pv magazine Australia: What’s new in the Tiger Series module?

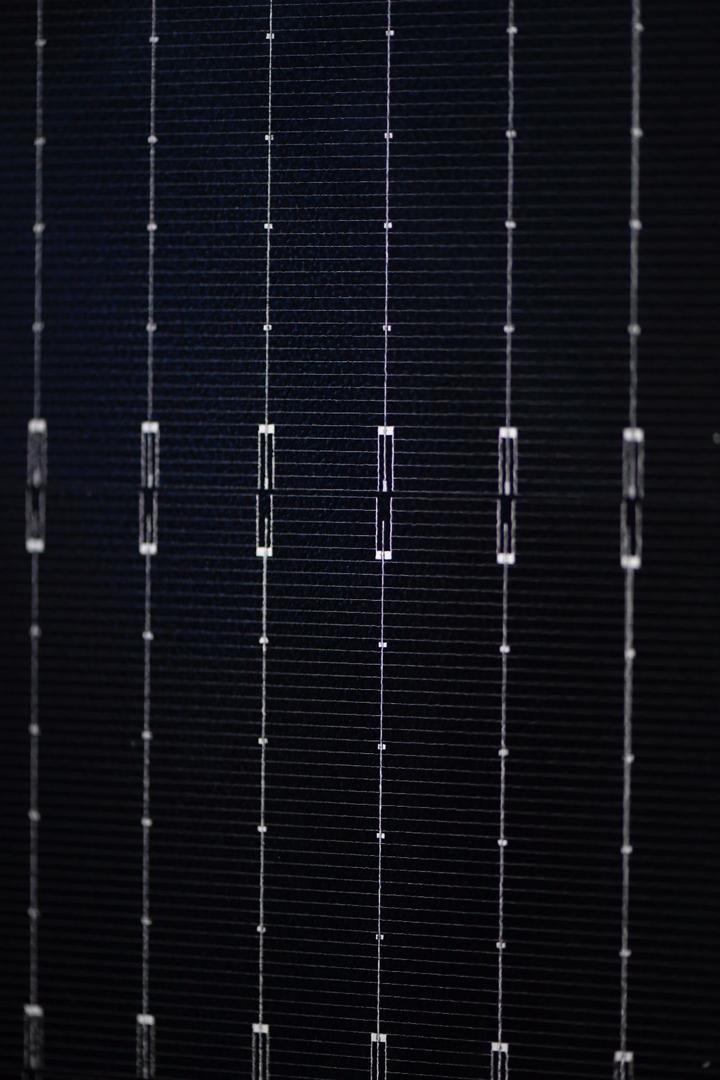

Jeff Zhou: The Tiger has three key features: first is that it deploys nine busbars (9BB), second is half cut cells, and third feature is tiling ribbon (TR) technology. In normal modules, the distance between cells is around 2mm, which means the module area is not fully used. That is why we overlap the cells to make the Tiger Series higher energy density and lower LCOE. This is a major benefit that Tiger Series can provide to our customers.

Why did you choose Australia to launch such a product?

If you look at the [solar] LCOE trends globally, the Australian market is among the top. As we know the labor costs in the Australian market are high. Our Tiger Series delivers 20.78% mono-facial efficiency, and a power output of 460 W in a 78 cells format.

This means that for a project you can use far fewer modules. As a result this means a reduction of labor costs and a decrease in construction time. And the BoS [reduction] benefit, as with other high efficiency products, is also notable. That is why we believe our Tiger can give benefits to customers.

But doesn’t it, by overlapping cells, introduce material inefficiency? I mean, you are covering up part of the cell.

For us, we are customer orientated and we want to provide the most optimized product to customers and actually we do well quality control internally by ourselves.

How long was the Tiger in development?

We prepared for almost one year for this moment.

What kind of production capacity will you have for this module?

We have several GW for the Tiger Series. Actually, any expansion of this would depend on the market demand.

When will Tiger be available?

Mass production will arrive in first half of 2020.

Besides the overlapping of the cells, what else delivers the high performance?

Besides of the super high power, the Tiger also has the better field test performance because light absorption will be reutilized by circular ribbon, as well as superior low irradiance performance due to series resistance. This gives higher energy output during operation.

What’s been the reaction to the new module?

Customers have been really impressed. We just launched our Swan Series at the SNEC [in Shanghai, in June], which achieves 415 W. Now less than half a year we launch our Tiger Series. This is just more evidence that Jinko is always a technology leader. There is high demand for high power modules – to achieve to low LCOE. These new modules mean that we can play a role to supply this and speed up global grid parity of solar.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.