New technologies, new opportunities

UK-based analyst Exawatt and Germany’s Nexwafe published a white paper this week that takes a close look at the current state of PV manufacturing worldwide, and how Nexwafe’s innovative wafer production tech might fit into it. They said that if the potential of its Epiwafer can be realised, the PV industry may yet see “another revolution in wafer manufacturing.”

Weekend read: Expansions in n-type

The past 12 months have been a turbulent time for PV manufacturing. Rapid and impressive developments in technology have been accompanied by price increases up and down the supply chain, and energy shortages weighed on production in the second half of the year. Chinese n-type module manufacturer Jolywood is now pressing ahead with ambitious expansion plans despite the disruption. pv magazine publisher Eckhart K. Gouras and editor Mark Hutchins recently caught up with Cathy Huang, European sales director at Jolywood, to discuss the company’s plans to bring n-type TOPCon technology into mainstream production.

Doped carbon for a reliable lithium sulfur battery

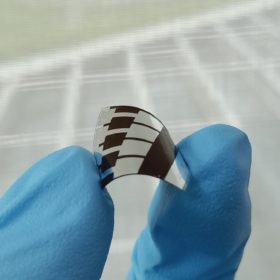

Scientists in South Korea developed a porous carbon material that, when applied as a coating to the separator film in a lithium-sulfur battery, was shown to reduce an unwanted side effect and improve the battery’s performance and reliability. The coating is based on methylene blue, a type of salt commonly used in textile dying.

Powering up PERC-perovskite tandem cells

Perovskite-silicon tandem cells offer one of the surest pathways to much higher solar efficiencies, one that has moved close to commercialisation in the past few years. Much of the work getting to this stage has naturally focused on developing a viable perovskite top cell. Optimisations to the silicon layer underneath, however, will also be important to the overall device function and efficiency. Scientists in Germany examined five different silicon cell concepts similar to those in mass production today, finding that with a few optimisations these could reach efficiencies up to 30.4%.

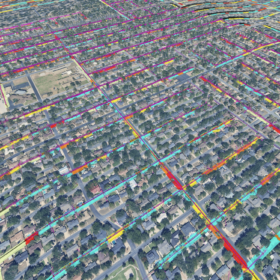

Grid stability and 100% renewables

New research from Stanford University professor Mark Jacobson seeks to remove any doubts about grid stability in a world powered entirely by renewable energy. The latest study models 100% wind water and solar powered grids across the United States, finding no risk of blackouts in any region and also broad benefits in cost reduction, job creation and land use.

Google lends a hand in the search for new solar cell designs with open-source tool

Scientists in the United States developed a computer simulator that can calculate the conversion efficiency of different solar cell materials and configurations – helping to guide research and optimisation of new cell designs. The simulator is available to researchers as an open-source tool to save time and spot the best opportunities for optimisation of any given approach.

Behind the price drops in lithium-ion batteries

Scientists in the United States pieced together data from hundreds of different sources, looking to establish the key factors that have led to consistently falling prices for lithium-ion technology since their commercialisation thirty years ago. They find that public-funded research, primarily in chemistry and materials science, has made the largest contribution to cost reduction. And they offer suggestions on policy and investment to ensure that the research can continue to make these important contributions to reduction in battery costs.

Mathematical model to predict rooftop PV system yield

Scientists in India developed a mathematical model to predict the output of solar cells and modules in the field. The model was developed and tested using both sun simulator and actual installed modules. The scientists state that their model can be applied to a PV installation anywhere in the world, and that by taking into account module degradation over time their forecasts can be as much as 26% more accurate than existing energy yield models.

Big modules head for standardisation

PV manufacturing giant Trina Solar says it has agreed with other industry players on a set of standard dimensions and other technical specifications for PV modules utilising 210mm wafers – the largest currently available on the market. The manufacturer says it expects the China Photovoltaic Industry Association to formally release the standard before the end of October.

Umicore to purchase 42,000 tons of Australian lithium battery material

Belgian materials company Umicore has signed a contract with Australia headquartered Vulcan Energy Resources to purchase up to 42,000 tons of lithium hydroxide over a five year period beginning in 2025. The material will be used in Umicore’s production of cathode materials for lithium-ion cell manufacturers.