The ever-declining cost of Lithium-ion batteries has seen application of systems for energy storage in the United States burgeon from 1 MW to almost 700 MW over the past decade, but little research has been conducted to guide effective fire protection strategies for this addition to commercial operations, according to a report just released by FM Global commercial property insurer and risk-management consultancy.

“These systems hold enormous promise for clean energy while raising new protection challenges,” said Benjamin Ditch, senior lead research engineer at FM Global, in a statement accompanying the report on real-to-life testing that was conducted in stages at the company’s Research Campus, which houses the world’s largest fire technology lab.

Late last year, an Australian Energy Storage Market Analysis published by the Smart Energy Council estimated that under a high-growth scenario, around 450,000 energy-storage systems could be installed in Australia by 2020, installation of commercial systems in the 10-100 kW range had already increased by 91% between 2016 and 2017, and of the 184 battery-storage products then available on the Australian market 62% were Lithium-ion-based technologies.

“The main difference between Li-ion and other battery chemistries such as lead-acid, is the potential for thermal runaway reactions,” explains the introduction to the FM Global report; such reactions can lead to leakage of ignitable gases and subsequent combustion.

The first phase of fire risk-mitigation research, carried out in collaboration with the independent, non-profit organisation Property Insurance Research Group (PIRG) and the Fire Protection Research Foundation in the US, conducted a fire-hazard assessment of ESS and developed safe installation practices, fire protection guidance and emergency response tactics for Li-ion battery energy storage systems.

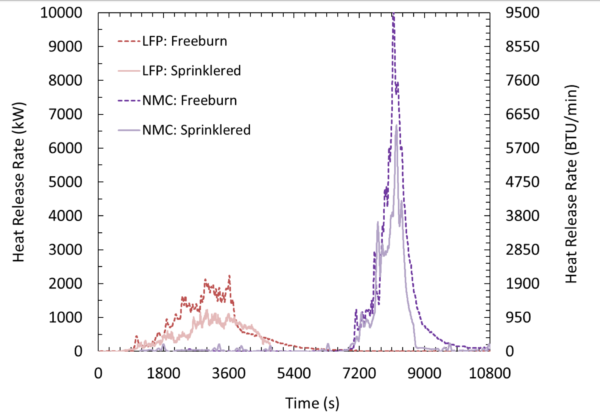

Testing in this latest phase focused on ESS comprised of either iron phosphate (LFP) or nickel manganese cobalt oxide (NMC) batteries, and assumed that the batteries were operating under so-called “abuse” conditions — that is, that proprietary battery-management systems which would normally reduce the fire hazard were not activated.

Test scales ranged from a single battery module to full ESS racking containing 16 modules each. Overall, LFP batteries were found to pose a lower hazard, and water delivered by sprinkler was identified as the most effective fire suppressant tested on either technology.

Graph: GM Global, "Development of Sprinkler Protection Guidance for Lithium-Ion-Based Energy Storage Systems" report.

Key findings from the testing which involved “small- to large-scale fire tests on ESS sized for commercial applications such as manufacturing, office-building power generation and utility use” are that:

- Sprinklers are effective in delaying or preventing fire spreading to adjacent racks.

- Separation between ESS and other combustibles is essential for effective fire protection.

- In the event of a fire caused by ESS, a fire watch should be maintained until all potentially damaged ESS equipment containing lithium-ion batteries is removed from the area.

This last recommendation is the result of understanding that fires involving Li-ion batteries “are known to reignite any time from minutes to days after the initial event”, and that, “Adequate cooling of the batteries is necessary in order to prevent reignition.”

Although the research is intended to inform fire codes and authorities with jurisdiction, the specific guidelines — relating to the positioning of sprinkler systems, required discharge density of water, and space separation of ESS from combustible and non-combustible objects — are available in the FM Global report, Development of Sprinkler Protection Guidance for Lithium Ion-Based Energy Storage Systems on the FM Global technical reports portal.

In commercial and industrial applications, says Ditch, “Our research shows that ESS deployments can be made safe through the combination of automatic sprinklers and careful ESS rack spacing.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

3 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.