A research team led by Associate Professor Daniel Gomez, an Australian Research Council-funded Future Fellow, today published a paper — Hot-carrier organic synthesis via the near-perfect absorption of light — in the journal ACS Applied Energy Materials, which addresses the challenge of identifying alternative energy sources for chemical manufacturing.

Plastics, medicines, fertilisers and components of electronics (materials that produce the colours on digital screens) are among the products that could be manufactured using photocatalysis — the application of light, and soon sunlight — to drive chemical reactions.

“Our ultimate goal is to use this technology to harness sunlight efficiently and convert solar energy into chemicals, with the aim of transforming this vital industry into one that’s renewable and sustainable,” says Gomez.

According to the August 2018 Australian Energy Update, chemical production in Australia uses 17.8% of the total energy used in manufacturing, and manufacturing itself makes up 17.8% of our overall energy consumption. In the US, chemical manufacture makes up 28% of electricity used by the country’s industrial sector.

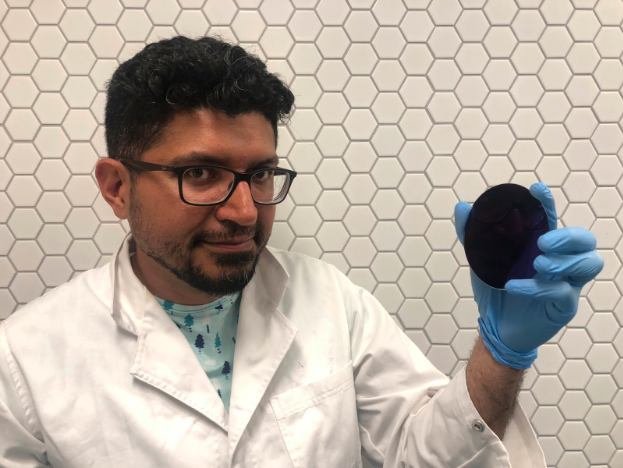

The RMIT group’s breakthrough centres on enhancing the optical properties of palladium nanoparticles enabling higher rates of light absorption. A rare, and expensive white metal, palladium is an excellent catalyser of chemical reactions, but is not very responsive to light. The process developed at RMIT in collaboration with CSIRO, the Melbourne Centre for Nanofabrication and the University of Melbourne, manipulates palladium to absorb 99% of light.

“It uses the properties of optical materials to suppress reflection — so light is not reflected off the particle surfaces, but is completely absorbed,” says Gomez.

“In photovoltaics,” he adds, “you use sunlight to produce charges”. In this application, “those charges do not give an electrical current, instead they initiate a chemical reaction.”

Gomez says he first thought of the process as a way to produce small volumes of complex chemicals used by pharmaceutical companies in the manufacture of medicines. “My rationale was that materials like palladium are expensive, so I didn’t think it was realistic to deploy these technologies for making tonnes of hydrogen, for example.”

In fact, Gomez’s CSIRO collaborators are already applying his technology, which requires minuscule amounts — mere nanometres — of palladium, to the production of hydrogen. And it is also being considered as a potential method for desalination of water: “The heat localised in the particles can become significant enough to vaporise water,” says Gomez, which leaves the resulting condensate salt free.

Hydrogen production is generating its own heat this year, with Federal Labor leader Bill Shorten having announced his party’s National Hydrogen Plan with investments of $1.14 billion promised to make Australia a world leader in the industry.

Gomez’s work towards harnessing sunlight for photo catalysis is not only efficient in its process, but in its method. He says that Merck, one of the largest pharmaceutical companies in the world, is successfully using heat from compounds of iridium to catalyse chemicals, but that the compounds must be extracted from the processed chemical and then discarded. In the RMIT process, “The materials are in the form of a film, so once you’ve finished the process, you remove the film, clean it and use it again.”

Gomez surmises that over time some chemicals may irreversibly bind to the surface of the film, making it less effective, but the limits of its rinse-and-repeat durability are yet to be explored.

He says next steps include more cheaply producing the nanoparticle film as inks that can be painted onto backing material such as slides, for immersion in raw materials. The depositions are currently produced in vacuum chambers, which have a high cost of operation. Making them into paint-on substances, “will allow us to scale up in a way that is cheaper,” says Gomez.

Meanwhile, he says, “our partners at CSIRO are working on hydrogen production.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.