Researchers from the University of New South Wales (UNSW) and China’s metallisation paste specialist Changzhou Fusion New Materials claim to have developed a silver-lean screen-printing metallisation technology that can significantly reduce silver (Ag) consumption in TOPCon solar cells without impacting device efficiency and performance.

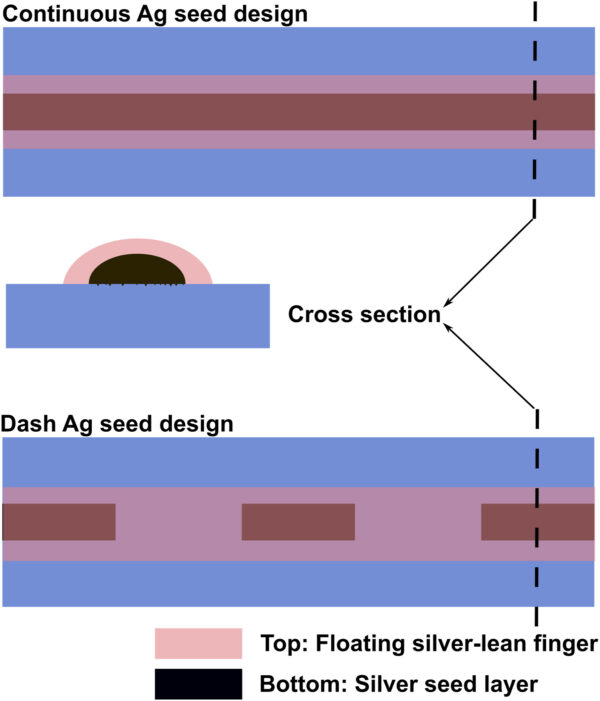

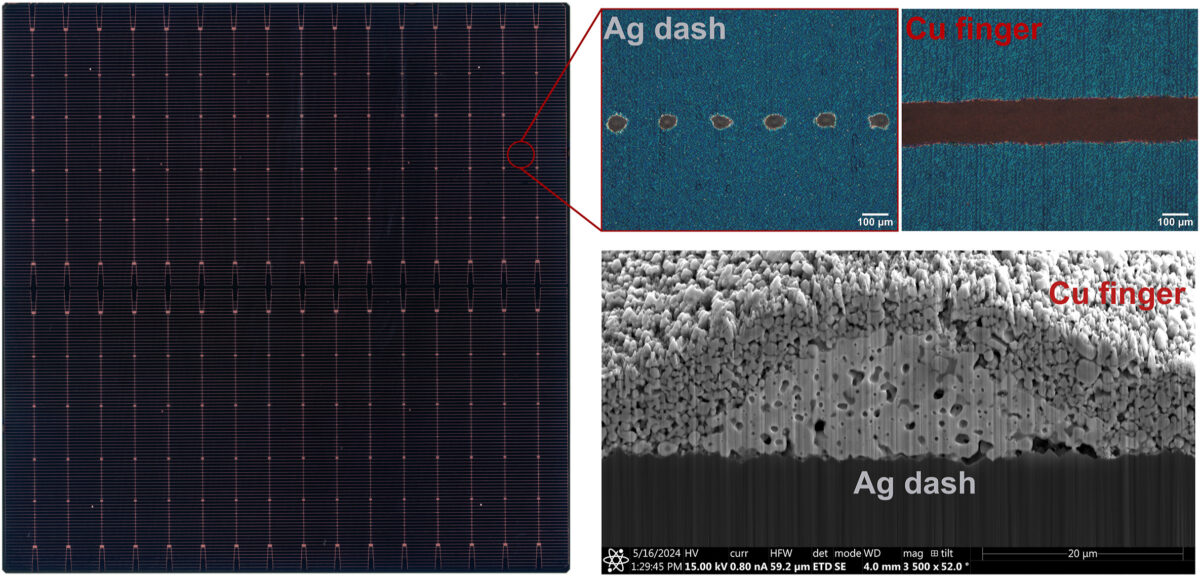

With the proposed technique, the scientists replaced the commonly used Ag fingers with intermittent Ag dashes for contact formation and Ag-free fingers and busbars for electrical conduction.

“This dual-layer configuration addresses the main challenges associated with using silver-lean paste materials in silicon solar cells by avoiding the formation of direct metal/Si interfaces with those alternative pastes,” the group said.

The novel two-step printing process is implemented first by printing conventional silver pastes as seed layers and then by printing the silver-lean fingers on top. With this configuration, the silver-lean fingers are intended for electrical conduction only, with the metal/Si interfaces being no longer essential for this purpose.

“This approach not only broadens the choices of silver-lean pastes that can be potentially used in TOPCon solar cells but also significantly eases the requirements on future paste developments,” the academics stressed.

The new metallisation technique was tested in a 25%-efficient TOPCon solar cell and was found to result in an 85 % reduction in rear-side silver usage, with total silver consumption reaching just 7 mg/W, and a 40% reduction compared to industrial TOPCon cells with standard Ag metallization.

The cell also showed a “marginal” efficiency difference of 0.1–0.2 % compared to reference cells based on standard Ag metallisation.

The scientists believe that through the optimisation of the so-called laser-enhanced contact optimization (LECO) and the commercially available pastes for the dash design, the efficiency gap can be reduced or even eliminated.

“As another appealing option, the use of Ag dashes in conjunction with aluminum (Ac) fingers was found to be challenging due to the undesirable interaction between Ag and Al pastes during the co-firing process,” they also explained. “Further developments and optimisations in existing industrial standard Ag and Al pastes will be critically needed to overcome such a challenge.”

Their findings are available in the paper “Silver-lean screen-printing metallisation for industrial TOPCon solar cells: Enabling an 80% reduction in silver consumption,” which was recently published in Solar Energy Materials and Solar Cells.

Previous research on TOPCon by UNSW showed the vulnerability of TOPCon solar cells to contact corrosion and three types of TOPCon solar module failures that were never detected in PERC panels. Furthermore, UNSW scientists investigated sodium-induced degradation of TOPCon solar cells under damp-heat exposure and degradation mechanisms of industrial TOPCon solar modules encapsulated with ethylene vinyl acetate (EVA) under accelerated damp-heat conditions.

More recently, another UNSW team has found that the Special Injected Metallisation (JSIM) technique developed by Chinese manufacturer Jolywood can considerably increase TOPCon solar cell efficiency. The scientists described precisely how laser-assisted firing enhances cell performance, reportedly filling critical gaps in industrial TOPCon cell optimisation.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.