Sunday read: China struggles with solar supply

Since July 2020, the PV industry has been experiencing price rises, which have affected almost all the components in a solar system. As these price increases spill out into higher installation costs, we see end user prices for solar rising for the first time in 10 years, threatening the competitiveness of PV in certain markets. Vincent Shaw reports from Shanghai on solar manufacturing’s supply chain crisis.

Factory explosion in Xinjiang threatens further polysilicon shortage

With the solar industry already seeing prices rise because of a shortage of panel raw material polysilicon, an explosion yesterday at the factory of a silicon metal producer in Xinjiang could have further repercussions on supply. No casualties have been reported.

Growatt launches new inverter for commercial and utility-scale projects

The new product has an efficiency of 98.8% and a European efficiency of up to 98.5%. It features 10 independent maximum power point tracking (MPPT) inputs, with MPPT voltage ranging from 180-1000 V.

Are oil and gas companies on the run?

Private sector fossil fuel spending on exploration is drying up just as modest rises in clean energy investments are being observed. With stock market investors increasingly embracing renewables, the IEA has observed positive signals in its latest energy investment report, but warned we are still doing far too little to keep global heating at bay.

Flexible bifacial kesterite solar cell at 9.3% efficiency

Scientists in China developed a new kesterite solar cell they say could be suitable for indoor or outdoor applications. The bifacial solar cell reached 9.3% frontside efficiency, and also achieved a 9.0% on the backside.

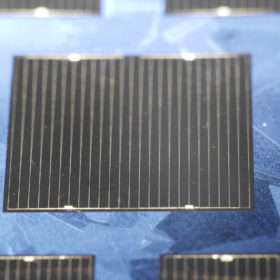

JinkoSolar reaches record 25.25% efficiency with n-type monocrystalline TOPCon solar cell

The Chinese module manufacturer said the 0.35% improvement in efficiency was obtained through material upgrades integrated into the cell process and fabrication. The result was confirmed by China’s National Institute of Metrology.

Sunday read: Life after PERC

The pursuit of higher conversion efficiencies is an eternal theme in the PV industry. Among all the links in the chain, cell technology is the most fundamental and decisive element. As we look beyond the established PERC technology, whether heterojunction or TOPCon will become the dominant “next-gen” solar cell among China’s manufacturing giants is emerging as a balancing act between incumbent and upstart, reports Vincent Shaw from Shanghai.

Global solar supply chain remains under scrutiny

The discussion about the extent to which forced labor exists in the solar value chain continues. A video, a university report, a ministerial response and a parliamentary machinations formed notable developments of the debate last week.

Australia-China relations continue to sour

Last week’s announcement by China’s National Development and Reform Commission (NDRC) that it has indefinitely suspended all high-level economic dialogue with Australia indicates Beijing’s increasing willingness to target trade in its dispute with Canberra. With China buying around a third of everything Australia exports on a value basis, the downward spiral in Sino-Australian diplomatic relations is clearly of concern.

Saturday read: New applications see surge in Chinese demand

China’s project development segment is dynamic, to say the least. Having undergone significant changes toward a “subsidy-free” footing, developers are now facing requirements to integrate storage, deploy hybrid arrays, and pursue self consumption through BIPV and agrivoltaics applications, writes Frank Haugwitz, the director of the Asia Europe Clean Energy (Solar) Advisory (AECEA).