Australia is collaborating with India, Indonesia and the United States to develop a zero-carbon, automated solar panel recycling process using robots to recover ultra-pure silicon.

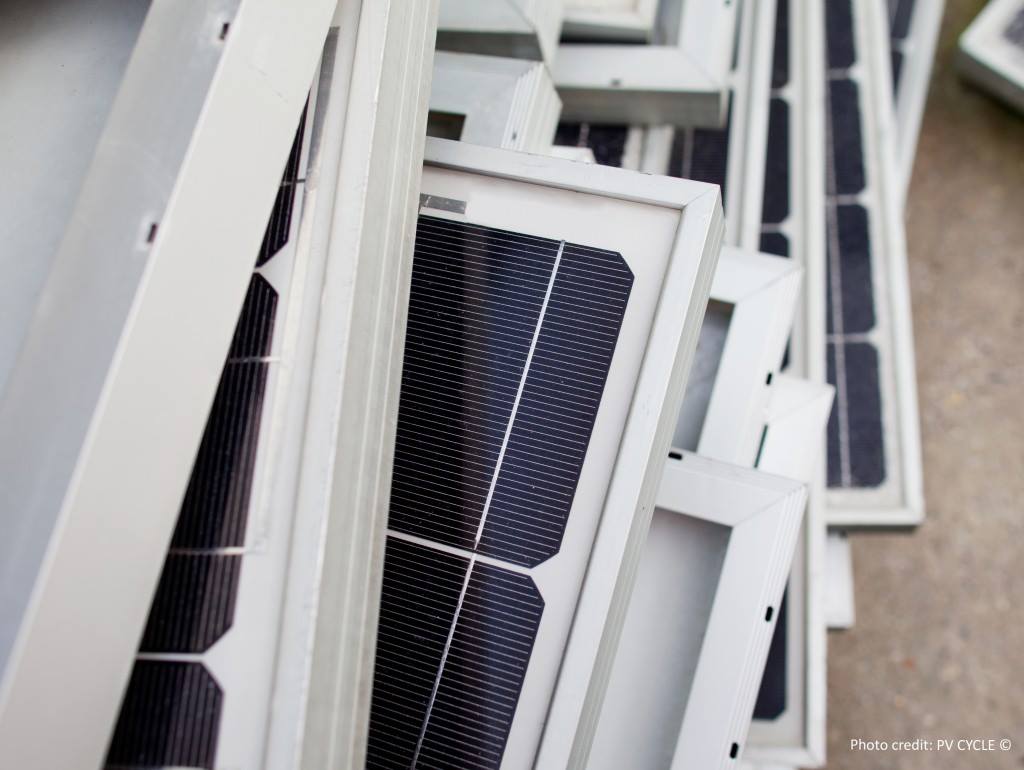

Led by Victoria-based Swinburne University of Technology the aim of the $3 million (USD 1.94 million) joint project is to develop a zero-carbon, automated solar panel recycling process using robots to recover ultra-pure silicon.

Swinburne Professor Akbar Rhamdhani said recycling panels to recover silicon and make new panels is a viable solution to keeping modules out of landfill.

“Silicon is a critical mineral, and we need very high-grade versions of it to produce more solar panels, along with many other technologies,” Rhamdhani said.

“In a traditional process, we use carbon and extremely high temperatures to reduce raw silica to metallurgical-grade silicon. It’s very energy intensive and takes a lot of time. Recycling can bypass this.”

The labour intensive process to dismantle panels and remove wires before extracting 99.99% pure silicon is at the heart of the project’s use of robots, with processing powered by green energy and electricity.

“We are developing a process that is quite clean, with a no or very low carbon footprint,” Rhamdhani said.

The Zero-Carbon and Circular Solar PV Recycling (Si-Zero) program also includes researchers from the Indian Institute of Technology Hyderabad (IIT Hyderabad), Indonesia’s Gadjah Mada University and national research agency Badan Riset dan Inovasi Nasional (BRIN) and the United States-based electrochemistry specialist Sadoway Labs Foundation.

Sadoway Labs brings to the project extreme electrochemistry at temperatures above 540°C for industrial decarbonisation of the process, and IIT Hyderabad also brings technical expertise in high-temperature processing.

It will also develop new methods, such as electro slag refining, in collaboration with Indian clean energy industry partner Greenko, while Swinburne will use its electric refining process that allows for the selective removal of impurities in silicon.

Gadjah Mada University Professor Himawan Tri Bayu Murti Petrus said the initiative enables the Indonesian team to gain technical knowledge in solar panel production and recycling as the country expands its PV manufacturing capacity.

“Through collaboration, Indonesian institutions gain access to frontier knowledge, advanced instrumentation and experimental methodologies,” Petrus said.

Manufacturing costs to make solar modules can also be reduced using recycled materials.

IIT Hyderabad spokesperson Ashok Kamaraj said recycling end-of-life panels can reduce import dependency, cut production costs and lower environmental impact.

“Establishing silicon recovery infrastructure will support a circular economy, strengthen domestic manufacturing, and align with India’s Make in India, clean energy and sustainability goals,” Kamaraj said.

Swinburne researcher Dr Bintang Nuraeni added Si-Zero is the first project of its kind in the world.

“It brings together international expertise to develop zero-carbon processes for recovering high-purity silicon and other valuable materials from end-of-life solar panels, strengthening the foundation for a sustainable and circular solar industry,” Nuraeni said.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

2 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.