A research team from the University of New South Wales (UNSW) has investigated the degradation mechanisms of industrial TOPCon solar modules encapsulated with ethylene vinyl acetate (EVA) under accelerated damp-heat conditions and has found that degradation is primarily driven by acetic acid generation from EVA encapsulant, causing chemical corrosion.

“Our work highlights critical risks in adopting EVA encapsulation for cost-effective TOPCon module production and provides clear, actionable insights into improving TOPCon reliability for deployment in humid and hot environments,” the research’s lead author, Bram Hoex, told pv magazine. “It also offers new understanding of metallisation degradation mechanisms driven by EVA-generated contaminants and demonstrates the effectiveness of metallisation adjustments in reducing EVA-induced degradation rates.”

In the study “Is TOPCon ready for EVA? Insights from damp heat testing of glass-backsheet modules,” published in Solar Energy Materials and Solar Cells, Hoex and his colleagues explained that EVA tends to generate acetic acid (CH3COOH) over time, which can be detrimental to an EVA-encapsulated module’s power output and fill factor (FF).

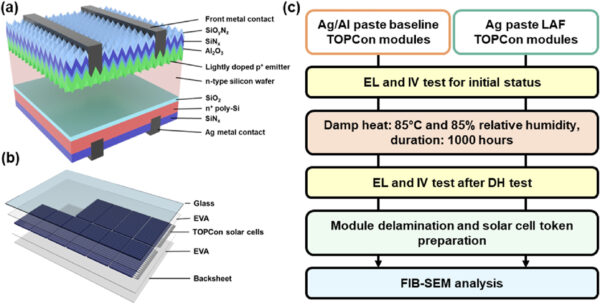

They analysed, in particular, two types of industrial EVA-encapsulated glass-backsheet TOPCon modules with different front-side metallization compounds under damp-heat conditions and two metallisation approaches: conventional silver-aluminum (Ag/Al) paste and low-Al-content Ag paste combined with laser-assisted firing (LAF).

The modules were based on 182 mm × 183.75 mm TOPCon cells based on G10 n-type Czochralski (Cz) wafers. Furthermore, UV-blocking EVA was applied to the front side and UV-transparent EVA was used on the rear side, with the backsheet being transparent with a white grid design.

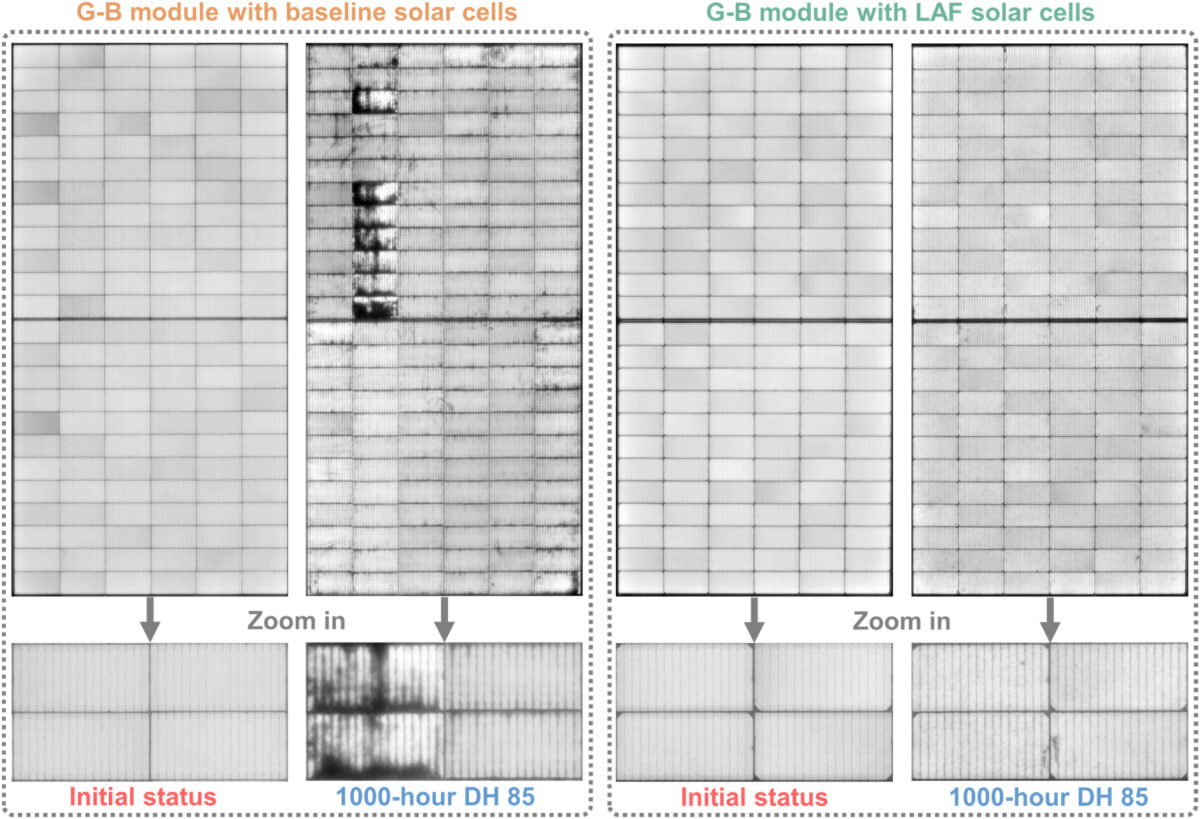

Analysed under damp-heat (DH) testing conditions, conventional Ag/Al paste modules were found to exhibit severe performance degradation after 1,000 h, with a 37.0 % relative power output loss, which was attributable to a 34.9 % reduction in FF.

Moreover, the analysis showed that the low-Al-content Ag paste with LAF substantially improved stability, with power loss and FF drop being significantly lower. Front-side contacts showed corrosion and glass-frit decomposition, which is particularly severe with Ag/Al paste, while rear-side contacts, containing tellurium (Te)-rich alloys, exhibited significant corrosion and delamination.

“These findings underscore the severe instability of Ag/Al paste, while also revealing that the EVA encapsulant contributes to degradation in low Al-Ag paste TOPCon modules, albeit to a lesser extent,” the researchers emphasised.

They also recommended reducing Al content in metallisation paste combined with LAF processing as partial mitigation and suggested that alternative encapsulants such as polyolefin elastomer (POE)] or improved metallisation strategies are adopted to achieve long-term module stability under damp-heat conditions.

Previous research by UNSW showed the vulnerability of TOPCon solar cells to contact corrosion and three types of TOPCon solar module failures that were never detected in PERC panels. Furthermore, UNSW scientists investigated sodium-induced degradation of TOPCon solar cells under damp-heat exposure.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.