Ideal Energy (Shanghai) Sunflower Semiconductor has announced the completion of an artificial intelligence (AI)-enabled demonstration line for ultra-thin, flexible heterojunction solar cells (HJT) solar cells designed for space and near-space applications, marking a move beyond conventional photovoltaic manufacturing into advanced, lightweight energy systems.

The company said the pilot line, fully designed and integrated in-house, has successfully produced its first batch of P-type ultra-thin flexible HJT cells that meet internal performance benchmarks.

The announcement was made on 12 January 2026 and subsequently reported by several state and financial media outlets in China.

Ideal Energy, founded in 2013, is a supplier of turnkey HJT production equipment, with experience delivering GW-scale lines. It said the new platform builds on its existing mass-production toolset rather than laboratory-scale systems, positioning the line as a bridge between industrial manufacturing and early-stage technology validation for specialised applications.

The company said the line integrates its established physical vapour deposition (PVD), plasma-enhanced chemical vapour deposition (PECVD) and precision wet-processing modules, adapted for handling and coating ultra-thin silicon substrates.

The system incorporates AI-based process control to optimise critical steps such as low-damage film deposition, wafer transport, and uniformity management, which are considered key challenges when working with thin, flexible cells.

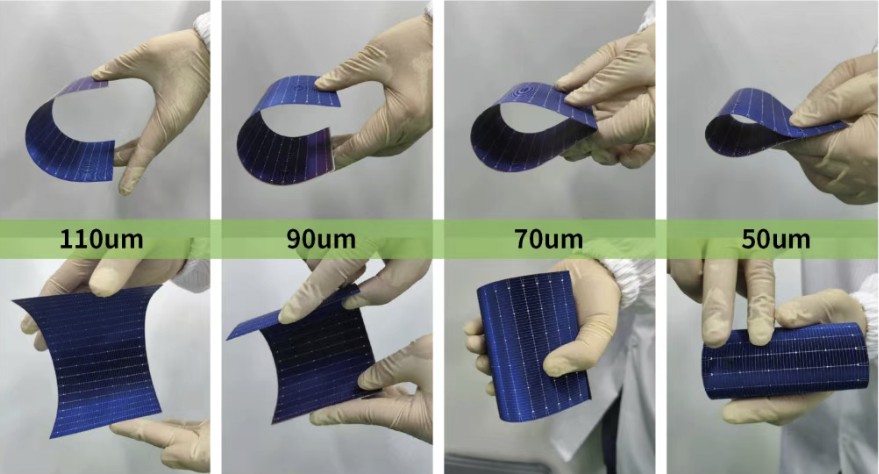

Ideal Energy has not disclosed specific conversion efficiency figures, cell thickness, or production capacity for the line. However, it said the initial output retains the typical advantages of HJT technology, including high open-circuit voltage and low degradation, while achieving mechanical flexibility suitable for curved or rollable form factors.

The company said that the primary design objective is extreme lightweight performance, a key metric for space and high-altitude platforms where power-to-weight ratio directly affects payload capacity and system design.

Flexible HJT modules, in this context, can be deployed on non-planar surfaces and compact structures that are not compatible with conventional rigid glass-based modules.

Ideal Energy added that the cells are engineered to tolerate wide temperature variations and radiation exposure associated with space environments, although it has not released third-party test data or specific qualification standards related to thermal cycling or radiation resistance.

The project has secured backing from its major shareholders, including Shanghai Alliance Investment and Shanghai Electric, which holds a minority stake through its automation engineering subsidiary.

The company said this industrial and capital support has enabled it to combine equipment development, process optimisation, and application-oriented system design on a single platform.

State media reports described the pilot line as China’s first AI-enabled demonstration platform specifically oriented toward ultra-thin flexible HJT cells for space use, though the company has framed it primarily as a technology validation and prototyping facility rather than a commercial production line.

Ideal Energy said the platform will initially focus on process verification and sample delivery for potential aerospace and high-altitude energy applications. It has not named downstream partners or provided a timeline for scaling the technology toward volume manufacturing.

The company added that the long-term objective is to establish a standardised manufacturing pathway for flexible HJT cells that can transition from niche aerospace applications to broader high-value markets where weight, form factor, and reliability are critical performance parameters.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.