Though its potential for low-cost, high efficiency solar cells is well known within the industry, issues with stability, defects and moisture sensitivity have kept perovskite PV largely confined to research laboratories.

Solliance, however, is one of a few organizations working on industrially applicable processes for the material, and has hit a new milestone in its research. The group has previously developed a roll to roll process for the production of perovskite modules, and this week published new maximum efficiency records of 13.5% for individual cells measuring 0.1cm², and 12.2% on a module measuring 10.5cm².

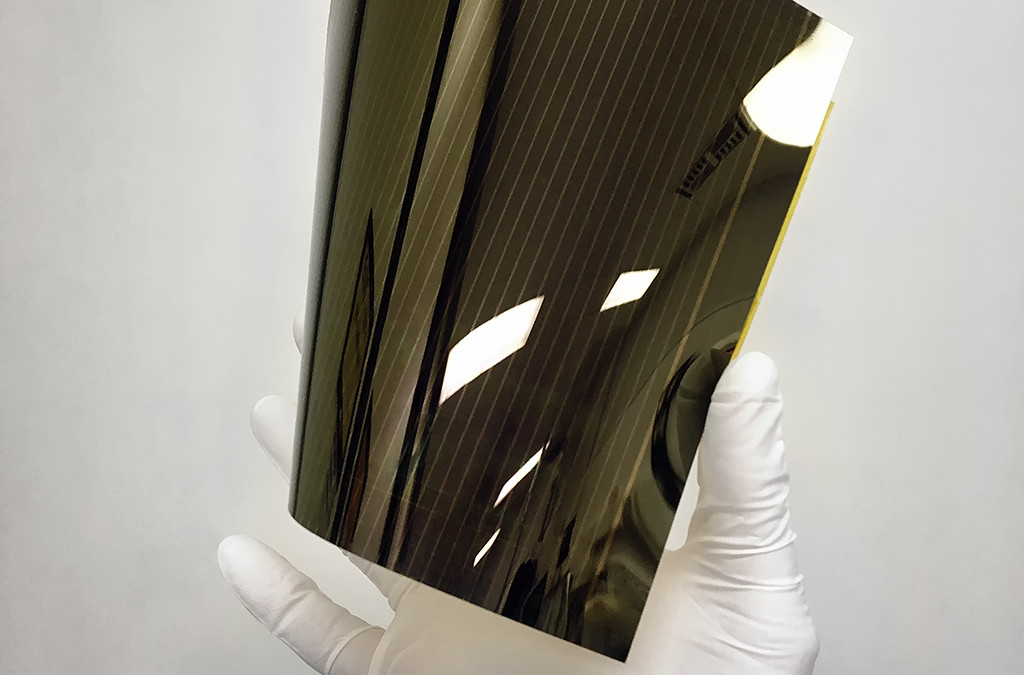

The researchers selected a 10-meter segment of foil with ‘visually good perovskite quality’ and used this to fabricate multiple zones, each consisting of 20 individual 0.1cm² solar cells. The maximum stabilized efficiency of 13.5% was measured under maximum power point tracking conditions for a period of five minutes. These results represent approximately a 1% improvement over the group’s previous results, reported earlier in 2017.

At module level, the group produced 22 modules of varying size, and hit the maximum efficiency of 12.2% on the smallest, measuring 4cm². Average efficiency for these small modules was 11.1%. The largest module fabricated by Solliance measured 160cm² and achieved an aperture stabilized efficiency of 10.1%.

While these results are still far from the size and efficiencies seen in today’s commercial solar panels, Solliance is keen to stress the potential and scalability of its process. “These results show that the developed R2R process is very reproducible over different runs in time, which is very important for future reliable manufacturability,” says Pim Groen, Program Manager for Solliance and Professor of SMART materials at the Netherlands Technical University of Delft.

The group is confident in its process, and expects to be able to continue improving it, to ultimately produce commercially viable perovskite products at scale in the future. “We are confident of quickly boosting efficiencies above 15% for modules up to 30x30cm²,” says Solliance Program Director Ronn Andriessen.

While perovskite solar cells have achieved impressive efficiencies in the lab setting, issues with their stability, and a tendency to quickly degrade under operating conditions have been a key factor holding back commercialization. While Solliance has not published any detail regarding this aspect of performance, Andriessen also stated that “Our research shows that optimizing materials and processes is steadily improving the stability of perovskite devices under real life operational conditions.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.