The birthplace of PERC solar cells, the University of New South Wales, is looking to take its trademark solar technology to the next level.

The UNSW School of Photovoltaic and Renewable Energy Engineering has joined forces with Leadmicro, a China-based global manufacturer of advanced solar cell machinery, to develop a new process for PERC solar cells using a technique called Atomic Layer Deposition (ALD).

Developed at UNSW in the 1980s by pioneering solar researcher Martin Green, Passivated Emitter and Rear Cell (PERC) technology has already proved the advantage of its ultrathin films, which reduce electronic losses at the rear of the solar cell ensuring greater efficiency.

The new research project will aim to construct these ultrathin layers by using ALD technique, where nanoscopic-thin films within the solar cells are built one atomic layer at a time, which gives engineers very precise control over the design process.

“The photovoltaic industry is currently amid a transfer to PERC technology,” said Associate Professor Bram Hoex, who is leading the project at UNSW, noting that the team expects to further improvements to the efficiency of PERC solar cells by using ALD technology.

ALD could potentially reduce the production cost of PERC solar cells, by delivering higher throughput and lower equipment Capex. Currently, Plasma-enhanced chemical vapor deposition (PECVD) is most commonly deployed for the rear-side passivation of PERC cells. Switzerland’s Meyer Burger is the largest supplier of PERC solutions. The application of ALD for PERC upgrades or new cell lines could have a significant impact on PERC cell production.

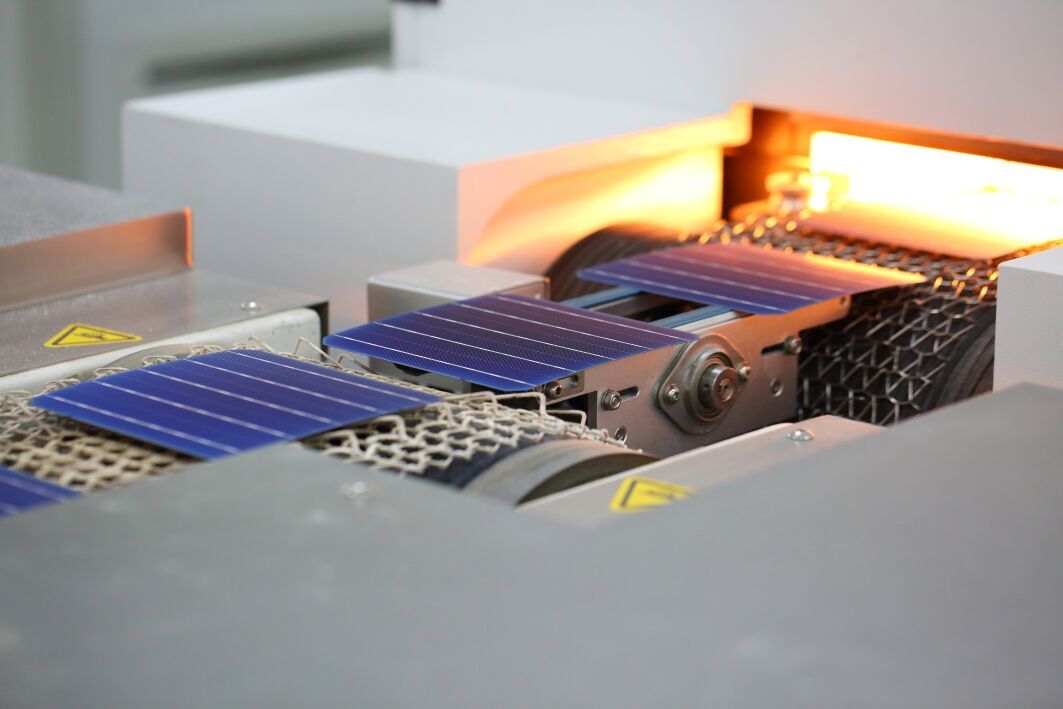

Image: UNSW

The current potential conversion rate of laboratory PERC solar cells can reach 25%, compared to the traditional solar cell technology’s 20%. Hoex and team are looking to develop innovative nanoscale layers which will increase the potential conversion rate of silicon solar cells to over 27%.

“While it may sound like a modest increase in efficiency, this would be an 8% relative increase, which is likely to be achieved without a significant increase in costs, thus further reducing the overall cost of solar electricity,” Hoex said.

The project is partly funded by an Australian Renewable Energy Agency (ARENA) grant to ensure the new technology can go directly into mass production, without driving up costs.

To make all this happen, Leadmicro will donate a $1 million ALD reactor to UNSW that it says resembles those used by their high-volume manufacturing clients in China. This will make it possible for the researchers to quickly test and adapt the improved solar cells for commercial use.

“Collaborations such as this one between researchers and industry, where prototypes can be tested before being placed into full-scale production, are crucial to driving the economic benefits of discoveries,” UNSW Dean of Engineering Mark Hoffman said.

Leadmicro expects to install the ALD reactor at UNSW’s Solar Industrial Research Facility in Kensington by March 2019, with the view to having the next generation PERC solar cells in production in late 2019.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.