Researchers at the University of New South Wales (UNSW) have identified five different “hidden contaminants” that could potentially exacerbate damp heat (DP)-induced degradation in solar cells and modules based on tunnel oxide passivated contact (TOPCon) or heterojunction (HJT) design.

“HJT and TOPCon are much more sensitive to contaminants, even minute handling lapses can negate efficiency gains and inflate warranty risk,” the research’s corresponding author, Bram Hoex, told pv magazine. “Solar cell handling can result in damp heat failures along the line.”

The scientists identified, in particular, five contaminants – sodium (Na), calcium (Ca), magnesium (Mg), chlorine (Cl), and sulphur (S) – and said their presence could originate from improper handling during cell or module processing, such as contact with contaminated gloves, cassettes, packaging, or vacuum grippers.

They stressed that these contaminants may be deposited on cell surfaces or staging areas before the module encapsulation step and have an impact on passivation layers and cell metallisation or in the case of HJT products on transparent conductive oxides (TCOs) and amorphous silicon (a-Si) layers.

The research team conducted a series of damp heat (DH) tests with glass-backsheet TOPCon, HJT and PERC solar modules encapsulated with ethylene vinyl acetate (EVA). The panels were produced between 2019 and 2024 and supplied by undisclosed manufacturers.

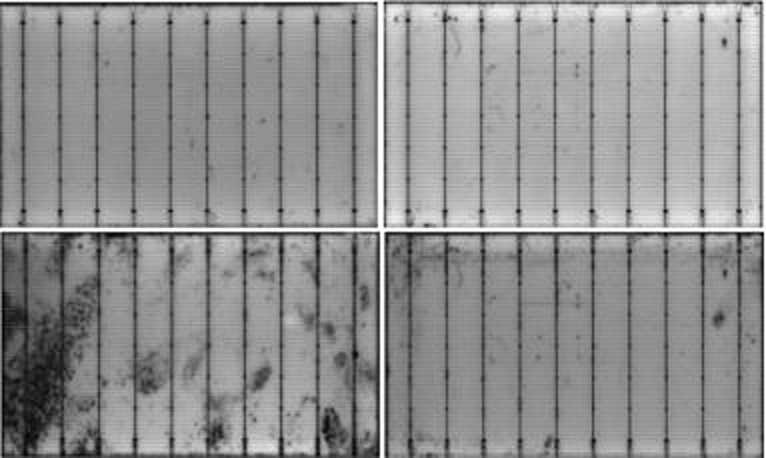

The analysis showed that the PERC modules remained “largely” unaffected, while both the TOPCon and HJT panels suffered significant power losses.

“We found that invisible contaminants matter,” Hoex said. “Traces of Na, Ca, Mg, Cl and S introduced during routine handling triggered 10–16 % power loss in HJT and TOPCon glass-backsheet mini-modules after 1,000 h at 85 C/85% relative humidity.”

He also stressed, however, that “failure signatures differ,” with HJT cells showing open-circuit voltage and short-circuit losses due higher recombination, and TOPCon counterparts suffering a 41% rise in series resistance.

“Under damp heat test conditions, these contaminats likely chemically react with moisture,” Hoex said. “This reaction may have promoted charge-carrier recombination in HJT cells and metal contact corrosion in TOPCon cells, thus exacerbating performance degradation.”

In order to avoid these degradation risks, the academics recommend adopting clean-as-you-go protocols such as fresh nitrile gloves, cleaned cassettes and vacuum grippers, as well as a quick DI-water rinse and N₂ dry before encapsulation if needed.

“When these steps were implemented, both HJT and TOPCon cells remained stable under the same damp-heat stress, and subsequent manufacturing batches showed no localised failures,” Hoex said. “The mitigation protocol is low-cost and immediately actionable, allowing manufacturers to keep lighter glass-backsheet designs without resorting to expensive glass-glass or exotic encapsulants.”

The research findings are available in the study “Hidden traces: Insights into how solar cell handling drives damp-heat failures in HJT and TOPCon modules,” published in Solar Energy Materials and Solar Cells.

Previous research by UNSW showed degradation mechanisms of industrial TOPCon solar modules encapsulated with ethylene vinyl acetate (EVA) under accelerated damp-heat conditions, as well as the vulnerability of TOPCon solar cells to contact corrosion and three types of TOPCon solar module failures that were never detected in PERC panels. Furthermore, UNSW scientists investigated sodium-induced degradation of TOPCon solar cells under damp-heat exposure.

Moreover, another UNSW study recently assessed the impact of soldering flux on heterojunction solar cells and found that the composition of this component is key to preventing major cracks and significant peeling.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.