Monash University researchers have developed a cobalt-iron catalyst that significantly improves the performance and enhances the lifespan of zinc-air batteries, achieving remarkable stability over “thousands of cycles.”

Zinc-air batteries have long been heralded as a potential solution for large-scale energy storage and transport applications. They have high theoretical energy density, are made from abundant and inexpensive materials, and are considered safer than many conventional alternatives.

The path to commercialisation for the technology has however been challenging with key obstacles including the slow kinetics of oxygen reduction and oxygen evolution reactions at the air cathode that leads to high charge/discharge overpotential, low efficiency, reduced energy capacity, and shorter cycle life.

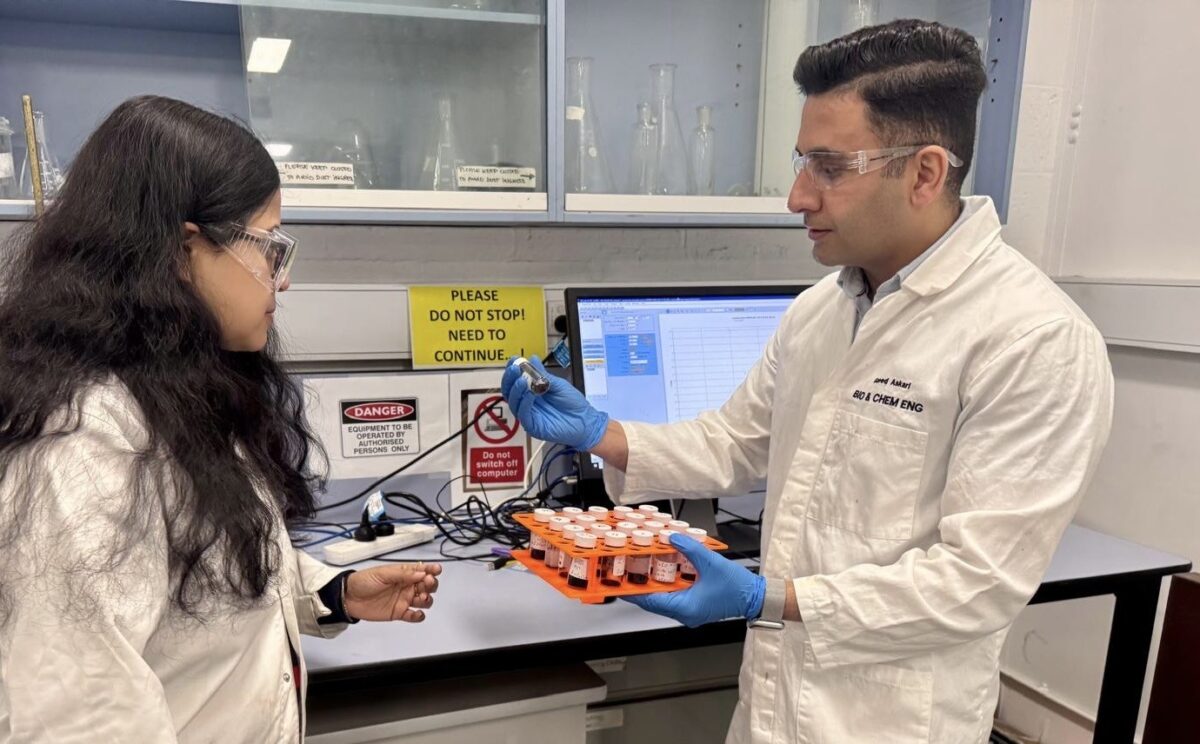

Researchers from Monash University’s Department of Chemical and Biological Engineering have now engineered a cobalt-iron catalyst, dubbed CoFe-2DSA, that makes the battery’s oxygen reactions much faster and more efficient.

Using a heat treatment, they turned a 3D material into ultra-thin carbon sheets and added individual cobalt and iron atoms to create a catalyst that co-lead author Saeed Askari said outperformed standard commercial catalysts made from expensive metals like platinum and ruthenium.

“By engineering cobalt and iron as individual atoms on a carbon framework, we achieved record-breaking performance in zinc-air batteries, showing what is possible when catalysts are designed with atomic precision,” he said.

“Our advanced simulations revealed that the cobalt-iron atom pairs, combined with nitrogen dopants, enhance charge transfer and optimise reaction kinetics, solving one of the biggest bottlenecks for rechargeable zinc-air batteries.”

The researchers reported the CoFe-2DSA battery had “outperformed commercial and reported catalysts,” achieving a power density of 229.6 milliwatts per square centimetre and an energy density of 997 Wh per kilogram.

Additionally, the electrocatalyst exhibited exceptional cycling stability, maintaining consistent performance over 74 days and 3,552 cycles.

The researchers said the results pave the way for scalable innovations, including for grid-scale energy storage applications and as an alternative to current lithium-ion batteries in electric vehicles.

“Running a rechargeable zinc-air battery continuously for more than two months is a milestone for the field,” co-lead author Dr Parama Banerjee said.

“It demonstrates that this technology is ready to move beyond the laboratory and into practical applications.”

The results appear in the research paper Synergistic electronic interplay between Co-Fe single atom and nitrogen on 2D carbon boosts bifunctional oxygen redox in metal-air batteries, published in the Nature Communications.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.