Independent think tank Climate Energy Finance (CEF) has called for a national green iron and steel strategy, a $20 billion (USD 12.9 billion) Future Fund mandate to enable renewables-powered processing of green metals and for measures to accelerate investment in firmed renewable energy at scale.

A key recommendation from a new CEF report, Green Metal Statecraft: Forging Australia’s Green Iron Industry, is that firmed renewables infrastructure deployment rates are accelerated and approvals for net zero projects prioritised, fast-tracking development of renewably-powered industrial hubs.

A Renewable Energy Approvals Initiative created for distributed behind-the-meter generation and storage projects that will power green hydrogen production and electricity demand for value-added projects critical to underpinning the federal government’s Future Made in Australia initiatives is recommended, the report says.

Establishing capabilities in production of green iron and value-adding iron ore onshore pre-export using firmed renewables would minimise a risk of halving Australia’s $138 billion iron ore export revenues, as global importers, including China, decarbonise and restructure their steel supply chains and reorient to regions.

CEF Net Zero Transformation Analyst and lead author on the report Matt Pollard said Australia’s world leading iron ore producers have extracted huge returns on investment as China prioritised expansion of its steel mills.

“However, China likely has peaked in steel output, and we are now at the precipice of a rapid shift towards decarbonisation in our largest and most profitable export market, with major implications for Australian iron ore exports,” Pollard said.

“This pivot will require a massive re-orientation of steel supply chains to regions with advantages such as exceptional renewable energy resources – like Australia, potentially. But this is a global race.”

“As we showcase through the report, other jurisdictions are rapidly emerging to become global hubs for lower-emission iron and steel production. Australia’s advantage, producing low-cost, high-margin, mid-grade unprocessed iron ore, is under threat,” he said.

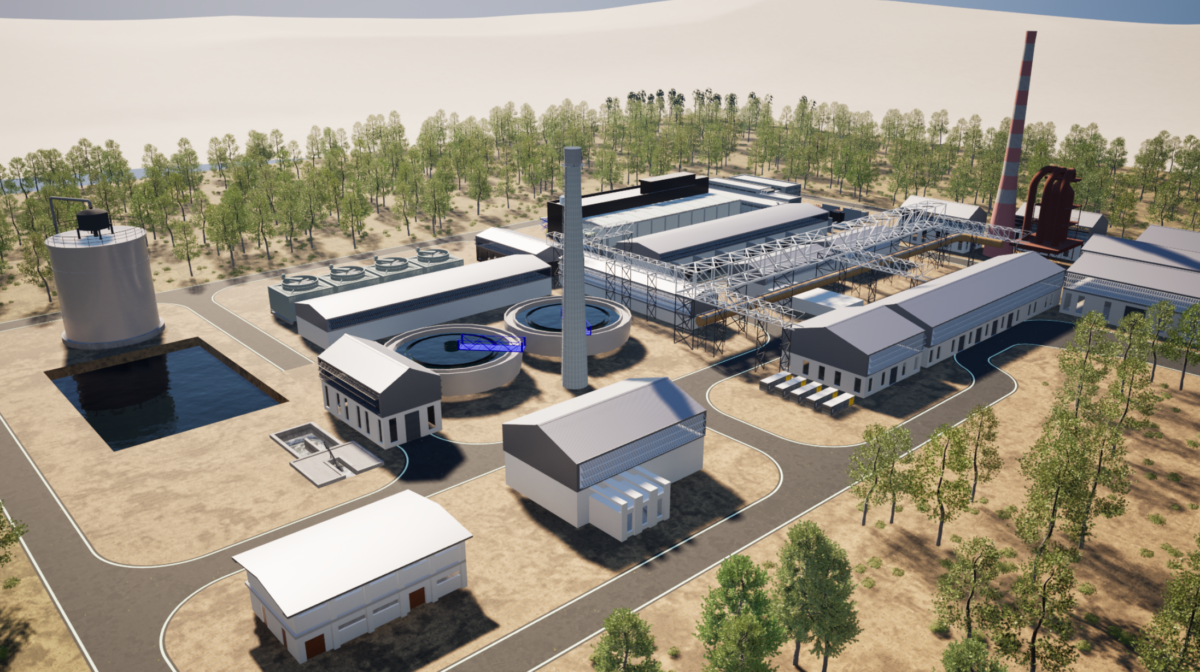

Industry is already exploring green iron production processes, including Fortescue Metals Group (FMG), which is developing a pilot plant at its Christmas Creek iron ore mine near Port Hedland in the Pilbara region of Western Australia, using solar farms to produce from 2025 up to 1,500 tonnes per year of high purity green iron.

The Christmas Creek Green Metal Project will also use green hydrogen produced at an existing Christmas Creek facility and demonstrate a ‘green pit to product’ supply chain, while the company’s Perth research centre is developing a low-energy direct electrochemical reduction process (LEDER) to convert Pilbara iron ores into green iron metal.

The LEDER technology is an iron ore electrolyser designed to use intermittent renewable energy to produce green iron feed for steelmaking at low temperatures and is an alternative electrochemical pathway for iron ore reduction that avoids use of hydrogen gas.

United Kingdom headquartered renewable infrastructure investor Quinbrook Infrastructure Partners is developing a green iron project drawing on renewable hydrogen produced by the Central Queensland Hydrogen Project (CQ-H2) near Gladstone on the central Queensland coast.

Australia is the world’s biggest iron ore exporter, with a 56% export market share and iron ore accounts for a third of Australia’s total resource and energy export revenues.

CEF Director and report author Tim Buckley said green iron is the single largest investment opportunity for Australia, but the downside risks of failure to act are profound.

“We need government financial support for the first-of-a-kind deployments of green iron at commercial scale here, to develop the “learning by doing” and supply chain capacities needed, even as we work with our key Asian trade partners to build momentum towards an explicit price on carbon emissions in regional trade to drive private investment in steel supply chain decarbonisation,” Buckley said.

“This is key to limiting the use of government subsidies, and to creating the market signal for the accelerated investment in green iron needed to help our key trade partners decarbonise their economies at the speed and scale the climate science dictates.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.