Silver traded about $74 (USD 48) per ounce on Monday, up from about USD 44 in the last week of September. The price increase and the possible crossing of the USD 50 threshold in the coming weeks or months are prompting the PV industry to intensify efforts to implement “thrifting,” or reducing silver content in cells and modules.

But how much can this process be pushed forward without affecting the quality of the PV products?

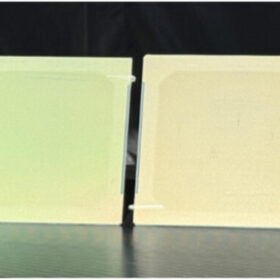

“This is not necessarily happening,” Ning Song, a researcher at UNSW, told pv magazine. “If silver reduction is well engineered with proper design and process control, it does not have to compromise the quality of solar cells and modules. The key is to adopt suitable approaches rather than simply cutting silver content.”

Andreas Lorenz, a researcher at Germany’s Fraunhofer ISE, also said the quality of solar products will not be impacted by silver reduction.

“A quality reduction of solar cells and modules would not be acceptable. I do not see any indication of a quality reduction, despite substantial silver reduction per cell,” Lorenz said.

Song noted that if silver reduction is not implemented properly, potential issues may include higher series resistance, reduced soldering quality, and long-term reliability concerns.

“These are engineering challenges that can be effectively managed through proper metallisation design and process optimisation,” she said.

Lorenz said cell interconnection using busbarless cells with multi-wire interconnection could become challenging if finger height becomes too low, potentially causing local connection problems between wires and printed or fired contacts.

“However, I am very confident that these challenges will be solved in mass production,” he added.

Song said researchers are focusing on replacing silver with cheaper metals like copper, aluminum, or nickel and on optimising interconnection designs.

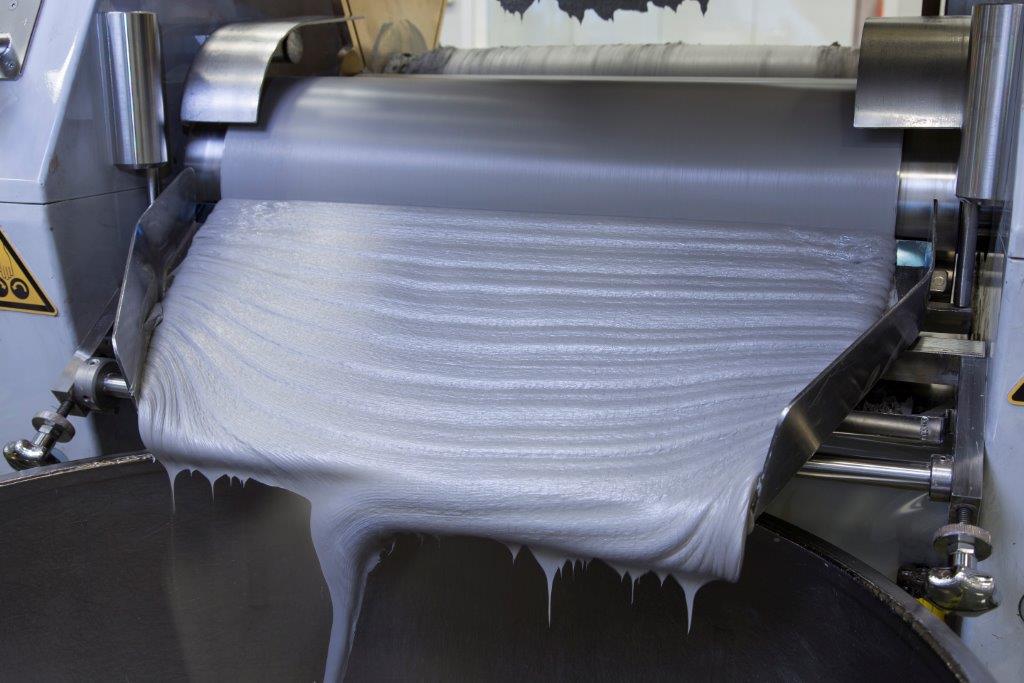

“For example, multi-busbar (MBB) and busbar-less layouts at the module level can help reduce silver consumption while maintaining performance,” she said. “In addition, fine-line full-open stencil screen printing and copper electroplating are being actively explored as potential silver-reduction technologies.”

The scientists told pv magazine that they are convinced the industry will intensify efforts to reduce or even replace silver with copper in the coming years.

“We believe rising silver prices are driving strong interest in alternative metallization approaches, including copper, nickel, aluminum, and various hybrid solutions,” Song said. “This is currently a very active area of both research and industrial development. In fact, some hybrid copper-silver methods have already been adopted in commercial heterojunction (HJT) solar cells. At the same time, any large-scale market shift in mainstream cell products will ultimately depend on ensuring that cell and module efficiency, long-term reliability, as well as processing cost and environmental impact, can be well managed.”

Lorenz said screen-printable copper or copper-containing pastes are the most promising method to significantly cut silver use.

“Considering the currently ongoing enormous price level boost of silver, the pressure on the PV industry to reduce silver is currently very high,” explained the Fraunhofer ISE researcher. “This will accelerate the development of new metallization pastes to replace silver with alternative materials like copper and nickel.”

Lorenz added that replacing silver pastes with copper-containing pastes in tunnel oxide passivated contact (TOPCon) solar modules is more difficult due to oxidation, copper in-diffusion, cross-contamination, and module-level reliability issues.

“My anticipation is that the very fast development of new screen/stencil generations to print ever finer contacts with less silver, particularly on the front side, will continue for some time,” Lorenz said. “However, there are limitations for further finger width reduction as the printed fingers are already very narrow. Very interesting are the current developments of fire-through copper paste for TOPCon cells, with the first tests showing very promising results on TOPCon cells. This might be a way to replace silver with copper in the long run.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.