Sydney-headquartered subsidiary of Spanish company, PVH, PV Hardware (PVH) Australia has developed a 95% Australian-made steel tracker supply chain setting a new benchmark for local manufacturing in the renewable energy sector.

To achieve the outcome, PVH Australia has partnered with New South Wales (NSW) steel cutting company Precision Oxycut, part of the Sell & Parker Group, and Sydney based steel producer Infrabuild.

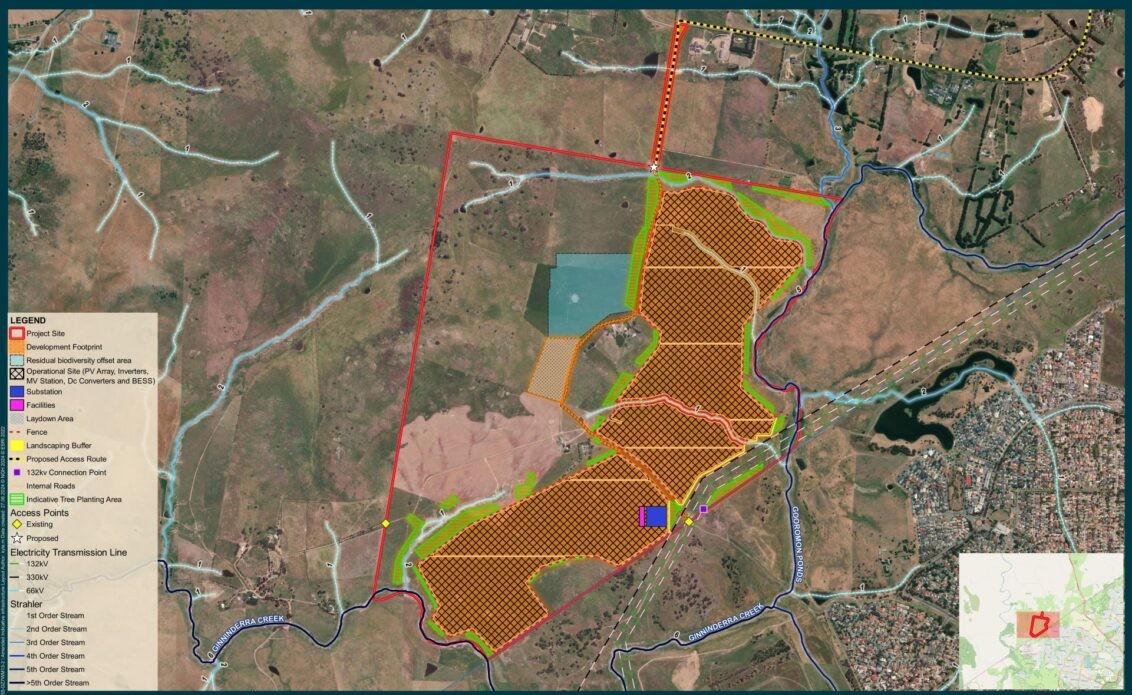

For developers bidding into the Victorian Renewable Energy Target Auction (VRET2), Renewable Energy Zones (REZ), and Capacity Investment Scheme (CIS) tenders, the Australian-made steel tracker supply chain increasingly meets Australian steel content and domestic manufacturing compliance.

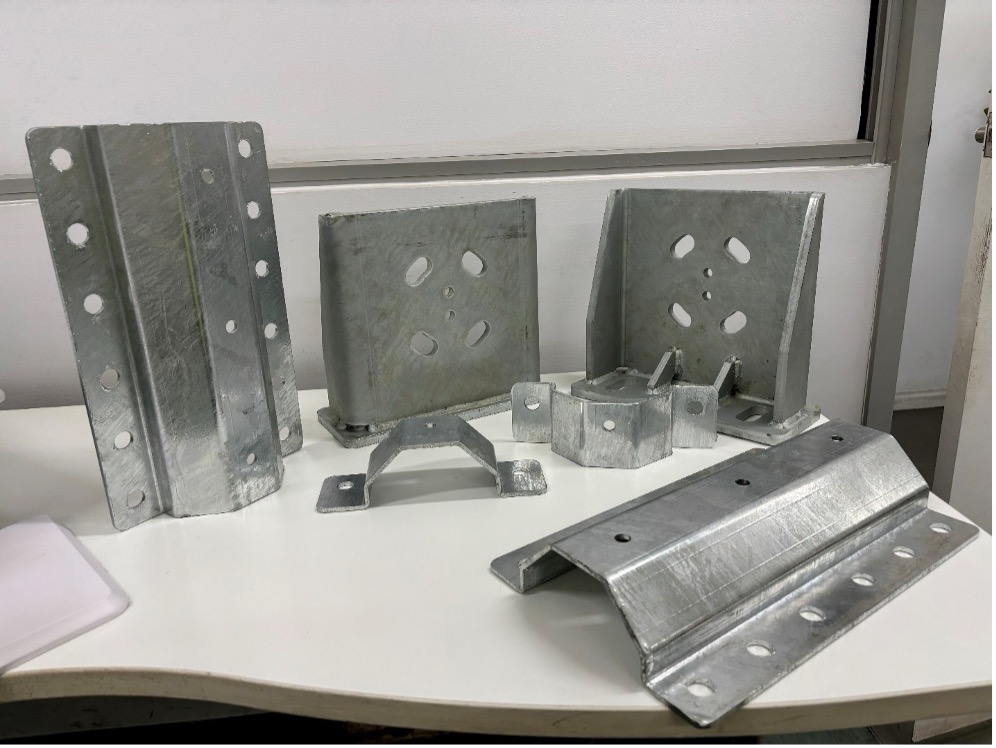

Critical elements include piles, torque tubes, motor brackets, and splices, are now produced entirely in Australia.

A company statement says it provides developers and EPCs with a tracker solution that is audit-ready, fully traceable, and engineered specifically for Australian conditions.

“In a tender environment where certainty matters, PVH’s local manufacturing model removes ambiguity from steel origin, supply chains, and documentation,” the statement says.

PVH Australia Vice President Trevor De Vries said the company’s mission is to empower customers to win tender bids.

“Our clients need certainty around local content, steel origin, and supply-chain strength. Our 95% Australian-made tracker solution delivers exactly that—backed by robust local manufacturing, full traceability, and the confidence to meet the most stringent tender requirements,” De Vries said.

The high-local-content manufacturing model ensures compliance with Australian-made steel requirements, reduces logistics and import risk, maximises local content and economic contribution scoring, and provides full transparency and audit-ready documentation.

Precision Oxycut Managing Director Simon Preston there is no other tracker company on the market that has a workable solution to Australia’s 95% local content targets.

“We are proud to be aligned with PVH, who not only deliver a great product but also care deeply about the social licence, the local workforce, and the communities they operate in,” Preston said.

Infrabuild National Business Development Manager – Group Manager Duane Cornish said the Fulham project is a strong example of what can be achieved when local manufacturing is backed into the renewable energy supply chain.

“Producing torque tube here in Australia supports regional jobs, strengthens capability, and gives developers confidence that high-quality steel can be sourced locally at scale,” Cornish said.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.