waste carbon into battery-grade graphite, overcoming technical bottlenecks that exist today,” Fogg said.

RapidGraphite is one of four ventures that have won a spot in Curtin University’s $18.6 million Venture Studio with the projects to receive a combined $3 million in capital investment and support to develop sustainable business models.

The capital investment platform aims to fast-track innovation and develop new technologies to support Australia’s transition to net zero.

Fogg said the support will help the RapidGraphite team bring its technology into the world commercially.

“Our team is excited,” he said. “We see it as an opportunity to bring RapidGraphite out of the university and into the world.”

Curtin University Program Director Rohan McDougall said the Venture Studio will help attract private-sector investment into fledgling companies that can enhance Australia’s critical minerals downstream capabilities, specifically in the development of clean technology products.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

2 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.