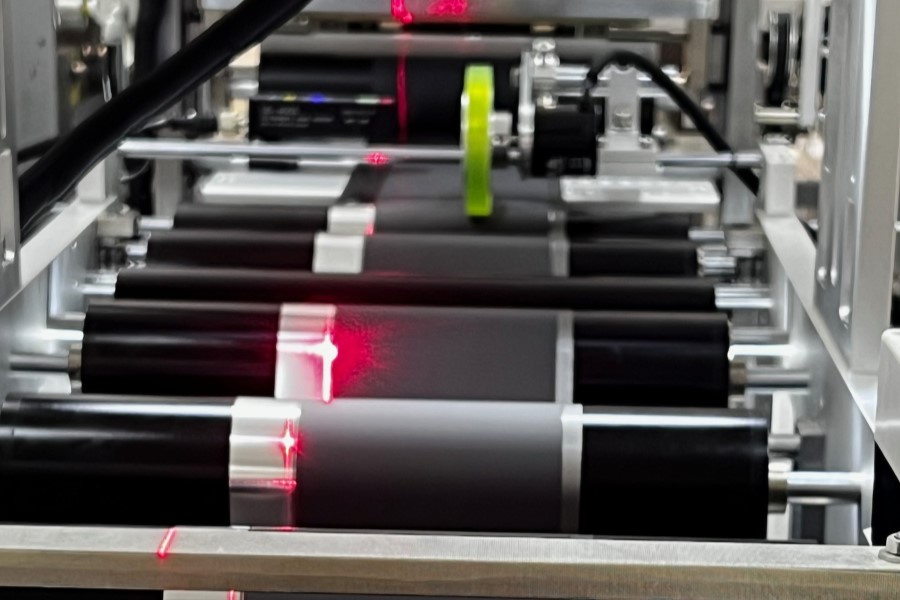

Australian battery technology developer Li-S Energy says it has established a new sovereign manufacturing capability with the successful production of 100-micron thick pure lithium metal foils at its 2 MWh cell production line in Geelong.

The company said the domestic production of high-quality lithium foils enables it to eliminate reliance on imported lithium foils used in manufacturing the anode for its lithium-sulfur and lithium metal batteries.

Li-S Energy Chief Technology Officer Steve Rowlands said the new manufacturing capability will reduce material lead times and costs, and enhance the quality and consistency of its battery cells.

“By producing foils in-house, we have tighter control over thickness, purity and handling conditions, all of which are critical for performance and safety,” he said.

“This milestone accelerates our ability to develop custom anode architectures, supports higher throughput in our pouch cell line, and enables more rapid technology iterations.”

Li-S Chief Executive Officer Dr Lee Finniear said the domestic foil production supports Australian battery supply chain resilience and marks a significant step forward for the country’s value-added lithium processing industry.

“This is a transformative moment for Australia’s battery industry,” he said. “By reducing dependence on overseas supply chains, we substantially improve our cost base, enhance cell quality, and support the resilience of Australian manufacturing.”

“It also opens the door to export opportunities as international demand for high-purity lithium foil continues to grow.”

Finniear said the manufacturing milestone, supported by a $1.76 million (USD 1.16 million) Industry Growth Program (IGP) grant from the Australian government, sets the stage for Li-S’ next manufacturing expansion.

“Under the IGP, the company will also be installing equipment to roll, laminate and coat the lithium foils, allowing it to offer a broader suite of foil products for international markets and to scale up its proprietary nano-material coating technologies,” he said.

In addition to using the lithium metal foils to further develop its own lithium-sulfur and lithium metal batteries, Li-S is offering the foils to universities, institutions and private companies conducting research and development in the battery space.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.