Researchers from the Tokyo University of Science (TUS) have found sodium-ion batteries (SIB) using hard carbon (HC) anodes can charge faster than lithium-ion batteries (LIB), challenging long-held assumptions in battery research.

The team sought to address the problem of conventional battery testing commonly underestimating HC’s true charging rate due to issues with concentration overvoltage in composite electrode.

During rapid charging, the dense composite structure of the electrode can cause ‘ion traffic jams,’ where ion transport in the electrolyte limits the reaction speed making the charging rate limit of HC, as well as how the rate of sodium insertion compares to lithium, unclear.

Published findings in Chemical Science called Revealing the Kinetic Limits of Sodiation and Lithiation at Hard Carbon Using the Diluted Electrode Method, outline the TUS research team’s quantitative comparison of sodium and lithium insertion kinetics without electrolyte transport limitations, using a diluted electrode method (DEM).

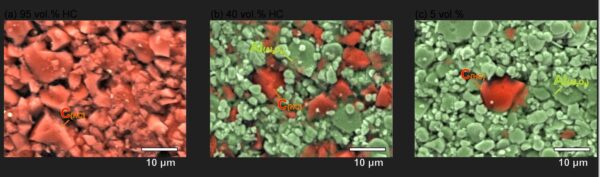

The DEM was pioneered by Osaka Metropolitan University Professor Kingo Ariyoshi whose research found negative electrode active HC powder was partially replaced by aluminum oxide powder, which is electrochemically inactive.

The sodiation process was found to be faster than lithiation for the same hard carbon negative electrode, with the rate-determining step identified as the pore-filling mechanism, where sodium requires lower energy than lithium to form pseudo-metallic clusters in hard carbon nanopores.

This low crystalline, porous type of carbon can store large amounts of sodium, enabling SIBs to reach energy densities comparable to commercial LIBs.

Image: Professor Shinichi Komaba from Tokyo University of Science, Japan, CC BY 2.0

TUS Department of Applied Chemistry Professor Dr. Shinichi Komaba said the results quantitatively demonstrate that the charging speed of an SIB using an HC anode can attain faster rates than that of an LIB.

“A key point of focus for developing improved HC materials for fast-chargeable SIBs is to attain faster kinetics of the pore-filling process so that they can be accessed at high charging rates,” Komaba said.

Along with third-year PhD candidate Yuki Fujii and Department of Applied Chemistry Assistant Professor Zachary T. Gossage, the team’s diluted electrode method involved creating an electrode that combines both HC particles and an electrochemically inactive material like aluminum oxide.

At the appropriate ratio, it ensures that each HC particle is surrounded by an ample supply of ions, eliminating the typical ion transport issues within the electrolyte and at the negative electrode.

Using this approach, the researchers were able to effectively measure and compare the maximum rates for sodiation (sodium insertion), lithium intercalation, and lithiation (lithium insertion) into HC.

Furthermore, sodiation into diluted HC electrode showed comparable rate capability to lithium intercalation at diluted graphite electrodes.

“Our results provided clear and quantitative evidence of HC’s high-rate potential. Through detailed testing and analysis using cyclic voltammetry, electrochemical impedance spectrometry, and potential-step chronoamperometry, the team found that the sodiation process is intrinsically faster than lithiation for the same negative electrode,” Komaba said.

“This was confirmed by calculating the apparent diffusion coefficient—a measure of how quickly ions move through the material—which was generally higher for sodium than for lithium.”

Komaba added that the results quantitatively demonstrate that the charging speed of an SIB using an HC anode can attain faster rates than that of an LIB.

Rate-determining step

Furthermore, the team precisely identified that the rate-determining step for the entire charging process is the pore-filling mechanism, which occurs when ions aggregate to form pseudo-metallic clusters within HC’s nanopores.

While the initial stage of charging (adsorption/intercalation) was found to be very fast for both ions, the speed of the total reaction is ultimately limited by the efficiency of the pore-filling process.

Detailed chemical kinetic analysis revealed that sodium requires less energy than lithium to form these clusters, which helps explain the rate advantages observed. By identifying this bottleneck, this study provides a clear direction for faster and more energy-efficient battery designs.

Komaba said a key point of focus for developing improved HC materials for fast-chargeable SIBs is to attain faster kinetics of the pore-filling process so that they can be accessed at high charging rates.

“Also, our results suggest that sodium insertion is less sensitive to temperature, based on the consideration of smaller activation energy than lithiation.”

The team concludes, their findings suggest SIBs are a cheaper and safer alternative to LIBs, which offer performance advantages in charging speed and could offer more stable operation than LIBs.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.