Engineers from Monash University in Victoria have extracted critical minerals from coal fly ash, mine tailings and old electronics, using a cleaner, more efficient way they call ‘urban mining’, which has the potential to recover 45,000 tonnes of rare earth metal annually.

Monash University Department of Chemical and Biological Engineering (DCBE) Head Professor Sankar Bhattacharya said the research shows the ash holds valuable rare earth metals essential for powering future technologies.

“Our urban mining method can recover all 17 rare earth elements with over 90% efficiency, providing a safer and more sustainable alternative to conventional mining,” Bhattacharya said.

The method allows for the recovery of magne rare earth minerals like neodymium and dysprosium, which are critical to making the powerful magnets found in electric vehicles (EVs) and wind turbines.

It could potentially recover twice Australia’s rare earth mining output produced in 2021, and nearly 30% of current global production, the researchers say, or enough to make magnets needed for about 15 million EVs.

The process has been scaled up from a small lab setup to a 30-litre system, and the researchers are now designing a 100-litre semi-continuous unit, with a demonstration plant planned at Monash University, and the technology already winning awards.

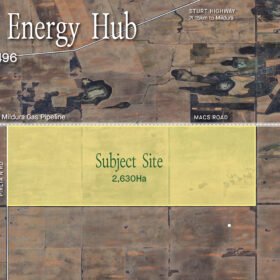

Image: Monash University

Monash University DCBE and Victorian Royal Society Young Scientist prize winner Dr Bennet Thomas said recovering rare earth elements from coal ash not only addresses a significant waste problem but also strengthens Australia’s supply chain resilience for critical materials.

“With the right support, we can scale up this technology to create new regional jobs and help Australia lead the global transition to clean energy and advanced manufacturing,” Thomas said.

Victoria’s annual output of fly ash waste is a million tonnes, while according to the Ash Development Association of Australia (ADAA) , there are 760 million tonnes of bulk volumes of coal ash materials stored across Australia, with approximately 40 million tonnes located at Portland and Wallerawang in New South Wales (NSW).

The researchers say one of the major advantages of the approach is that coal fly ash, especially the kind produced from brown coal in Victoria, typically does not contain radioactive elements such as thorium or uranium, making extraction safer.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.