While it presently may not be economic to use recycled material for lithium ion batteries, it is foreseeable that, as demand from the rapidly developing electro-mobility and energy storage industries grows, it does become so in the near future.

Joining the ranks of companies seeking to ‘close the loop’, the ASX-listed company, Neometals, has commissioned the first stage of its lithium-ion battery recycling pilot project in Canada.

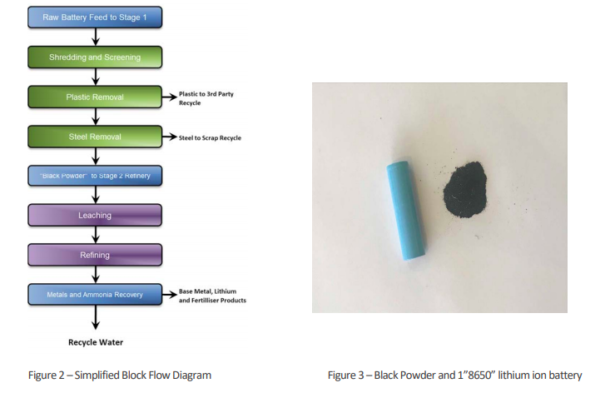

The project is carried out in two stages. Stage 1 involves shredding spent but still charged batteries, removal of metal casings and plastics, with the goal to produce a concentrate referred to as black powder – a mixture of high value cobalt, nickel and lithium compounds as well as shredded copper and aluminium foil. In Stage 2, the black powder is subjected to hydrometallurgy recovery and refining to deliver high‐purity battery materials for market qualification.

A showcase facility

According to the Perth-based company, the feed preparation aspect has now been successfully commissioned using two tonnes of batteries.

“We are delighted to see our battery recycling project back on track. The commissioning of the pilot represents a significant milestone and marks the culmination of extensive research and development into a flowsheet to process multiple battery chemistries, from consumer electronics to electric vehicle applications,” Neometals Managing Director Chris Reed said.

While very low lithium recovery rates have been reported even in state-of-the-art recycling facilities, Neometals says it has developed a process flowsheet to recover >90% of all battery materials from consumer electronic batteries, as well as EV and stationary storage battery chemistries.

The pilot program aims to provide essential data required for a front-end engineering design study, which will support a subsequent feasibility study and potentially pave the way to an investment decision on a commercial plant.

“With ever increasing volumes of commercial LIBs reaching their end of life, we are focussed on proving at scale, then qualifying our scale‐able and modular recycling solution with industry as early as possible. The pilot will serve as a showcase facility for potential partners as well as provide strong independent data for future engineering and financial studies,” Reed explains.

The Canadian branch of Swiss technical services company SGS has been contracted by Neometals to build and operate the pilot at a special facility in Lakefield, Ontario, where it will carry out both battery shredding and dismantling and subsequent hydrometallurgical processing and refining.

In Australia, Neometals has proposed a lithium refinery nearby to Kalgoorlie-Boulder, WA, where tight electricity supply is seen as a hurdle. The plant with a nominal capacity of 10,000 tons is scheduled to begin production from mid-2021, subject to a final project investment decision mid this year.

In December, the company pocketed about $104 million from divesting its 13.8% interest in the Mt Marion Lithium Project in Western Australia.

Thus far, there are no plans to establish a similar battery recycling facility on the home turf. Meanwhile, the nation’s only PV recycling company, SA-based Reclaim PV, has pledged to open its first commercial solar-panel recycling plant in mid 2019.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Instead of mucking around with battery recycling & numerous other peripherals, this company should focus on Barrambie!